Interaction Diagram - Tied Reinforced Concrete Column (Using CSA A23.3-14)

Interaction Diagram - Tied Reinforced Concrete Column (Using CSA A23.3-14)

Interaction Diagram - Tied Reinforced Concrete Column

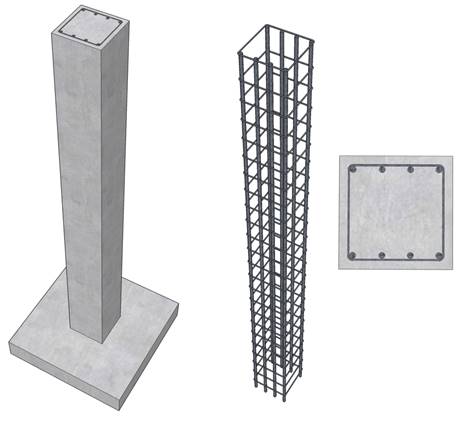

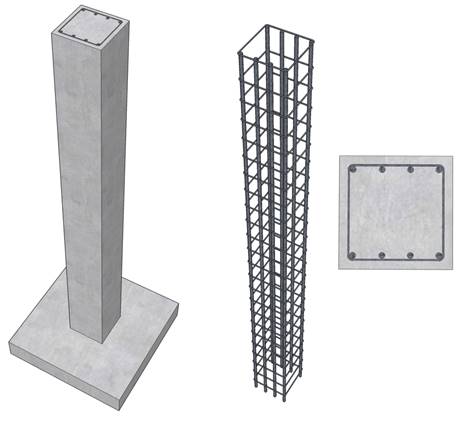

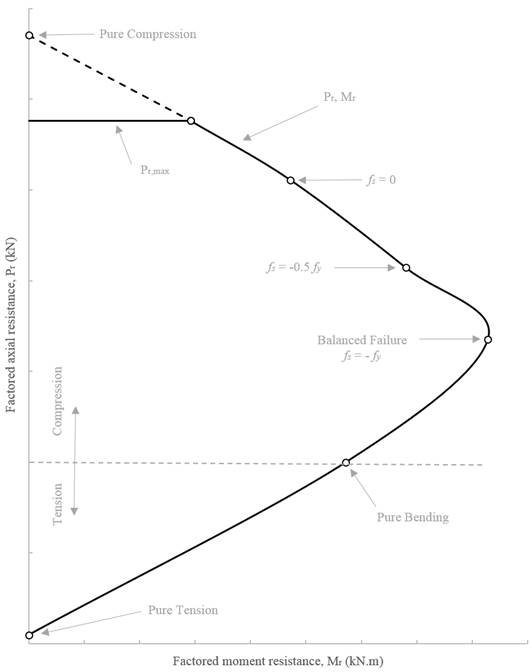

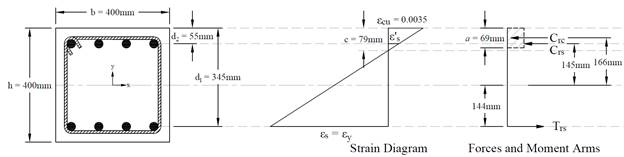

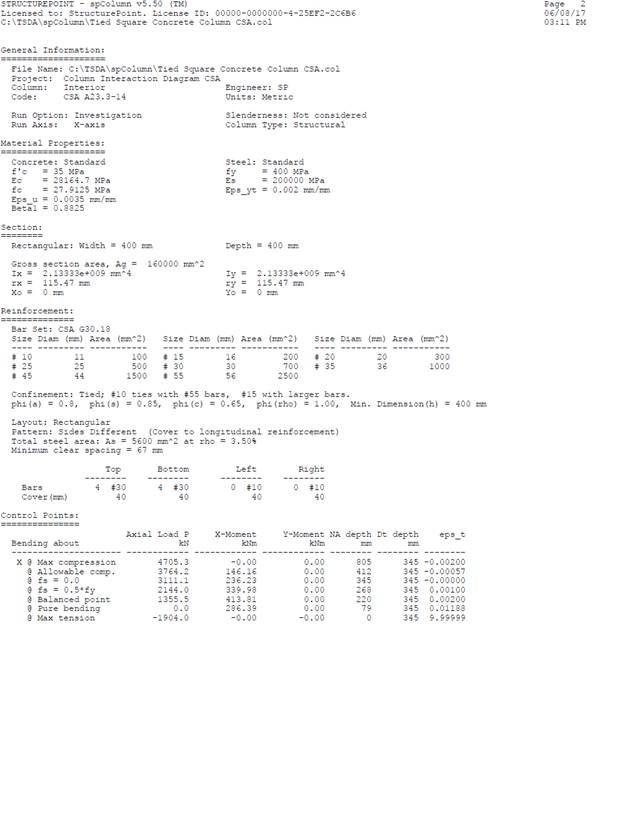

Develop an interaction diagram for the square tied concrete column shown in the figure below about the x-axis using CSA A23.3-14 provisions. Determine six control points on the interaction diagram and compare the calculated values in the Reference and with exact values from the complete interaction diagram generated by spColumn engineering software program from StructurePoint.

Figure 1 – Reinforced Concrete Column Cross-Section

Contents

1.1. Nominal axial resistance at zero eccentricity

1.2. Factored axial load resistance at zero eccentricity

1.3. Maximum factored axial load resistance

2. Bar Stress Near Tension Face of Member Equal to Zero, ( εs = fs = 0 )

2.1. c, a, and strains in the reinforcement

2.2. Forces in the concrete and steel

3. Bar Stress Near Tension Face of Member Equal to 0.5 fy, ( fs = - 0.5 fy )

3.1. c, a, and strains in the reinforcement

3.2. Forces in the concrete and steel

4. Bar Stress Near Tension Face of Member Equal to fy, ( fs = - fy )

4.1. c, a, and strains in the reinforcement

4.2. Forces in the concrete and steel

5.1. c, a, and strains in the reinforcement

5.2. Forces in the concrete and steel

6.1. Strength under pure axial tension (Prt)

6.2. Corresponding Moment (Mrt)

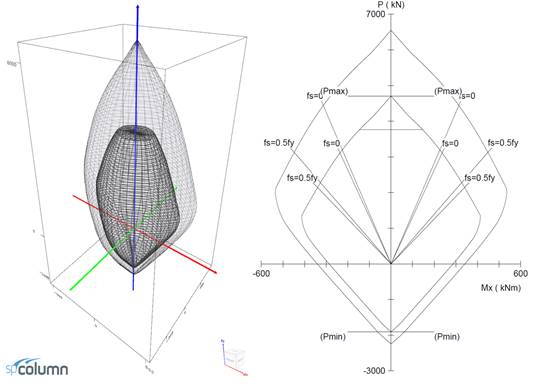

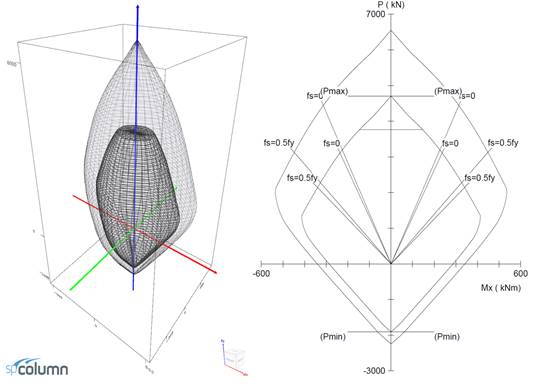

7. Column Interaction Diagram - spColumn Software

8. Summary and Comparison of Design Results

Code

Design of Concrete Structures (CSA A23.3-14)

Reference

Reinforced Concrete Mechanics and Design, 1st Canadian Edition, 2000, James MacGregor and Fred Michael Bratlett, Prentice Hall Canada Inc.

Design Data

fc’ = 35 MPa

fy = 400 MPa

Cover = 55 mm to the center of the reinforcement

Column 400 mm x 400 mm

Top reinforcement = 4 No. 30

Bottom reinforcement = 4 No. 30

Solution

Use the traditional hand calculations approach to generate the interaction diagram for the concrete column section shown above by determining the following six control points:

Point 1: Pure compression

Point 2: Bar stress near tension face of member equal to zero, ( fs = 0 )

Point 3: Bar stress near tension face of member equal to 0.5 fy ( fs = - 0.5 fy )

Point 4: Bar stress near tension face of member equal to fy ( fs = - fy )

Point 5: Pure bending

Point 6: Pure tension

Figure 2 – Control Points

![]()

![]() CSA

A23.3-14 (Equation 10.1)

CSA

A23.3-14 (Equation 10.1)

![]()

Since this column is a tied column with steel strain in compression:

![]() CSA

A23.3-14 (Equation 10.11)

CSA

A23.3-14 (Equation 10.11)

![]()

Where:

![]() CSA

A23.3-14 (8.4.2)

CSA

A23.3-14 (8.4.2)

![]() CSA

A23.3-14 (8.4.3(a))

CSA

A23.3-14 (8.4.3(a))

![]() CSA

A23.3-14 (Equation 10.9)

CSA

A23.3-14 (Equation 10.9)

![]()

![]()

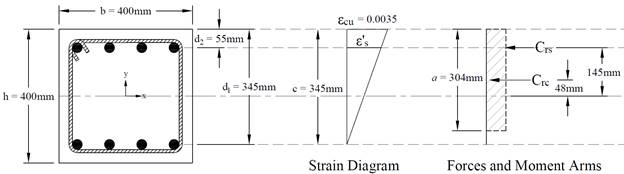

Figure 3 – Strains, Forces, and Moment Arms (εt = fs = 0)

Strain εs is zero in the extreme layer of tension steel. This case is considered when calculating an interaction diagram because it marks the change from compression lap splices being allowed on all longitudinal bars, to the more severe requirement of tensile lap splices. CSA A23.3-14 (12.15 and 16)

![]()

Where c is depth of the neutral axis measured from the compression edge of the column section.

CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

Where:

a = Depth of equivalent rectangular stress block CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (Equation 10.2)

CSA A23.3-14 (Equation 10.2)

![]()

![]() CSA

A23.3-14 (8.4.2)

CSA

A23.3-14 (8.4.2)

![]() CSA

A23.3-14 (8.4.3(a))

CSA

A23.3-14 (8.4.3(a))

![]() CSA

A23.3-14 (10.1.3)

CSA

A23.3-14 (10.1.3)

![]()

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

![]()

![]()

![]()

The area of the reinforcement in this layer has been included in the area (ab) used to compute Cc. As a result, it is necessary to subtract α1ϕcfc’ from ϕsfs’ before computing Crs:

![]()

![]()

![]()

![]()

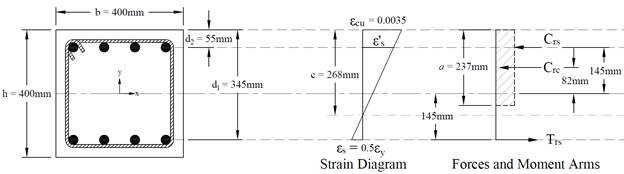

Figure 4 – Strains, Forces, and Moment Arms (fs = - 0.5 fy)

![]()

![]()

![]() CSA

A23.3-14 (8.4.2)

CSA

A23.3-14 (8.4.2)

![]() CSA

A23.3-14 (8.4.3(a))

CSA

A23.3-14 (8.4.3(a))

![]() CSA

A23.3-14 (10.1.3)

CSA

A23.3-14 (10.1.3)

![]()

Where c is depth of the neutral axis measured from the compression edge of the column section.

CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

Where:

a = Depth of equivalent rectangular stress block CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (Equation 10.2)

CSA A23.3-14 (Equation 10.2)

![]()

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

![]()

![]()

![]()

![]()

The area of the reinforcement in this layer has been included in the area (ab) used to compute Cc. As a result, it is necessary to subtract α1ϕcfc’ from ϕsfs’ before computing Crs:

![]()

![]()

![]()

![]()

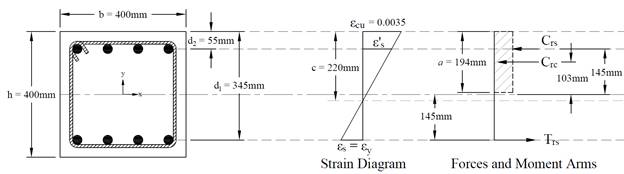

Figure 5 – Strains, Forces, and Moment Arms (fs = - fy)

This strain distribution is called the balanced failure case and the compression-controlled strain limit. It marks the change from compression failures originating by crushing of the compression surface of the section, to tension failures initiated by yield of longitudinal reinforcement.

![]()

![]()

![]() CSA

A23.3-14 (8.4.2)

CSA

A23.3-14 (8.4.2)

![]() CSA

A23.3-14 (8.4.3(a))

CSA

A23.3-14 (8.4.3(a))

![]() CSA

A23.3-14 (10.1.3)

CSA

A23.3-14 (10.1.3)

![]()

Where c is depth of the neutral axis measured from the compression edge of the column section.

CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

Where:

a = Depth of equivalent rectangular stress block CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (Equation 10.2)

CSA A23.3-14 (Equation 10.2)

![]()

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

![]()

![]()

![]()

![]()

The area of the reinforcement in this layer has been included in the area (ab) used to compute Cc. As a result, it is necessary to subtract α1ϕcfc’ from ϕsfs’ before computing Crs:

![]()

![]()

![]()

![]()

Figure 6 – Strains, Forces, and Moment Arms (Pure Moment)

This corresponds to the case where the factored axial load resistance, Pr, is equal to zero. Iterative procedure is used to determine the factored moment resistance as follows:

![]()

Where c is depth of the neutral axis measured from the compression edge of the column section.

CSA A23.3-14 (3.2)

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

Where:

![]() CSA A23.3-14 (Equation 10.2)

CSA A23.3-14 (Equation 10.2)

![]() CSA

A23.3-14 (10.1.3)

CSA

A23.3-14 (10.1.3)

![]()

![]()

![]() CSA

A23.3-14 (8.4.2)

CSA

A23.3-14 (8.4.2)

![]() CSA

A23.3-14 (8.4.3(a))

CSA

A23.3-14 (8.4.3(a))

![]()

![]() CSA A23.3-14 (10.1.7)

CSA A23.3-14 (10.1.7)

![]()

![]()

![]()

![]()

The area of the reinforcement in this layer has been included in the area (ab) used to compute Cc. As a result, it is necessary to subtract α1ϕcfc’ from ϕsfs’ before computing Crs:

![]()

![]()

The assumption that c = 78.55 mm is correct

![]()

![]()

The final loading case to be considered is concentric axial tension. The strength under pure axial tension is computed by assuming that the section is completely cracked through and subjected to a uniform strain greater than or equal to the yield strain in tension. The strength under such a loading is equal to the yield strength of the reinforcement in tension.

![]()

Since the section is symmetrical

![]()

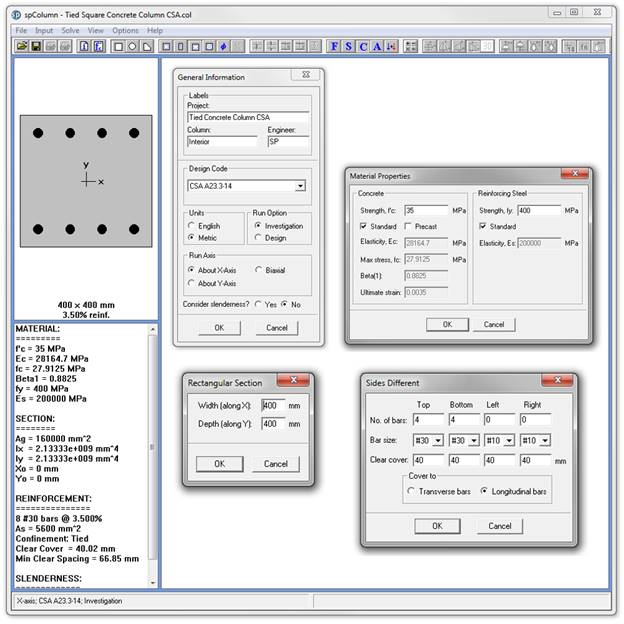

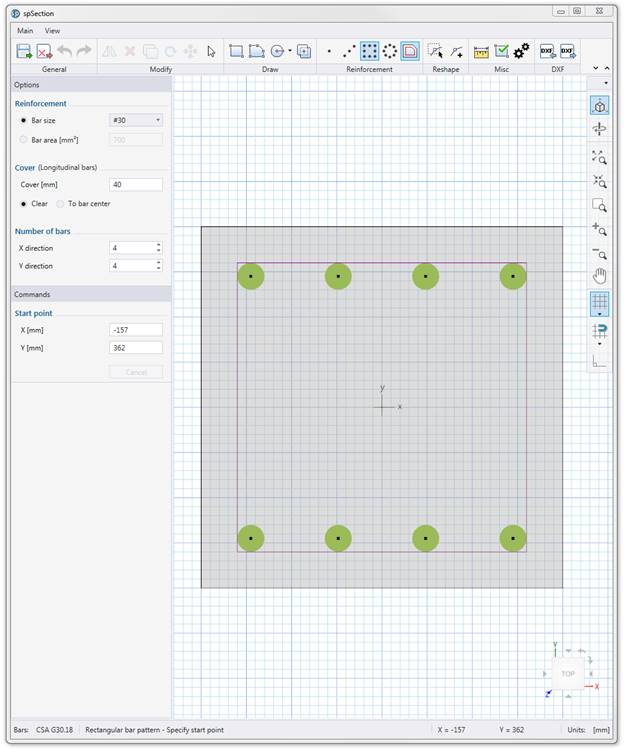

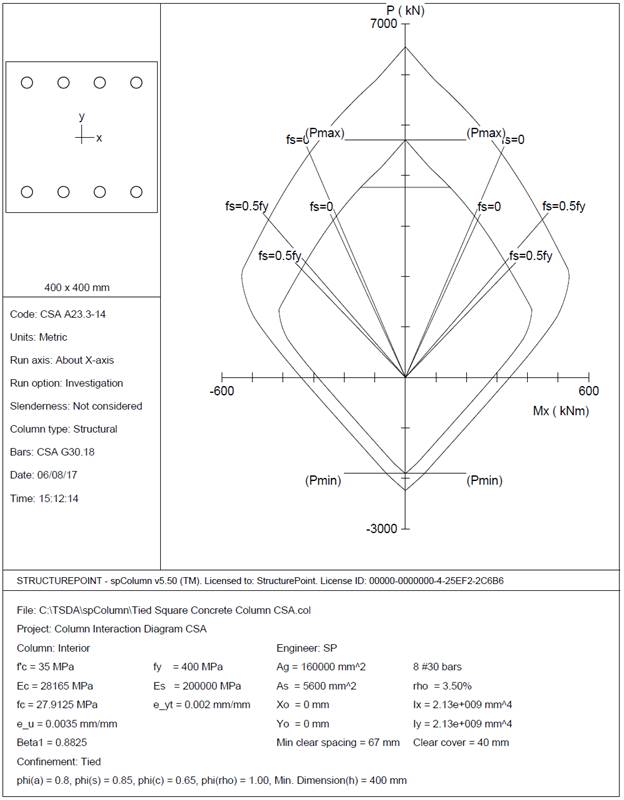

spColumn program performs the analysis of the reinforced concrete section conforming to the provisions of the Strength Design Method and Unified Design Provisions with all conditions of strength satisfying the applicable conditions of equilibrium and strain compatibility. For this column section, we ran in investigation mode with control points using the CSA A23.3-14. In lieu of using program shortcuts, spSection (Figure 9) was used to place the reinforcement and define the cover to illustrate handling of irregular shapes and unusual bar arrangement.

Figure 7 – Generating spColumn Model

Figure 8 – spColumn Model Editor (spSection)

Figure 9 – Column Section Interaction Diagram about the X-Axis (spColumn)

|

Table 1 - Comparison of Results |

||||||

|

Support |

Pr, kN |

Mr, kN.m |

||||

|

Hand |

Reference* ** |

Hand |

Reference* ** |

|||

|

Max compression |

4705 |

4490 |

4705 |

0 |

0 |

0 |

|

Allowable compression |

3764 |

3592 |

3764 |

--- |

--- |

--- |

|

fs = 0.0 |

3111 |

2945 |

3111 |

236 |

229 |

236 |

|

fs = 0.5 fy |

2144 |

2015 |

2144 |

340 |

330 |

340 |

|

Balanced point |

1355 |

1253 |

1355 |

414 |

403 |

414 |

|

Pure bending |

0 |

0 |

0 |

286 |

285 |

286 |

|

Max tension |

1904 |

1904 |

1904 |

0 |

0 |

0 |

|

* Reinforced Concrete Mechanic and Design, 1st Canadian Edition, James MacGregor and Fred Bartlett – Example 11-1 ** The reference used CSA A23.3-94 where the resistance factor for concrete (ϕc) is 0.60. The hand calculation and spColumn used CSA A23.3-14 where the resistance factor for concrete (ϕc) is 0.65. (Check Column Interaction Diagram Using CSA A23.3-94 Example) |

||||||

The analysis of the reinforced concrete section performed by spColumn conforms to the provisions of the Strength Design Method and Unified Design Provisions with all conditions of strength satisfying the applicable conditions of equilibrium and strain compatibility.

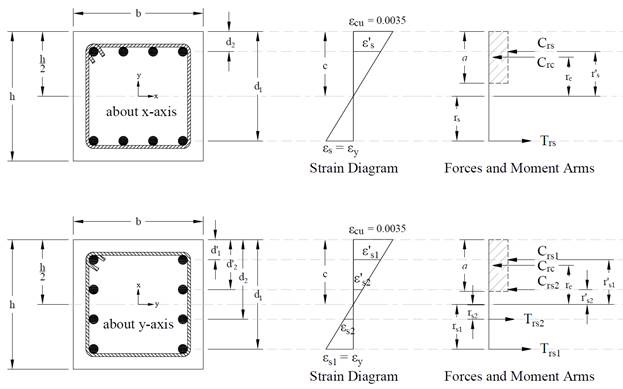

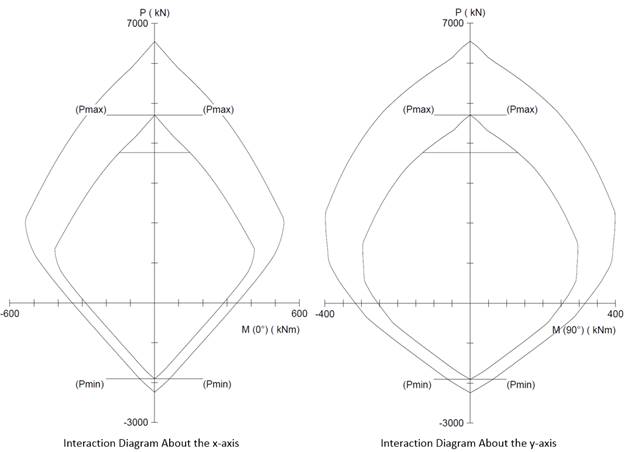

In the calculation shown above a P-M interaction diagram was generated with moments about the X-Axis (Uniaxial bending). Since the reinforcement in the section is not symmetrical, a different P-M interaction diagram is needed for the other orthogonal direction about the Y-Axis (See the following Figure for the case where fs = fy).

Figure 10 – Strains, Forces, and Moment Arms (fs = - fy Moments About x- and y-axis)

When running about the Y-Axis, we have 2 bars in 4 layers instead of 4 bars in just 2 layers (about X-Axis) resulting in a completely different interaction diagram as shown in the following Figure.

Figure 11 – Comparison of Column Interaction Diagrams about X-Axis and Y-Axis (spColumn)

Further differences in the interaction diagram in both directions can result if the column cross section geometry is irregular.

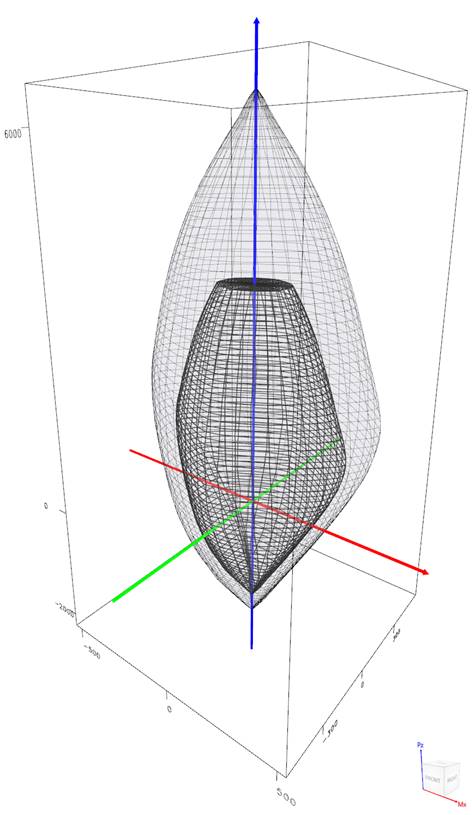

In most building design calculations, such as the examples shown for flat plate or flat slab concrete floor systems, all building columns are subjected to Mx and My due to lateral forces and unbalanced moments from both directions of analysis. This requires an evaluation of the column P-M interaction diagram in two directions simultaneously (biaxial bending).

StucturePoint’s spColumn program can also evaluate column sections in biaxial mode to produce the results shown in the following Figure for the column section in this example.

Figure 12 – Nominal & Design Interaction Diagram in Two Directions (Biaxial) (spColumn)