Code

Building Code Requirements

for Structural Concrete (ACI 318-14) and Commentary (ACI 318R-14)

Minimum Design Loads for

Buildings and Other Structures (ASCE/SEI 7-10)

International Code Council,

2012 International Building Code, Washington, D.C., 2012

References

Notes on ACI 318-11 Building

Code Requirements for Structural Concrete, Twelfth Edition, 2013 Portland

Cement Association.

Concrete Floor Systems

(Guide to Estimating and Economizing), Second Edition, 2002 David A. Fanella

Simplified Design of

Reinforced Concrete Buildings, Fourth Edition, 2011 Mahmoud E. Kamara and

Lawrence C. Novak

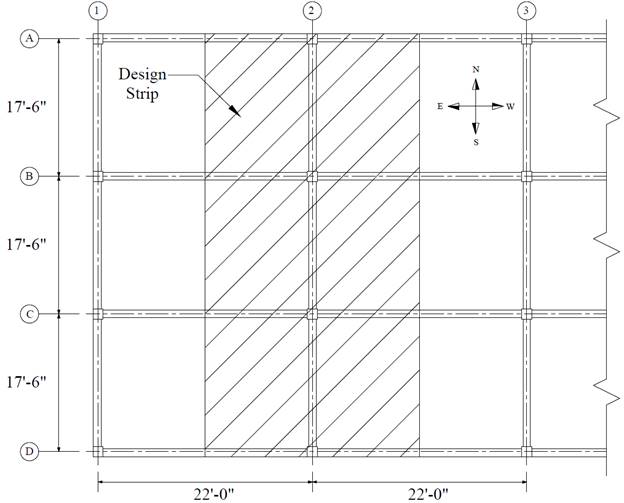

Design Data

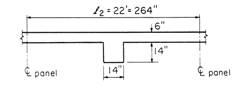

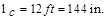

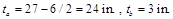

Floor-to-Floor Height = 12

ft (provided by architectural drawings)

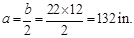

Columns = 18 x 18 in.

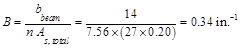

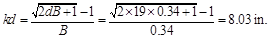

Interior beams = 14 x 20 in.

Edge beams = 14 x 27 in.

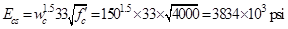

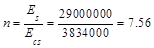

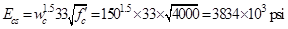

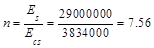

wc = 150 pcf

fc’ =

4,000 psi

fy = 60,000 psi

Live load, Lo

= 100 psf (Office building) ASCE/SEI

7-10 (Table 4-1)

Solution

Control of deflections. ACI

318-14 (8.3.1.2)

In lieu of detailed calculation for deflections, ACI 318 Code

gives minimum thickness for two-way slab with beams spanning between supports

on all sides in Table 8.3.1.2.

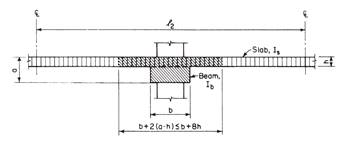

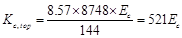

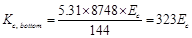

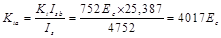

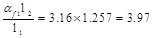

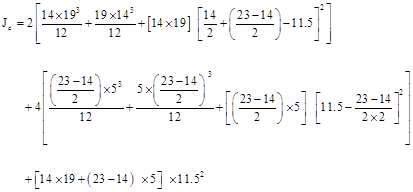

Beam-to-slab flexural stiffness

(relative stiffness) ratio (αf) is computed as follows:

ACI

318-14 (8.10.2.7b)

ACI

318-14 (8.10.2.7b)

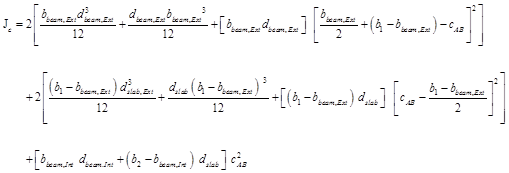

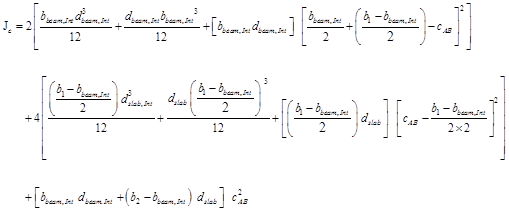

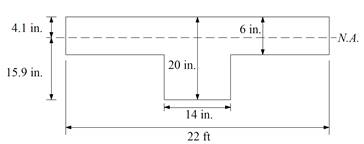

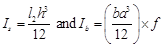

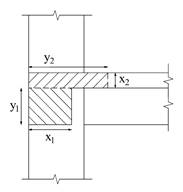

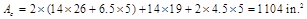

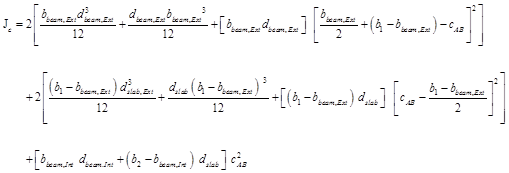

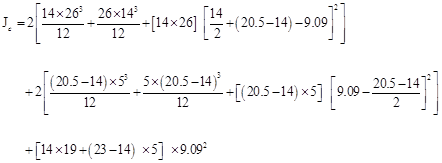

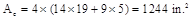

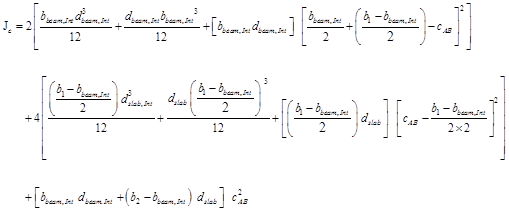

The moment of inertia for the

effective beam and slab sections can be calculated as follows:

Then,

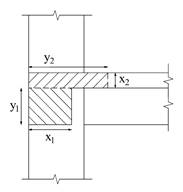

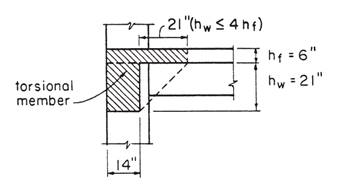

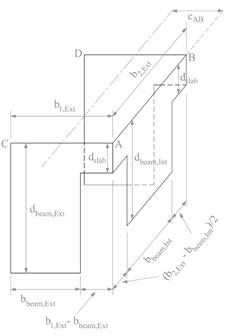

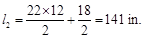

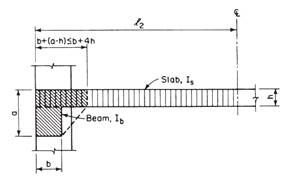

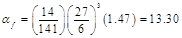

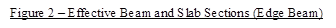

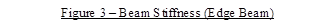

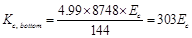

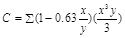

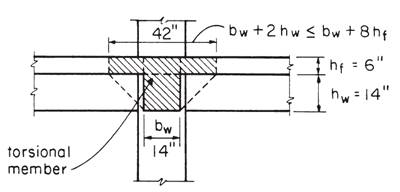

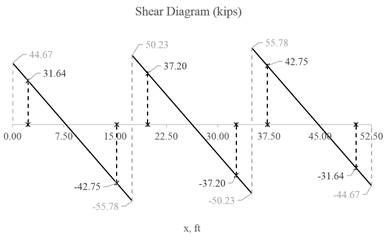

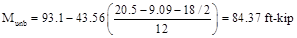

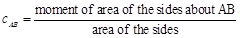

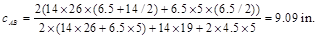

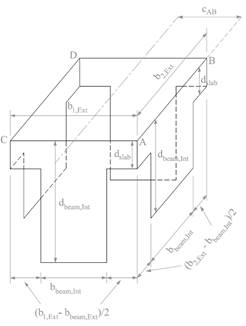

For Edge Beams:

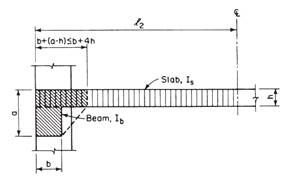

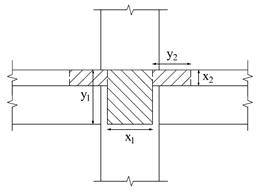

The effective beam and slab sections for the computation of

stiffness ratio for edge beam is shown in Figure 2.

For North-South Edge Beam:

For East-West

Edge Beam:

For East-West

Edge Beam:

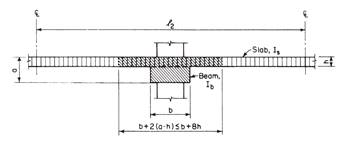

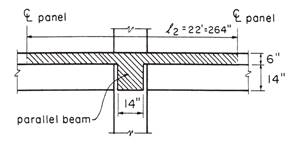

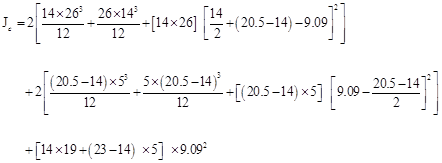

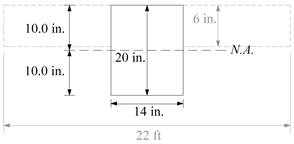

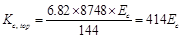

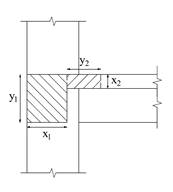

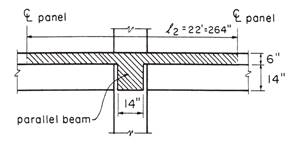

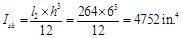

For interior Beams:

The effective beam and slab sections for the computation of

stiffness ratio for interior beam is shown in Figure 4.

For North-South Interior Beam:

For East-West

Interior Beam:

For East-West

Interior Beam:

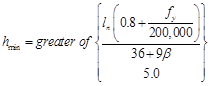

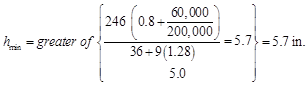

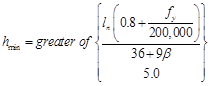

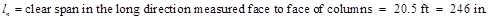

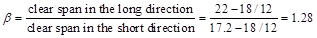

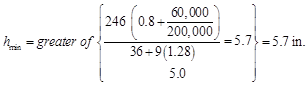

Since αf > 2.0 for

all beams, the minimum slab thickness is given by:

ACI

318-14 (8.3.1.2)

ACI

318-14 (8.3.1.2)

Where:

Use 6 in. slab thickness.

ACI 318 states that a slab system

shall be designed by any procedure satisfying equilibrium and geometric

compatibility, provided that strength and serviceability criteria are

satisfied. Distinction of two-systems from one-way systems is given by ACI

318-14 (R8.10.2.3 & R8.3.1.2).

ACI 318 permits the use of Direct

Design Method (DDM) and Equivalent Frame Method (EFM) for the gravity load

analysis of orthogonal frames and is applicable to flat plates, flat slabs, and

slabs with beams. The following sections outline the solution per EFM and spSlab software. The solution per DDM can

be found in the “Two-Way Plate Concrete Floor System Design” example.

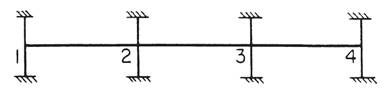

EFM is the most comprehensive and

detailed procedure provided by the ACI 318 for the analysis and design of

two-way slab systems where the structure is modeled by a series of equivalent

frames (interior and exterior) on column lines taken longitudinally and

transversely through the building.

The equivalent frame consists of three

parts:

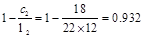

1) Horizontal slab-beam strip, including

any beams spanning in the direction of the frame. Different values of moment of

inertia along the axis of slab-beams should be taken into account where the

gross moment of inertia at any cross section outside of joints or column

capitals shall be taken, and the moment of inertia of the slab-beam at the

face of the column, bracket or capital divide by the quantity (1-c2/l2)2

shall be assumed for the calculation of the moment of inertia of slab-beams

from the center of the column to the face of the column, bracket or capital. ACI

318-14 (8.11.3)

2) Columns or other vertical supporting

members, extending above and below the slab. Different values of moment of

inertia along the axis of columns should be taken into account where the moment

of inertia of columns from top and bottom of the slab-beam at a joint shall be

assumed to be infinite, and the gross cross section of the concrete is

permitted to be used to determine the moment of inertia of columns at any cross

section outside of joints or column capitals. ACI

318-14 (8.11.4)

3) Elements of the structure (Torsional

members) that provide moment transfer between the horizontal and vertical

members. These elements shall be assumed to have a constant cross section

throughout their length consisting of the greatest of the following: (1)

portion of slab having a width equal to that of the column, bracket, or capital

in the direction of the span for which moments are being determined, (2)

portion of slab specified in (1) plus that part of the transverse beam above

and below the slab for monolithic or fully composite construction, (3) the

transverse beam includes that portion of slab on each side of the beam

extending a distance equal to the projection of the beam above or below the

slab, whichever is greater, but not greater than four times the slab thickness. ACI

318-14 (8.11.5)

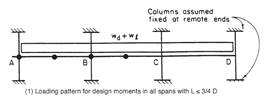

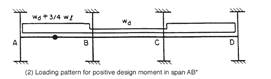

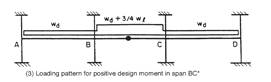

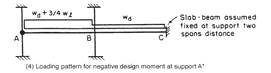

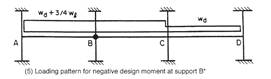

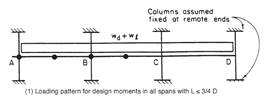

In

EFM, live load shall be arranged in accordance with 6.4.3 which requires slab

systems to be analyzed and designed for the most demanding set of forces

established by investigating the effects of live load placed in various

critical patterns. ACI 318-14 (8.11.1.2 & 6.4.3)

Complete

analysis must include representative interior and exterior equivalent frames in

both the longitudinal and transverse directions of the floor. ACI 318-14 (8.11.2.1)

Panels shall

be rectangular, with a ratio of longer to shorter panel dimensions, measured

center-to-center of supports, not to exceed 2. ACI 318-14 (8.10.2.3)

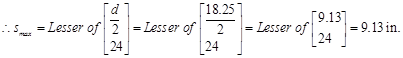

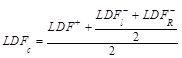

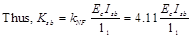

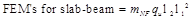

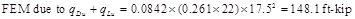

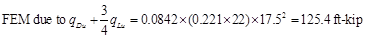

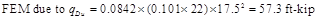

Determine moment distribution factors and fixed-end

moments for the equivalent frame members. The moment distribution procedure

will be used to analyze the equivalent frame. Stiffness factors  , carry over factors COF, and fixed-end moment factors

FEM for the slab-beams and column members are determined using the design aids tables

at Appendix 20A of PCA Notes on ACI 318-11. These

calculations are shown below.

, carry over factors COF, and fixed-end moment factors

FEM for the slab-beams and column members are determined using the design aids tables

at Appendix 20A of PCA Notes on ACI 318-11. These

calculations are shown below.

a.

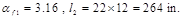

Flexural

stiffness of slab-beams at both ends, Ksb.

PCA Notes on ACI 318-11 (Table A1)

PCA Notes on ACI 318-11 (Table A1)

PCA Notes on ACI 318-11 (Table A1)

PCA Notes on ACI 318-11 (Table A1)

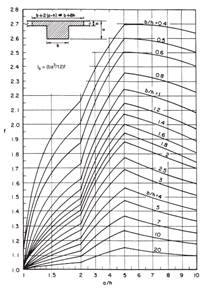

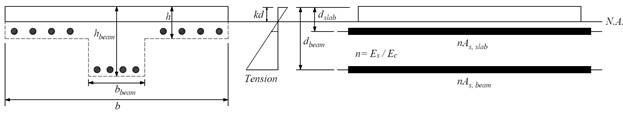

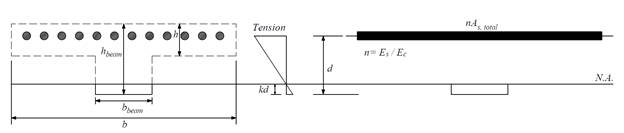

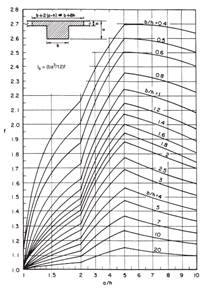

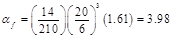

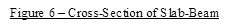

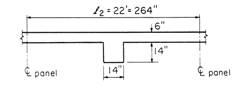

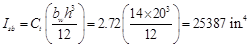

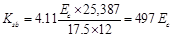

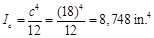

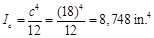

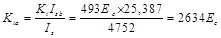

Where Isb

is the moment of inertia of slab-beam section shown in Figure 6 and can be

computed with the aid of Figure 7 as follows:

Where Isb

is the moment of inertia of slab-beam section shown in Figure 6 and can be

computed with the aid of Figure 7 as follows:

Carry-over factor COF = 0.507 PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

Figure 7 –

Coefficient Ct for Gross Moment of Inertia of Flanged Sections

b.

Flexural

stiffness of column members at both ends, Kc.

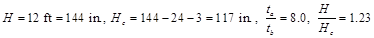

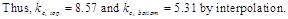

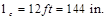

Referring to Table

A7, Appendix 20A:

For Interior

Columns:

PCA

Notes on ACI 318-11 (Table A7)

PCA

Notes on ACI 318-11 (Table A7)

For Exterior Columns:

PCA

Notes on ACI 318-11 (Table A7)

PCA

Notes on ACI 318-11 (Table A7)

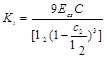

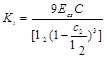

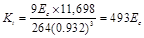

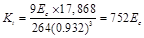

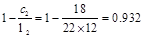

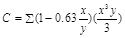

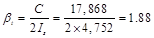

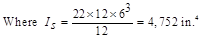

c.

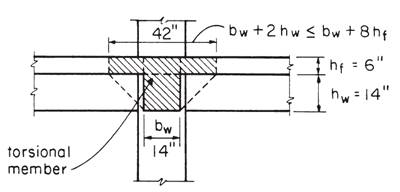

Torsional stiffness

of torsional members, Kt.

ACI 318-14 (R.8.11.5)

ACI 318-14 (R.8.11.5)

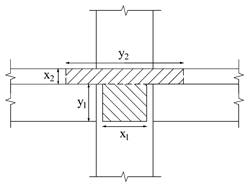

For

Interior Columns:

Where:

ACI 318-14 (Eq. 8.10.5.2b)

ACI 318-14 (Eq. 8.10.5.2b)

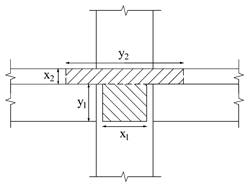

|

x1

= 14 in

|

x2

= 6 in

|

x1

= 14 in

|

x2

= 6 in

|

|

y1

= 14 in

|

y2

= 42 in

|

y1

= 20 in

|

y2

= 14 in

|

|

C1

= 4738

|

C2

= 2,752

|

C1

= 10,226

|

C2

= 736

|

|

∑C

= 4738 + 2,752 = 7,490 in4

|

∑C

= 10,226 + 736 x 2 = 11,698 in4

|

|

|

|

Figure 8 –

Attached Torsional Member at Interior Column

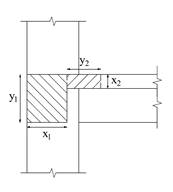

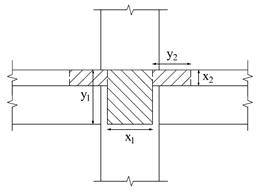

For Exterior

Columns:

Where:

ACI 318-14 (Eq. 8.10.5.2b)

ACI 318-14 (Eq. 8.10.5.2b)

|

x1

= 14 in

|

x2

= 6 in

|

x1

= 14 in

|

x2

= 6 in

|

|

y1

= 21 in

|

y2

= 35 in

|

y1

= 27 in

|

y2

= 21 in

|

|

C1

= 11,141

|

C2

= 2,248

|

C1

= 16,628

|

C2

= 1,240

|

|

∑C

= 11,141 + 2,248 = 13,389 in4

|

∑C

= 16,628 + 1,240 = 17,868 in4

|

|

|

|

Figure 9 –

Attached Torsional Member at Exterior Column

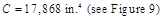

d. Increased torsional stiffness due to

parallel beams, Kta.

For Interior Columns:

Where:

For Exterior Columns:

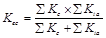

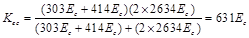

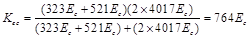

e.

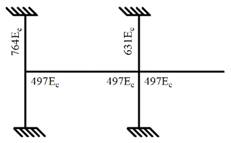

Equivalent column

stiffness Kec.

Where ∑ Kta is for two torsional members one on each side of the column, and ∑ Kc is for the upper and lower columns at the slab-beam joint of an

intermediate floor.

Where ∑ Kta is for two torsional members one on each side of the column, and ∑ Kc is for the upper and lower columns at the slab-beam joint of an

intermediate floor.

For Interior Columns:

For Exterior Columns:

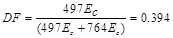

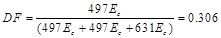

f. Slab-beam joint distribution factors,

DF.

At exterior joint,

At

interior joint,

COF for slab-beam =0.507

COF for slab-beam =0.507

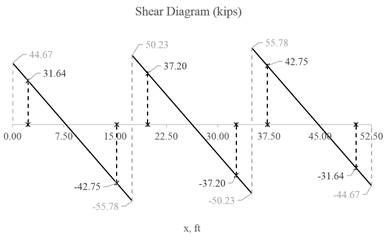

Determine

negative and positive moments for the slab-beams using the moment distribution

method.

With

an unfactored live-to-dead load ratio:

The frame will be analyzed

for five loading conditions with pattern loading and partial live load as

allowed by ACI 318-14 (6.4.3.3).

a.

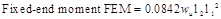

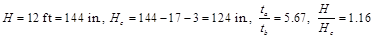

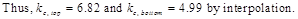

Factored load and

Fixed-End Moments (FEM’s).

Where (9.3 psf = (14 x 14) /

144 x 150 / 22 is the weight of beam stem per foot divided by l2)

PCA Notes on ACI 318-11 (Table A1)

PCA Notes on ACI 318-11 (Table A1)

b. Moment distribution.

Moment distribution for the five

loading conditions is shown in Table 1. Counter-clockwise rotational moments

acting on member ends are taken as positive. Positive span moments are

determined from the following equation:

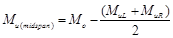

Where

Mo is the moment at the midspan for a simple beam.

When

the end moments are not equal, the maximum moment in the span does not occur at

the midspan, but its value is close to that midspan for this example.

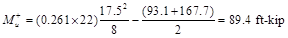

Positive

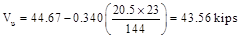

moment in span 1-2 for loading (1):

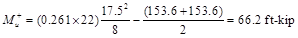

Positive moment span 2-3 for loading

(1):

|

Table 1 – Moment

Distribution for Partial Frame (Transverse Direction)

|

|

Joint

|

1

|

2

|

3

|

4

|

|

|

Member

|

1-2

|

2-1

|

2-3

|

3-2

|

3-4

|

4-3

|

|

DF

|

0.394

|

0.306

|

0.306

|

0.306

|

0.306

|

0.394

|

|

COF

|

0.507

|

0.507

|

0.507

|

0.507

|

0.507

|

0.507

|

|

Loading (1) All

spans loaded with full factored live load

|

|

FEM

|

148.1

|

-148.1

|

148.1

|

-148.1

|

148.1

|

-148.1

|

|

|

Dist

|

-58.4

|

0

|

0

|

0

|

0

|

58.4

|

|

CO

|

0

|

-29.6

|

0

|

0

|

29.6

|

0

|

|

Dist

|

0

|

9.1

|

9.1

|

-9.1

|

-9.1

|

0

|

|

CO

|

4.6

|

0

|

-4.6

|

4.6

|

0

|

-4.6

|

|

Dist

|

-1.8

|

1.4

|

1.4

|

-1.4

|

-1.4

|

1.8

|

|

CO

|

0.7

|

-0.9

|

-0.7

|

0.7

|

0.9

|

-0.7

|

|

Dist

|

-0.3

|

0.5

|

0.5

|

-0.5

|

-0.5

|

0.3

|

|

CO

|

0.3

|

-0.1

|

-0.3

|

0.3

|

0.1

|

-0.3

|

|

Dist

|

-0.1

|

0.1

|

0.1

|

-0.1

|

-0.1

|

0.1

|

|

M

|

93.1

|

-167.6

|

153.6

|

-153.6

|

167.6

|

-93.1

|

|

Midspan M

|

89.5

|

66.2

|

89.5

|

|

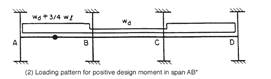

Loading (2)

First and third spans loaded with 3/4 factored live load

|

|

FEM

|

125.4

|

-125.4

|

57.3

|

-57.3

|

125.4

|

-125.4

|

|

|

Dist

|

-49.4

|

20.8

|

20.8

|

-20.8

|

-20.8

|

49.4

|

|

CO

|

10.6

|

-25.1

|

-10.6

|

10.6

|

25.1

|

-10.6

|

|

Dist

|

-4.2

|

10.9

|

10.9

|

-10.9

|

-10.9

|

4.2

|

|

CO

|

5.5

|

-2.1

|

-5.5

|

5.5

|

2.1

|

-5.5

|

|

Dist

|

-2.2

|

2.3

|

2.3

|

-2.3

|

-2.3

|

2.2

|

|

CO

|

1.2

|

-1.1

|

-1.2

|

1.2

|

1.1

|

-1.2

|

|

Dist

|

-0.5

|

0.7

|

0.7

|

-0.7

|

-0.7

|

0.5

|

|

CO

|

0.4

|

-0.2

|

-0.4

|

0.4

|

0.2

|

-0.4

|

|

Dist

|

-0.1

|

0.2

|

0.2

|

-0.2

|

-0.2

|

0.1

|

|

M

|

86.7

|

-119

|

74.5

|

-74.5

|

119

|

-86.7

|

|

Midspan M

|

83.3

|

10.6

|

83.3

|

|

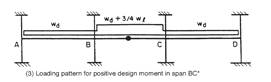

Loading (3)

Center span loaded with 3/4 factored live load

|

|

FEM

|

57.3

|

-57.3

|

125.4

|

-125.4

|

57.3

|

-57.3

|

|

|

Dist

|

-22.6

|

-20.8

|

-20.8

|

20.8

|

20.8

|

22.6

|

|

CO

|

-10.6

|

-11.4

|

10.6

|

-10.6

|

11.4

|

10.6

|

|

Dist

|

4.2

|

0.3

|

0.3

|

-0.3

|

-0.3

|

-4.2

|

|

CO

|

0.1

|

2.1

|

-0.1

|

0.1

|

-2.1

|

-0.1

|

|

Dist

|

-0.1

|

-0.6

|

-0.6

|

0.6

|

0.6

|

0.1

|

|

CO

|

-0.3

|

0

|

0.3

|

-0.3

|

0

|

0.3

|

|

Dist

|

0.1

|

-0.1

|

-0.1

|

0.1

|

0.1

|

-0.1

|

|

CO

|

0

|

0.1

|

0

|

0

|

-0.1

|

0

|

|

Dist

|

0

|

0

|

0

|

0

|

0

|

0

|

|

M

|

28.1

|

-87.7

|

115

|

-115

|

87.7

|

-28.1

|

|

Midspan M

|

27.2

|

71.3

|

27.2

|

|

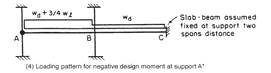

Loading (4)

First span loaded with 3/4 factored live load and beam-slab assumed fixed at

support two spans away

|

|

FEM

|

125.4

|

-125.4

|

57.3

|

-57.3

|

|

|

|

Dist

|

-49.4

|

20.8

|

20.8

|

0

|

|

CO

|

10.6

|

-25

|

0

|

10.6

|

|

Dist

|

-4.2

|

7.7

|

7.7

|

0

|

|

CO

|

3.9

|

-2.1

|

0

|

3.9

|

|

Dist

|

-1.5

|

0.6

|

0.6

|

0

|

|

CO

|

0.3

|

-0.8

|

0

|

0.3

|

|

Dist

|

-0.1

|

0.2

|

0.2

|

0

|

|

CO

|

0.1

|

-0.1

|

0

|

0.1

|

|

Dist

|

0

|

0

|

0

|

0

|

|

M

|

85.1

|

-124.1

|

86.6

|

-42.4

|

|

Midspan M

|

81.5

|

20.6

|

|

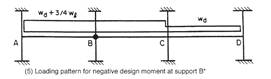

Loading (5)

First and second spans loaded with 3/4 factored live load

|

|

FEM

|

125.4

|

-125.4

|

125.4

|

-125.4

|

57.3

|

-57.3

|

|

|

Dist

|

-49.4

|

0.0

|

0.0

|

20.8

|

20.8

|

22.6

|

|

CO

|

0.0

|

-25.1

|

10.6

|

0.0

|

11.4

|

10.6

|

|

Dist

|

0.0

|

4.4

|

4.4

|

-3.5

|

-3.5

|

-4.2

|

|

CO

|

2.2

|

0.0

|

-1.8

|

2.2

|

-2.1

|

-1.8

|

|

Dist

|

-0.9

|

0.5

|

0.5

|

0.0

|

0.0

|

0.7

|

|

CO

|

0.3

|

-0.4

|

0.0

|

0.3

|

0.4

|

0.0

|

|

Dist

|

-0.1

|

0.1

|

0.1

|

-0.2

|

-0.2

|

0.0

|

|

CO

|

0.1

|

-0.1

|

-0.1

|

0.1

|

0.0

|

-0.1

|

|

Dist

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

|

M

|

77.6

|

-146.0

|

139.1

|

-105.7

|

84.1

|

-29.5

|

|

Midspan M

|

74.3

|

63.7

|

28.3

|

|

|

|

|

Max M-

|

93.1

|

-167.7

|

153.6

|

-153.6

|

167.7

|

-93.1

|

|

Max M+

|

89.4

|

71.3

|

89.4

|

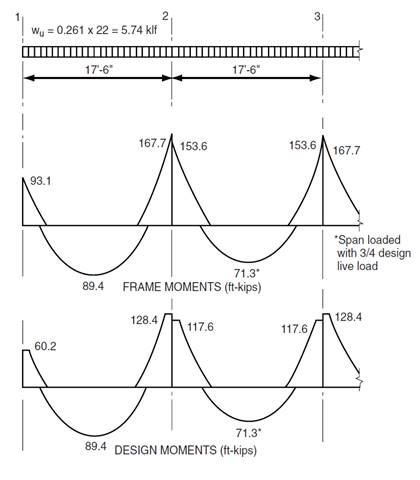

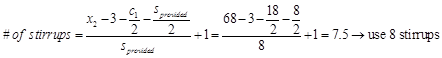

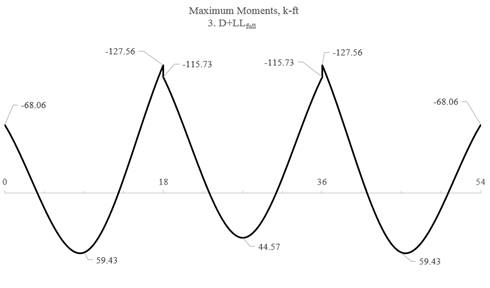

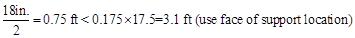

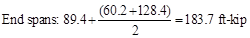

Positive and negative factored

moments for the slab system in the direction of analysis are plotted in Figure

13. The negative design moments are taken at the faces of rectilinear supports

but not at distances greater than  from the centers of supports. ACI

318-14 (8.11.6.1)

from the centers of supports. ACI

318-14 (8.11.6.1)

Figure 13 – Positive and Negative Design Moments for

Slab-Beam (All Spans Loaded with Full Factored Live Load Except as Noted)

a. Check whether the moments calculated

above can take advantage of the reduction permitted by ACI 318-14 (8.11.6.5):

Slab systems within the limitations

of ACI 318-14 (8.10.2) may have the resulting reduced in

such proportion that the numerical sum of the positive and average negative

moments not be greater than the total static moment Mo given

by Equation 8.10.3.2 in the ACI 318-14:

ACI 318-14 (8.11.6.5)

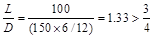

Check Applicability of Direct Design

Method:

1.

There is a

minimum of three continuous spans in each direction ACI

318-14 (8.10.2.1)

2.

Successive span

lengths are equal ACI

318-14 (8.10.2.2)

3.

Long-to-Short

ratio is 22/17.5 = 1.26 < 2.0 ACI

318-14 (8.10.2.3)

4.

Column are not

offset ACI

318-14 (8.10.2.4)

5.

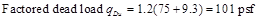

Loads are gravity

and uniformly distributed with service live-to-dead ratio of 1.33 < 2.0

ACI

318-14 (8.10.2.5 and 6)

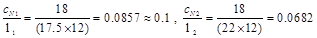

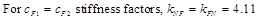

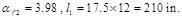

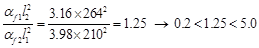

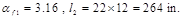

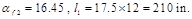

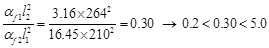

6. Check relative stiffness for slab panel: ACI

318-14 (8.10.2.7)

Interior Panel:

O.K. ACI 318-14

(Eq. 8.10.2.7a)

O.K. ACI 318-14

(Eq. 8.10.2.7a)

Interior Panel:

O.K. ACI 318-14

(Eq. 8.10.2.7a)

O.K. ACI 318-14

(Eq. 8.10.2.7a)

All limitation of ACI

318-14 (8.10.2) are satisfied and the provisions of ACI

318-14 (8.11.6.5) may be applied:

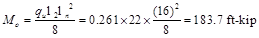

ACI

318-14 (Eq. 8.10.3.2)

ACI

318-14 (Eq. 8.10.3.2)

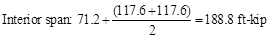

To

illustrate proper procedure, the interior span factored moments may be reduced

as follows:

Permissible

reduction = 183.7/188.8 = 0.973

Adjusted negative design

moment = 117.6 × 0.973 = 114.3 ft-kip

Adjusted positive design

moment = 71.2 × 0.973 = 69.3 ft-kip

Mo = 183.7 ft-kip

b. Distribute factored moments to column

and middle strips:

The negative and positive factored moments at critical

sections may be distributed to the column strip and the two half-middle strips

of the slab-beam according to the Direct Design Method (DDM) in 8.10, provided

that Eq. 8.10.2.7(a) is satisfied. ACI

318-14 (8.11.6.6)

Since the relative stiffness of beams are between 0.2

and 5.0 (see step 2.4.1.6), the moments can be distributed across slab-beams as

specified in ACI 318-14 (8.10.5 and 6) where:

Factored moments at critical

sections are summarized in Table 2.

|

Table 2 - Lateral

distribution of factored moments

|

|

Factored Moments

(ft-kips)

|

Column Strip

|

Moments in Two

Half-Middle Strips**

(ft-kips)

|

|

Percent*

|

Moment

(ft-kips)

|

Beam Strip

Moment

(ft-kips)

|

Column Strip

Moment

(ft-kips)

|

|

End

Span

|

Exterior Negative

|

60.2

|

75

|

45.2

|

38.4

|

6.8

|

15

|

|

Positive

|

89.4

|

67

|

59.9

|

50.9

|

9.0

|

29.5

|

|

Interior Negative

|

128.4

|

67

|

86

|

73.1

|

12.9

|

42.4

|

|

Interior

Span

|

Negative

|

117.6

|

67

|

78.8

|

67.0

|

11.8

|

38.8

|

|

Positive

|

71.3

|

67

|

47.8

|

40.6

|

7.2

|

23.5

|

|

*Since α1l2/l1 >

1.0 beams must be proportioned to resist 85 percent of column strip per ACI

318-14 (8.10.5.7)

|

|

**That portion of the factored moment not resisted by the

column strip is assigned to the two half-middle strips

|

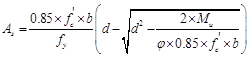

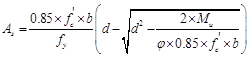

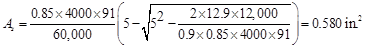

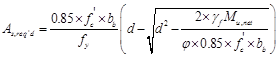

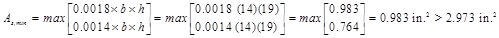

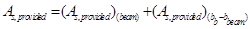

a. Determine flexural reinforcement required for strip

moments

The flexural reinforcement

calculation for the column strip of end span – interior negative location is

provided below:

Assume tension-controlled

section (φ = 0.9)

Column strip width, b

= (17.5 x 12) / 2 = 91 in.

Use average d = 6 –

0.75 – 0.5/2 = 5 in.

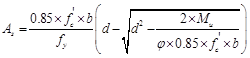

in2

in2

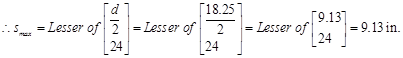

Maximum spacing  ACI

318-14 (8.7.2.2)

ACI

318-14 (8.7.2.2)

Provide 8 - #4 bars with As

= 1.60 in.2 and s =

91/8 = 11.37 in. ≤ smax

The

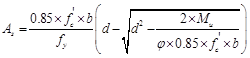

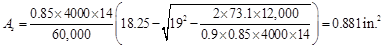

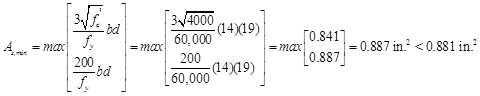

flexural reinforcement calculation for the beam strip of end span – interior

negative location is provided below:

Assume tension-controlled

section (φ = 0.9)

Beam strip width, b =

14 in.

Use average d = 20 –

0.75 – 0.5/2 = 19 in.

Provide 5 - #4 bars with As

= 1.00 in.2

All the values on Table 3 are

calculated based on the procedure outlined above.

|

Table 3 -

Required Slab Reinforcement for Flexure [Equivalent Frame Method (EFM)]

|

|

|

Span

Location

|

Mu

(ft-kip)

|

b *

(in.)

|

d **

(in.)

|

As Req’d

for flexure

(in.2)

|

Min As†

††

(in.2)

|

Reinforcement

Provided

|

As Prov.

for flexure

(in.2)

|

|

|

|

End Span

|

|

|

Beam Strip

|

Exterior Negative

|

38.4

|

14

|

19.00

|

0.456

|

0.608

|

4 - #4

|

0.8

|

|

|

Positive

|

50.9

|

14

|

18.25

|

0.634

|

0.852

|

5 - #4

|

1.0

|

|

|

Interior Negative

|

73.1

|

14

|

19.00

|

0.881

|

0.887

|

5 - #4

|

1.0

|

|

|

Column Strip

|

Exterior Negative

|

6.8

|

91

|

5.00

|

0.304

|

0.983

|

8 - #4

|

1.6

|

|

|

Positive

|

9.0

|

91

|

5.00

|

0.403

|

0.983

|

8 - #4

|

1.6

|

|

|

Interior Negative

|

12.9

|

91

|

5.00

|

0.580

|

0.983

|

8 - #4

|

1.6

|

|

|

Middle Strip

|

Exterior Negative

|

15.0

|

159

|

5.00

|

0.672

|

1.717

|

14 - #4

|

2.8

|

|

|

Positive

|

29.5

|

159

|

5.00

|

1.331

|

1.717

|

14 - #4

|

2.8

|

|

|

Interior Negative

|

42.4

|

159

|

5.00

|

1.926

|

1.717

|

14 - #4

|

2.8

|

|

|

Interior

Span

|

|

|

Beam Strip

|

Positive

|

40.6

|

14

|

18.25

|

0.503

|

0.671

|

4 - #4

|

0.8

|

|

|

Column Strip

|

Positive

|

7.2

|

91

|

5.00

|

0.322

|

0.983

|

8 - #4

|

1.6

|

|

|

Middle Strip

|

Positive

|

23.5

|

159

|

5.00

|

1.057

|

1.717

|

14 - #4

|

2.8

|

|

|

* Column strip width, b = (17.5 × 12)/2 - 14 = 91 in.

|

|

|

* Middle strip width, b = 22*12-(17.5*12)/2 = 159 in.

|

|

|

* Beam strip width, b = 14 in.

|

|

|

** Use average d = 6 – 0.75 – 0.5/2 = 5.00 in. for Column

and Middle strips

|

|

|

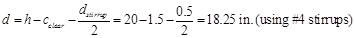

** Use average d = 20 - 1.5 - 0.5/2 = 18.25 in. for Beam

strip Positive moment regions

|

|

|

** Use average d = 20 - 0.75 - 0.5/2 = 19 in. for Beam strip

Negative moment regions

|

|

|

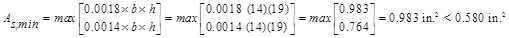

† Min. As = 0.0018 × b × h = 0.0108 × b for

Column and Middle

strips ACI 318-14

(7.6.1.1)

|

|

|

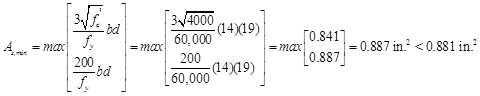

† Min. As = min (3(fc')^0.5/fy*b*d

, 200/fy*b*d) for Beam

strip ACI

318-14 (9.6.1.2)

|

|

|

†† Min. As = 1.333 × As Req'd if As provided

>= 1.333 × As Req'd for Beam strip ACI

318-14 (9.6.1.3)

|

|

|

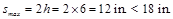

smax = 2 × h = 12 in. < 18

in.

ACI 318-14 (8.7.2.2)

|

|

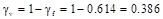

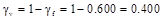

b.

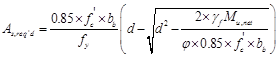

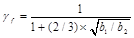

Calculate additional slab reinforcement at columns for moment transfer between slab

and column by flexure

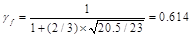

Portion of the unbalanced

moment transferred by flexure is γf x Mu

Where:

ACI 318-14 (8.4.2.3.2)

ACI 318-14 (8.4.2.3.2)

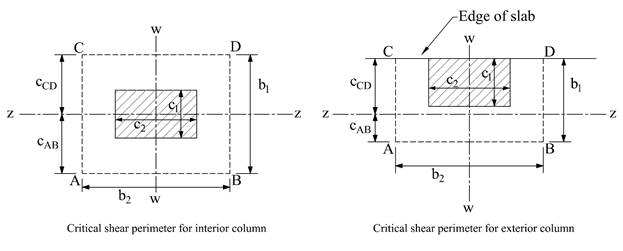

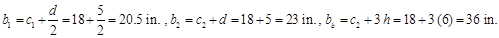

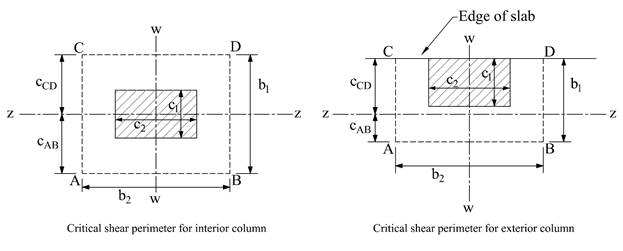

b1 = Dimension of the critical section bo

measured in the direction of the span for which

moments are determined in ACI 318, Chapter 8.

b2 = Dimension of the critical section bo

measured in the direction perpendicular to b1

in ACI 318, Chapter 8.

bo

= Perimeter of critical section for two-way

shear in slabs and footings.

ACI

318-14 (8.4.2.3.3)

ACI

318-14 (8.4.2.3.3)

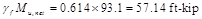

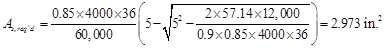

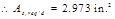

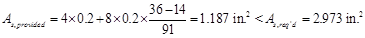

For Exterior Column:

Figure 14 – Critical Shear Perimeters for Columns

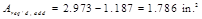

Additional slab reinforcement at the exterior column

is required.

Additional slab reinforcement at the exterior column

is required.

|

Table 4 -

Additional Slab Reinforcement at columns for moment transfer between slab and

column [Equivalent Frame Method (EFM)]

|

|

Span

Location

|

Effective

slab width, bb (in.)

|

d

(in.)

|

γf

|

Mu*

(ft-kip)

|

γf

Mu

(ft-kip)

|

As

req’d within bb (in.2)

|

As

prov. for

flexure

within bb (in.2)

|

Add’l Reinf.

|

|

End Span

|

|

Column Strip

|

Exterior

Negative

|

36

|

5

|

0.614

|

93.1

|

57.14

|

2.973

|

1.187

|

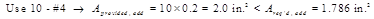

10-#4

|

|

Interior

Negative

|

36

|

5

|

0.600

|

44.5

|

26.70

|

1.265

|

1.387

|

-

|

|

*Mu is taken at the centerline

of the support in Equivalent Frame Method solution.

|

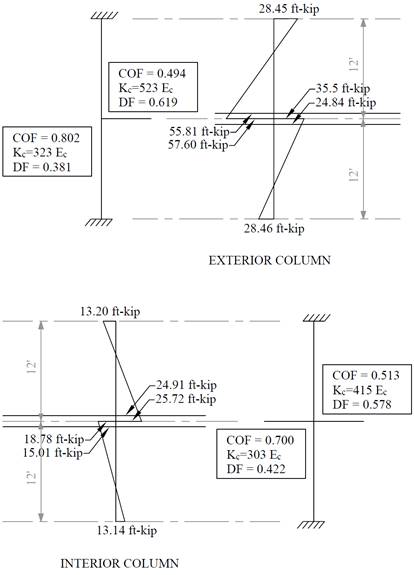

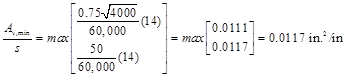

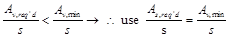

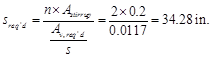

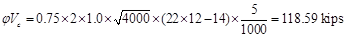

b. Determine

transverse reinforcement required for beam strip shear

The

transverse reinforcement calculation for the beam strip of end span – exterior

location is provided below.

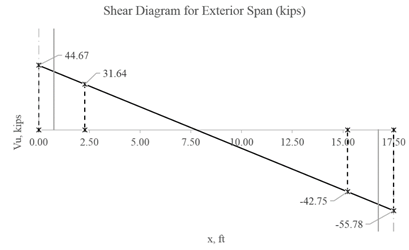

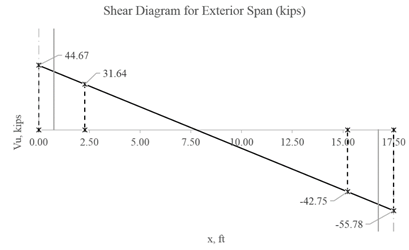

Figure 15 – Shear at critical sections for the end

span (at distance d from the face of the column)

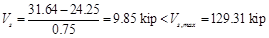

The required shear at a

distance d from the face of the supporting column Vu_d= 31.64

kips (Figure 15).

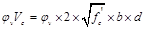

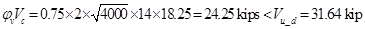

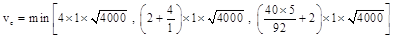

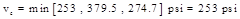

ACI

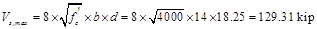

318-14 (22.5.5.1)

ACI

318-14 (22.5.5.1)

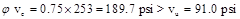

∴

Stirrups are required.

∴

Stirrups are required.

Distance from the column face

beyond which minimum reinforcement is required:

ACI

318-14 (22.5.10.1)

ACI

318-14 (22.5.10.1)

O.K.

O.K.

ACI 318-14 (22.5.10.1)

ACI 318-14 (22.5.10.1)

ACI

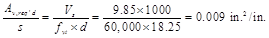

318-14 (22.5.10.5.3)

ACI

318-14 (22.5.10.5.3)

ACI

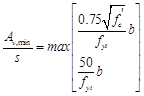

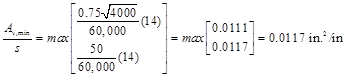

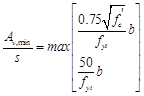

318-14 (9.6.3.3)

ACI

318-14 (9.6.3.3)

ACI 318-14 (9.7.6.2.2)

ACI 318-14 (9.7.6.2.2)

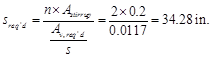

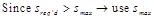

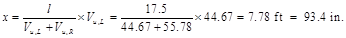

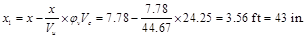

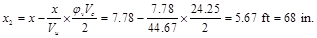

Select

sprovided = 8 in. #4 stirrups with first stirrup located at

distance 3 in. from the column face.

The

distance where the shear is zero is calculated as follows:

The

distance from support beyond which minimum reinforcement is required is

calculated as follows:

The

distance at which no shear reinforcement is required is calculated as follows:

All

the values on Table 5 are calculated based on the procedure outlined above.

|

Table 5 - Required Beam

Reinforcement for Shear

|

|

Span Location

|

Av,min/s

in2/in

|

Av,req'd/s

in2/in

|

sreq'd

in

|

smax

in

|

Reinforcement

Provided

|

|

End Span

|

|

Exterior

|

0.0117

|

0.0090

|

34.28

|

9.13

|

8 - #4 @ 8 in*

|

|

Interior

|

0.0117

|

0.0225

|

17.76

|

9.13

|

10 - #4 @ 8.6 in

|

|

Interior Span

|

|

Interior

|

0.0117

|

0.0158

|

25.37

|

9.13

|

9 - #4 @ 8.6 in

|

|

* Minimum

transverse reinforcement governs

|

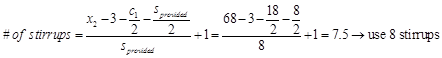

The

unbalanced moment from the slab-beams at the supports of the equivalent frame

are distributed to the actual columns above and below the slab-beam in

proportion to the relative stiffness of the actual columns. Referring to Fig.

9, the unbalanced moment at joints 1 and 2 are:

Joint

1 = +93.1 ft-kip

Joint

2 = -119 + 74.5 = -44.5 ft-kip

The

stiffness and carry-over factors of the actual columns and the distribution of

the unbalanced moments to the exterior and interior columns are shown in Fig 9.

Figure 16 - Column Moments (Unbalanced Moments from

Slab-Beam)

In summary:

Design moment in exterior

column = 55.81 ft-kip

Design

moment in interior column = 24.91 ft-kip

The

moments determined above are combined with the factored axial loads (for each

story) and factored moments in the transverse direction for design of column

sections. A detailed analysis to obtain the moment values at the face of

interior, exterior, and corner columns from the unbalanced moment values can be

found in the “Two-Way Flat Plate Concrete Floor Slab Design” example.

The design of

interior, edge, and corner columns is explained in the “Two-Way Flat Plate Concrete Floor Slab Design” example.

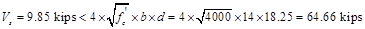

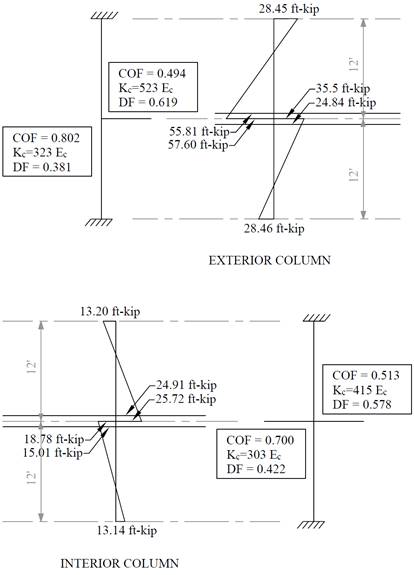

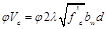

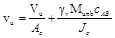

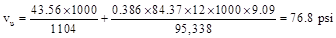

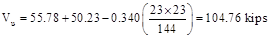

Shear strength of the slab in the vicinity

of columns/supports includes an evaluation of one-way shear (beam action) and

two-way shear (punching) in accordance with ACI 318 Chapter 22.

One-way shear is critical at

a distance d from the face of the column. Figure 17 shows the Vu at

the critical sections around each column. Since there is no shear

reinforcement, the design shear capacity of the section equals to the design

shear capacity of the concrete:

ACI 318-14 (Eq. 22.5.1.1)

ACI 318-14 (Eq. 22.5.1.1)

Where:

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

λ = 1 for normal weight concrete

Because φVc

> Vu at all the

critical sections, the slab is o.k. in one-way shear.

Figure 17 – One-way shear at critical sections (at

distance d from the face of the supporting column)

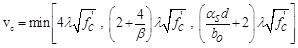

Two-way shear is critical on a rectangular section

located at dslab/2 away from the face of the column. The

factored shear force Vu in the critical section is calculated

as the reaction at the centroid of the critical section minus the self-weight

and any superimposed surface dead and live load acting within the critical

section.

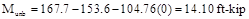

The factored unbalanced moment used for shear

transfer, Munb, is calculated as the sum of the joint moments

to the left and right. Moment of the vertical reaction with respect to the

centroid of the critical section is also taken into account.

For the exterior column:

For the exterior column:

For

the exterior column in Figure 18, the location of the centroidal axis z-z is:

The polar moment Jc of the shear perimeter

is:

ACI 318-14 (Eq. 8.4.4.2.2)

ACI 318-14 (Eq. 8.4.4.2.2)

The length of the critical perimeter for the exterior

column:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

O.K.

O.K.

For the interior

column:

For the interior

column:

For

the interior column in Figure 19, the location of the centroidal axis z-z is:

The polar moment Jc of the shear perimeter

is:

ACI 318-14 (Eq. 8.4.4.2.2)

ACI 318-14 (Eq. 8.4.4.2.2)

The length of the critical perimeter for the exterior

column:

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

O.K.

O.K.

5. Two-Way

Slab Deflection Control (Serviceability Requirements)

Since the slab

thickness was selected based on the minimum slab thickness tables in ACI

318-14, the deflection calculations are not required. However, the calculations

of immediate and time-dependent deflections are covered in this section for

illustration and comparison with spSlab model results.

The calculation of

deflections for two-way slabs is challenging even if linear elastic behavior

can be assumed. Elastic analysis for three service load levels (D, D + Lsustained,

D+LFull) is used to obtain immediate deflections of the two-way

slab in this example. However, other procedures may be used if they result in

predictions of deflection in reasonable agreement with the results of

comprehensive tests. ACI

318-14 (24.2.3)

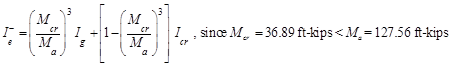

The

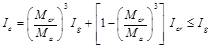

effective moment of inertia (Ie) is used to account for the

cracking effect on the flexural stiffness of the slab. Ie for

uncracked section (Mcr > Ma) is equal to Ig.

When the section is cracked (Mcr < Ma), then

the following equation should be used:

ACI 318-14 (Eq. 24.2.3.5a)

ACI 318-14 (Eq. 24.2.3.5a)

Where:

Ma = Maximum moment in member due to service loads at stage deflection is

calculated.

The

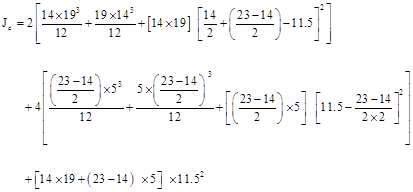

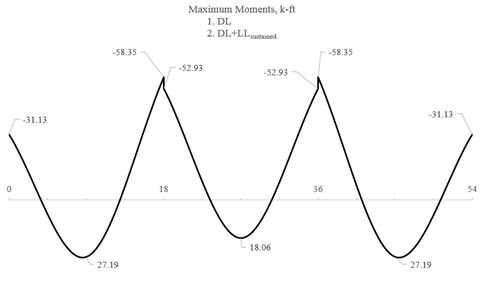

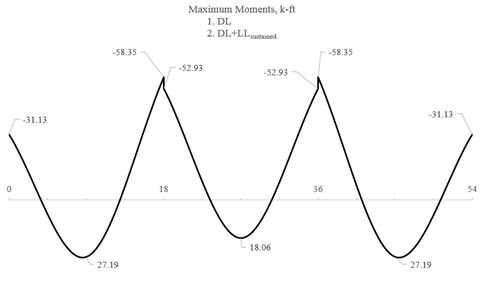

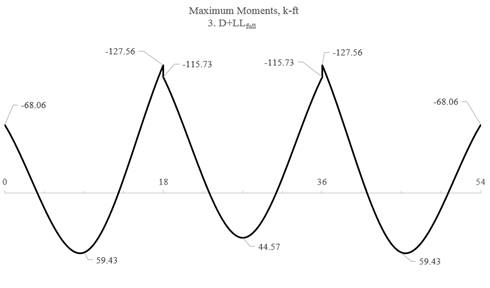

values of the maximum moments for the three service load levels are calculated

from structural analysis as shown previously in this document. These moments are

shown in Figure 20.

Figure 20 – Maximum Moments for the

Three Service Load Levels

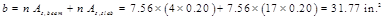

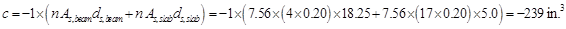

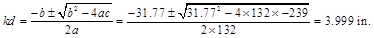

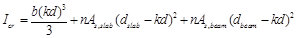

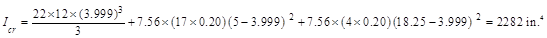

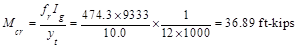

For positive moment (midspan) section of the

exterior span:

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 24.2.3.5b)

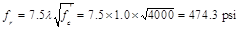

ACI

318-14 (Eq. 19.2.3.1)

ACI

318-14 (Eq. 19.2.3.1)

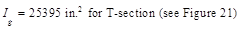

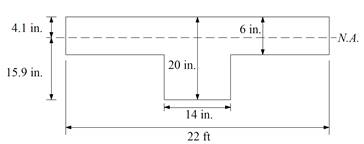

yt = Distance from centroidal axis

of gross section, neglecting reinforcement, to tension face, in.

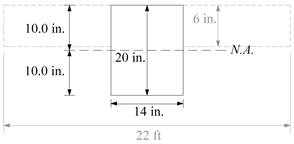

Figure 21 – Ig

calculations for slab section near support

PCA Notes on ACI 318-11 (9.5.2.2)

PCA Notes on ACI 318-11 (9.5.2.2)

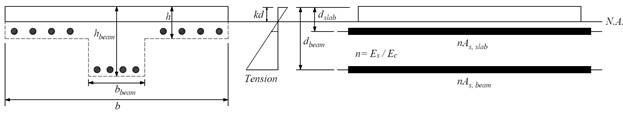

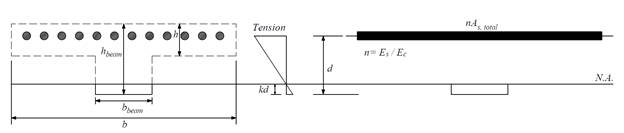

As

calculated previously, the positive reinforcement for the end span frame strip

is 22 #4 bars located at 1.0 in. along the slab section from the bottom of the

slab and 4 #4 bars located at 1.75 in. along the beam section from the bottom

of the beam. Five of the slab section bars are not continuous and will be

excluded from the calculation of Icr. Figure 22 shows all

the parameters needed to calculate the moment of inertia of the cracked section

transformed to concrete at midspan.

Figure 22 – Cracked Transformed

Section (positive moment section)

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

PCA Notes on ACI 318-11 (Table 10-2)

PCA Notes on ACI 318-11 (Table 10-2)

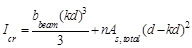

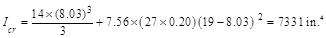

For negative moment section (near the interior

support of the end span):

The

negative reinforcement for the end span frame strip near the interior support

is 27 #4 bars located at 1.0 in. along the section from the top of the slab.

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 19.2.3.1)

ACI

318-14 (Eq. 19.2.3.1)

Figure 23 – Ig

calculations for slab section near support

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

PCA Notes on ACI 318-11 (Table 10-2)

PCA Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA Notes

on ACI 318-11 (Table 10-2)

PCA Notes

on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

Figure 24

– Cracked Transformed Section (interior negative moment section for end span)

The effective moment of inertia procedure described in

the Code is considered sufficiently accurate to estimate deflections. The

effective moment of inertia, Ie, was developed to provide a

transition between the upper and lower bounds of Ig and Icr

as a function of the ratio Mcr/Ma. For conventionally

reinforced (nonprestressed) members, the effective moment of inertia, Ie,

shall be calculated by Eq. (24.2.3.5a) unless obtained by a more comprehensive

analysis.

Ie shall be

permitted to be taken as the value obtained from Eq. (24.2.3.5a) at midspan for

simple and continuous spans, and at the support for cantilevers.

ACI 318-14 (24.2.3.7)

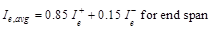

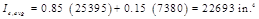

For continuous one-way slabs

and beams. Ie shall be permitted to be taken as the average of

values obtained from Eq. (24.2.3.5a) for the critical positive and negative

moment sections. ACI 318-14 (24.2.3.6)

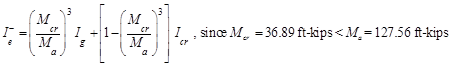

For the exterior span

(span with one end continuous) with service load level (D+LLfull):

ACI

318-14 (24.2.3.5a)

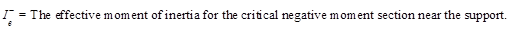

Where

Ie- is the effective moment of inertia for the

critical negative moment section (near the support).

Where

Ie+

is the effective moment of inertia for the critical positive moment section

(midspan).

Since

midspan stiffness (including the effect of cracking) has a dominant effect on

deflections, midspan section is heavily represented in calculation of Ie

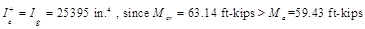

and this is considered satisfactory in approximate deflection calculations. The averaged effective moment of inertia (Ie,avg)

is given by:

PCA

Notes on ACI 318-11 (9.5.2.4(1))

PCA

Notes on ACI 318-11 (9.5.2.4(1))

Where:

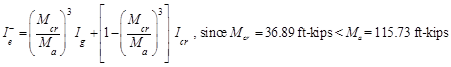

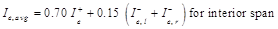

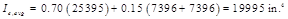

For the interior span

(span with both ends continuous) with service load level (D+LLfull):

ACI

318-14 (24.2.3.5a)

The averaged effective

moment of inertia (Ie,avg) is given by:

PCA Notes on ACI 318-11 (9.5.2.4(2))

PCA Notes on ACI 318-11 (9.5.2.4(2))

Where:

Table 6

provides a summary of the required parameters and calculated values needed for

deflections for exterior and interior equivalent frame. It also provides a

summary of the same values for column strip and middle strip to facilitate

calculation of panel deflection.

|

Table 6 –

Averaged Effective Moment of Inertia Calculations

|

|

For Frame

Strip

|

|

Span

|

zone

|

Ig,

in.4

|

Icr,

in.4

|

Ma,

ft-kip

|

Mcr,

k-ft

|

Ie,

in.4

|

Ie,avg,

in.4

|

|

D

|

D +

LLSus

|

D +

Lfull

|

D

|

D +

LLSus

|

D +

Lfull

|

D

|

D +

LLSus

|

D +

Lfull

|

|

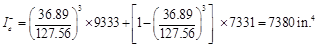

Ext

|

Left

|

9333

|

7147

|

-30.61

|

-30.61

|

-66.92

|

36.89

|

9333

|

9333

|

7513

|

22761

|

22761

|

22693

|

|

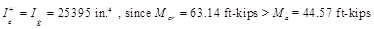

Midspan

|

25395

|

2282

|

27.19

|

27.19

|

59.43

|

63.14

|

25395

|

25395

|

25395

|

|

Right

|

9333

|

7331

|

-58.35

|

-58.35

|

-127.56

|

36.89

|

7837

|

7837

|

7380

|

|

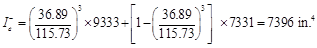

Int

|

Left

|

9333

|

7331

|

-52.93

|

-52.93

|

-115.73

|

36.89

|

8009

|

8009

|

7396

|

20179

|

20179

|

19995

|

|

Mid

|

25395

|

1553

|

18.06

|

18.06

|

44.57

|

63.14

|

25395

|

25395

|

25395

|

|

Right

|

9333

|

7331

|

-52.93

|

-52.93

|

-115.73

|

36.89

|

8009

|

8009

|

7396

|

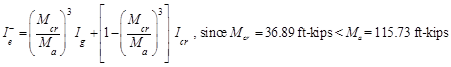

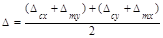

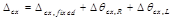

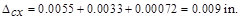

Deflections in two-way slab systems shall be

calculated taking into account size and shape of the panel, conditions of

support, and nature of restraints at the panel edges. For immediate deflections

two-way slab systems the midpanel

deflection is computed as the sum of deflection at midspan of the column strip

or column line in one direction (Δcx or Δcy)

and deflection at midspan of the middle strip in the orthogonal direction (Δmx

or Δmy). Figure 25 shows the deflection computation for

a rectangular panel. The average Δ for panels that have different

properties in the two direction is calculated as follows:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 8)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 8)

Figure 25 – Deflection Computation

for a rectangular Panel

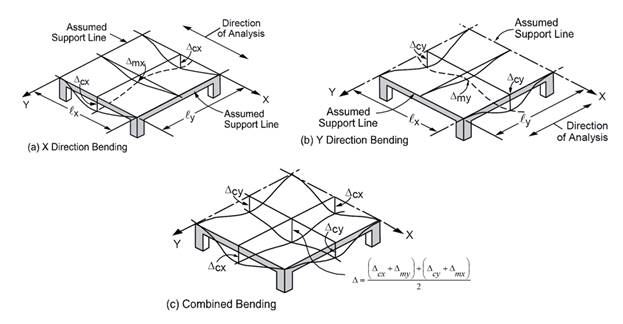

To

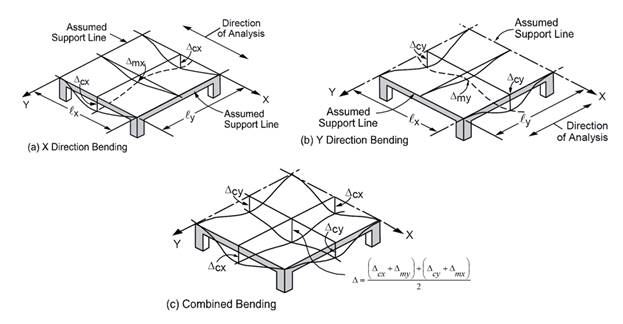

calculate each term of the previous equation, the following procedure should be

used. Figure 26 shows the procedure of calculating the term Δcx.

same procedure can be used to find the other terms.

Figure 26 –Δcx calculation

procedure

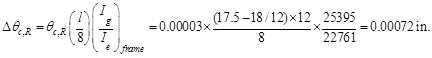

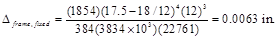

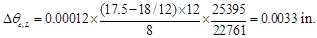

For exterior span - service

dead load case:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 10)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 10)

Where:

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

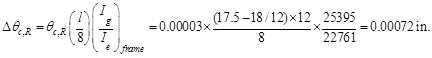

Iframe,averaged =

The averaged effective moment of inertia (Ie,avg)

for the frame strip for service dead load case from Table 6 = 22761 in.4

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 11)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 11)

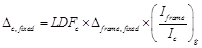

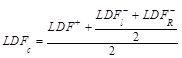

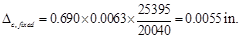

Where LDFc

is the load distribution factor for the column strip. The load distribution

factor for the column strip can be found from the following equation:

And the load distribution

factor for the middle strip can be found from the following equation:

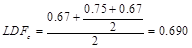

For the

end span, LDF for exterior negative region (LDFL¯), interior

negative region (LDFR¯), and positive region (LDFL+) are 0.75, 0.67, and 0.67, respectively (From Table 2 of this document).

Thus, the load distribution factor for the column strip for the end span is

given by:

Ic,g

= The gross moment of inertia (Ig)

for the column strip (for T section) = 20040 in.4

Iframe,g

= The gross moment of inertia (Ig)

for the frame strip (for T section) = 25395 in.4

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 12)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 12)

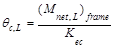

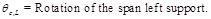

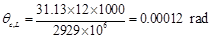

Where:

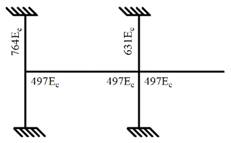

Kec = effective column stiffness

for exterior column.

= 764 x

Ec = 2929 x 106 in.-lb

(calculated previously).

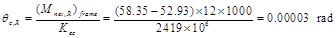

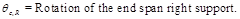

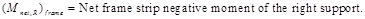

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 14)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 14)

Where:

Where

Kec = effective column stiffness

for interior column.

= 631 x

Ec = 2419 x 106 in.-lb

(calculated previously).

Where:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 9)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 9)

Following

the same procedure, Δmx can be calculated for the middle

strip. This procedure is repeated for the equivalent frame in the orthogonal

direction to obtain Δcy, and Δmy

for the end and middle spans for the other load levels (D+LLsus

and D+LLfull).

Assuming

square panel, Δcx = Δcy= 0.009

in. and Δmx = Δmy=

0.021 in.

The

average Δ for the corner panel is calculated as follows: