Code

Building

Code Requirements for Structural Concrete (ACI 318-14) and Commentary (ACI

318R-14)

Reference

Concrete

Floor Systems (Guide to Estimating and Economizing), Second Edition, 2002 David

A. Fanella, Portland Cement Association.

PCA

Notes on ACI 318-11 Building Code Requirements for Structural Concrete, Twelfth

Edition, 2013, Portland Cement Association.

Simplified

Design of Reinforced Concrete Buildings, Fourth Edition, 2011 Mahmoud E. Kamara

and Lawrence C. Novak

Control

of Deflection in Concrete Structures (ACI 435R-95), American Concrete Institute

Reinforced

Concrete Design .. .Hassoun, McGraw Hill

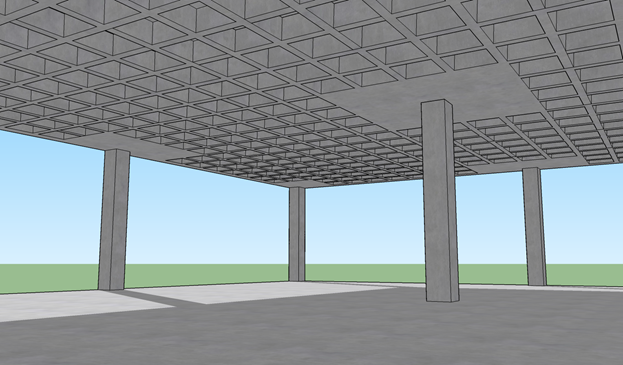

Design Data

Story Height = 13 ft

(provided by architectural drawings)

Superimposed Dead Load,

SDL = 50 psf for Frame walls, hollow concrete masonry unit wythe, 12 in.

thick, 125 pcf unit density, with no grout

ASCE/SEI

7-10 (Table C3-1)

Live Load, LL =

100 psf for Recreational uses – Gymnasiums ASCE/SEI

7-10 (Table 4-1)

fc’ = 5000 psi (for slab)

fc’ = 6000 psi (for columns)

fy = 60,000 psi

Solution

Preliminary Flat Plate (without Joists)

a.

Slab minimum

thickness – Deflection ACI

318-14 (8.3.1.1)

In lieu of

detailed calculation for deflections, ACI 318 minimum slab thickness for

two-way construction without interior beams is given in Table 8.3.1.1.

For flat plate slab system,

the minimum slab thickness per ACI 318-14 are:

ACI 318-14 (Table 8.3.1.1)

ACI 318-14 (Table 8.3.1.1)

But not less than 5 in. ACI

318-14 (8.3.1.1(a))

ACI 318-14 (Table 8.3.1.1)

ACI 318-14 (Table 8.3.1.1)

But not less than 5 in. ACI

318-14 (8.3.1.1(a))

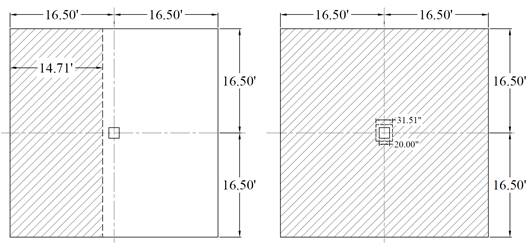

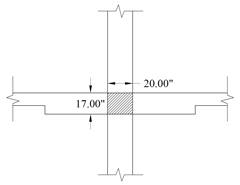

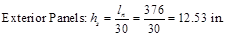

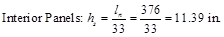

Where ln

= length of clear span in the long direction = 33 x 12 – 20 = 376 in.

Use 13 in. slab for all

panels (self-weight = 150 pcf x 13 in. /12 = 162.5 psf)

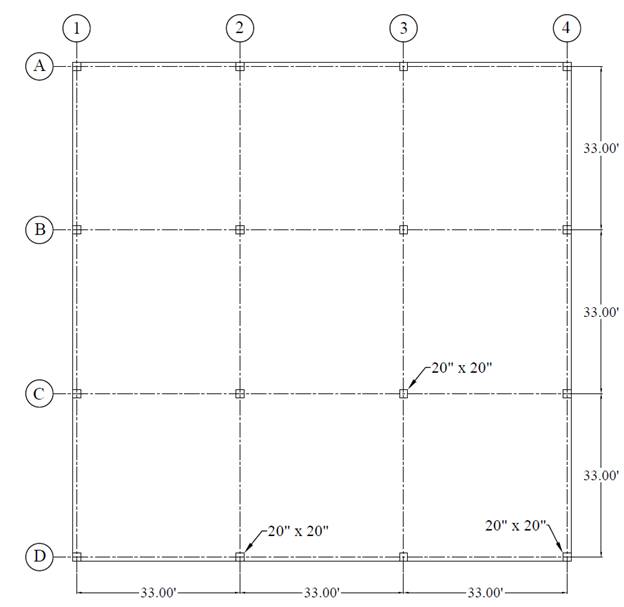

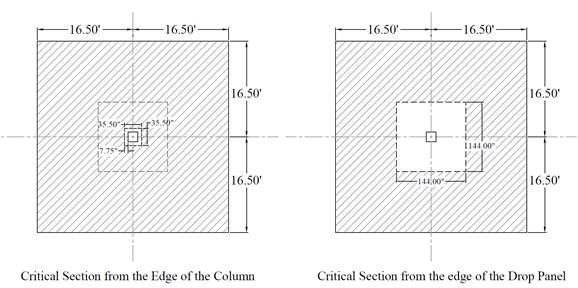

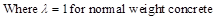

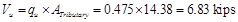

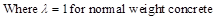

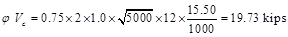

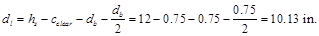

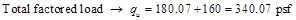

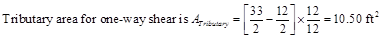

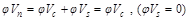

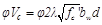

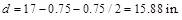

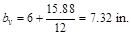

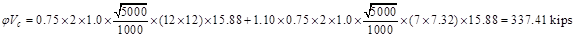

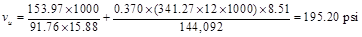

b. Slab shear strength – one way shear

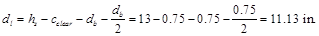

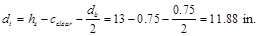

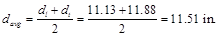

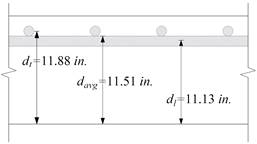

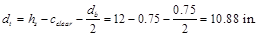

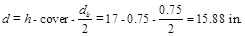

Evaluate the average

effective depth (Figure 2):

Where:

cclear = 3/4 in. for

# 6 steel bar ACI

318-14 (Table 20.6.1.3.1)

db = 0.75 in. for # 6 steel bar

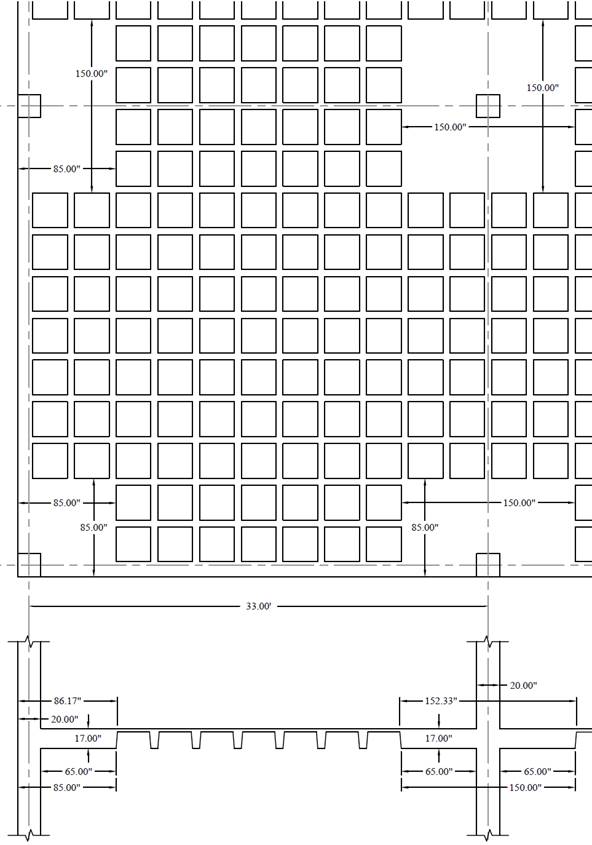

Figure 2 - Two-Way Flat Concrete Floor System

ACI

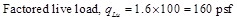

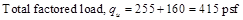

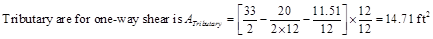

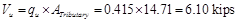

318-14 (5.3.1)

ACI

318-14 (5.3.1)

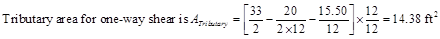

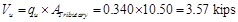

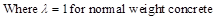

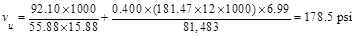

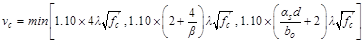

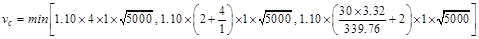

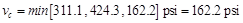

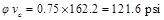

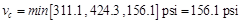

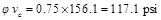

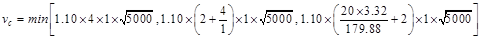

Check the adequacy of

slab thickness for beam action (one-way shear) ACI

318-14 (22.5)

at an interior column:

Consider a 12-in. wide

strip. The critical section for one-way shear is located at a distance d,

from the face of support (see Figure 3):

ACI

318-14 (Eq. 22.5.5.1)

ACI

318-14 (Eq. 22.5.5.1)

Slab thickness of 13 in.

is adequate for one-way shear.

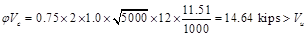

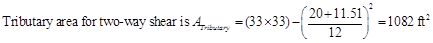

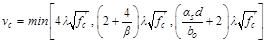

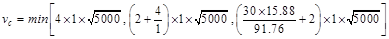

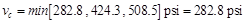

c.

Slab shear

strength – two-way shear

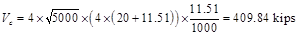

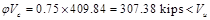

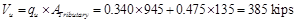

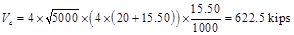

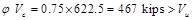

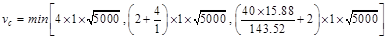

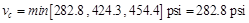

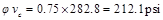

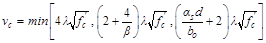

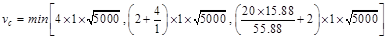

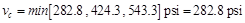

Check the adequacy of

slab thickness for punching shear (two-way shear) at an interior column (Figure

4):

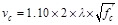

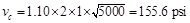

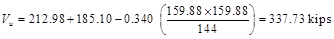

ACI

318-14 (Table 22.6.5.2(a))

ACI

318-14 (Table 22.6.5.2(a))

Slab thickness of 13 in. is not adequate

for two-way shear. This is expected as the self-weight an applied loads are very

challenging for a flat plate system.

Figure 3 –

Critical Section for One-Way Shear Figure 4 – Critical Section for Two-Way Shear

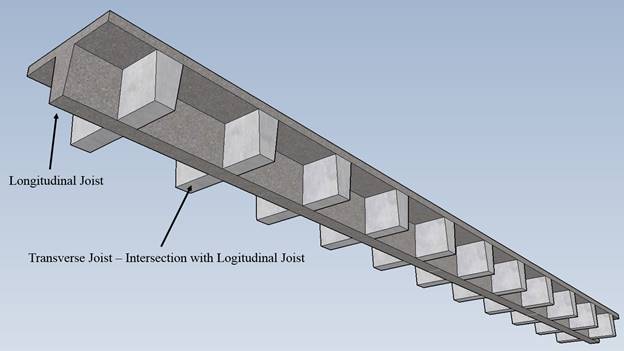

In

this case, four options can be considered: 1) increase the slab thickness

further, 2) use headed shear reinforcement in the slab, 3) apply drop panels at

columns, or 4) use two-way joist slab system. In this example, the latter

option will be used to achieve better understanding for the design of two-way joist

slab often called two-way ribbed slab or waffle slab.

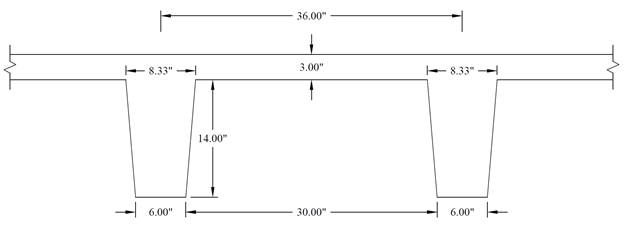

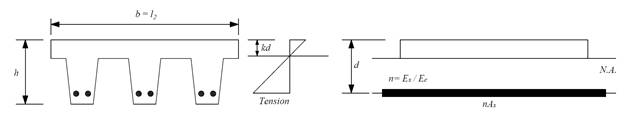

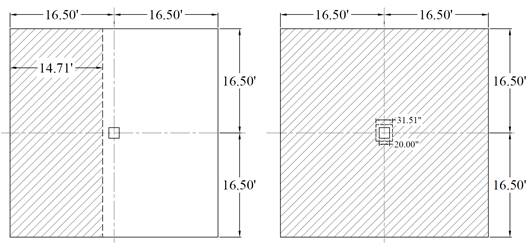

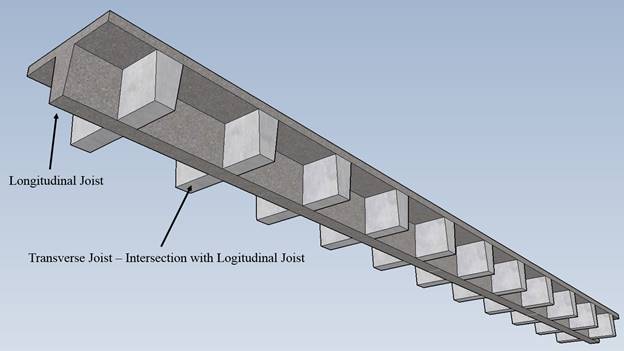

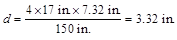

Check the applicable joist

dimensional limitations as follows:

1)

Width of ribs

shall be at least 4 in. at any location along the depth. ACI

318-14 (9.8.1.2)

Use ribs with 6 in. width.

2)

Overall depth of

ribs shall not exceed 3.5 times the minimum width. ACI

318-14 (9.8.1.3)

3.5 x 6 in. = 21 in. à Use ribs with 14 in. depth.

3)

Clear spacing

between ribs shall not exceed 30 in. ACI

318-14 (9.8.1.4)

Use 30 in. clear spacing.

4)

Slab thickness (with

removable forms) shall be at least the greater of: ACI

318-14 (8.8.3.1)

a)

1/12 clear

distance between ribs = 1/12 x 30 = 2.5 in.

b)

2 in.

Use a slab thickness of 3

in. > 2.5 in.

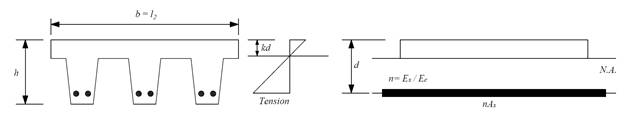

Figure 5 – Joists Dimensions

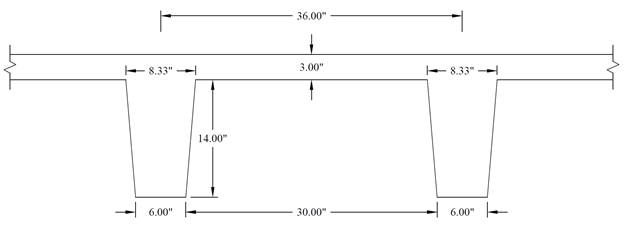

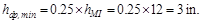

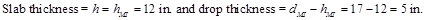

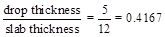

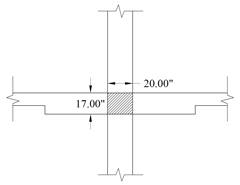

In waffle slabs a drop panel is

automatically invoked to guarantee adequate two-way (punching) shear resistance

at column supports. This is evident from the flat plate check conducted using

13 in. indicating insufficient punching shear capacity above. Check the drop panel dimensional limitations as

follows:

1)

The drop panel

shall project below the slab at least one-fourth of the adjacent slab

thickness.

ACI

318-14 (8.2.4(a))

Since the slab thickness (hMI – calculated in page 7 of this

document) is 12 in., the thickness of the drop panel should be at least:

Drop panel depth are also controlled

by the rib depth (both at the same level).For nominal lumber size (2x), hdp

= hrib = 14 in. > hdp, min = 3

in.

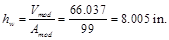

The total thickness including the actual

slab and the drop panel thickness (h) = hs + hdp

= 3 + 14 = 17 in.

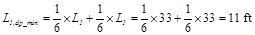

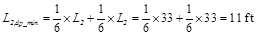

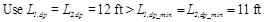

2)

The drop panel

shall extend in each direction from the centerline of support a distance not

less than one-sixth the span length measured from center-to-center of supports

in that direction.

ACI

318-14 (8.2.4(b))

Based on the previous

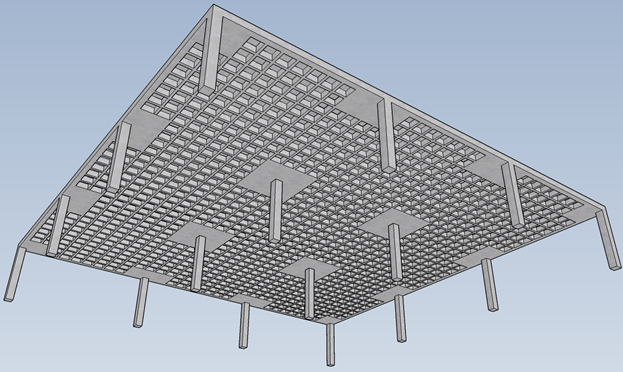

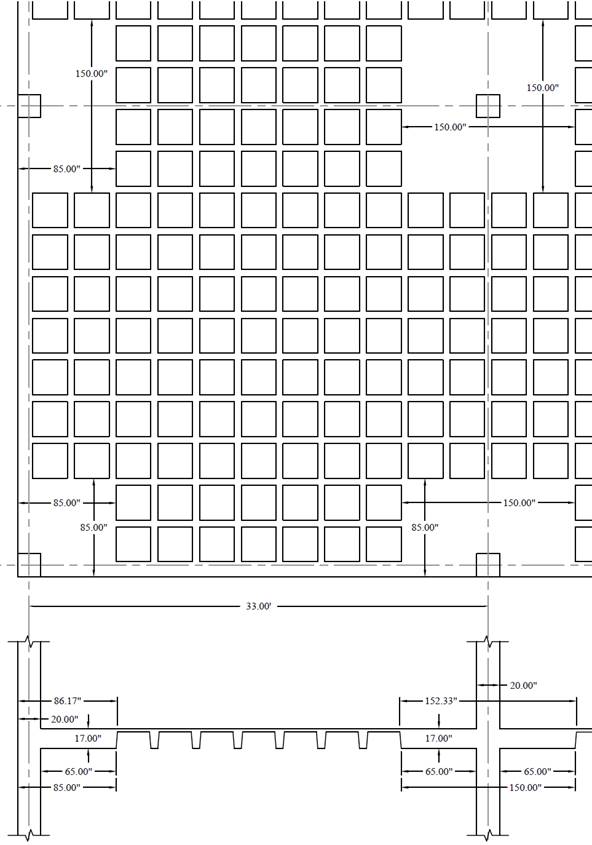

discussion, Figure 6 shows the dimensions of the selected two-way joist system.

Figure 6 – Two-Way Joist (Waffle) Slab

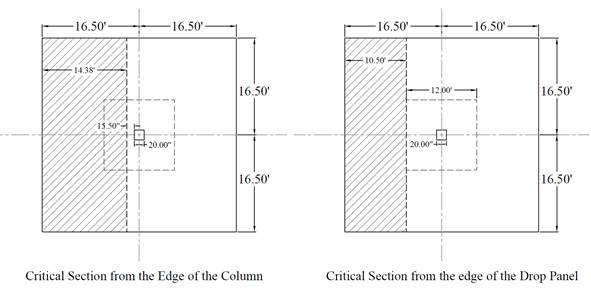

Preliminary Two-Way Joist Slab (Waffle Slab)

For slabs with changes in thickness and subjected to

bending in two directions, it is necessary to check shear at multiple sections

as defined in the ACI 318-14. The critical sections shall

be located with respect to:

1) Edges or corners of

columns. ACI 318-14 (22.6.4.1(a))

2) Changes in slab

thickness, such as edges of drop panels. ACI 318-14 (22.6.4.1(b))

a.

Slab minimum

thickness – Deflection ACI

318-14 (8.3.1.1)

In lieu of

detailed calculation for deflections, ACI 318 Code gives minimum slab thickness

for two-way construction without interior beams in Table 8.3.1.1.

For this slab system, the

minimum slab thicknesses per ACI 318-14 are:

ACI 318-14 (Table 8.3.1.1)

ACI 318-14 (Table 8.3.1.1)

But not less than 4 in. ACI

318-14 (8.3.1.1(b))

ACI 318-14 (Table 8.3.1.1)

ACI 318-14 (Table 8.3.1.1)

But not less than 4 in. ACI

318-14 (8.3.1.1(b))

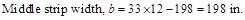

Where ln

= length of clear span in the long direction = 33 x 12 – 20 = 376 in.

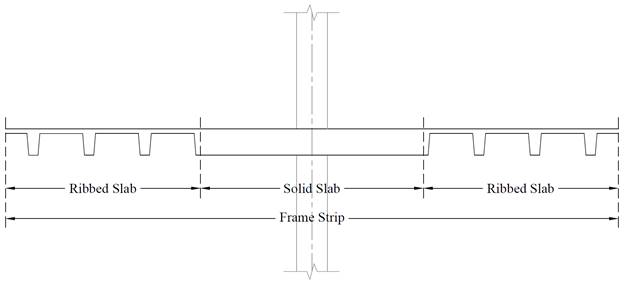

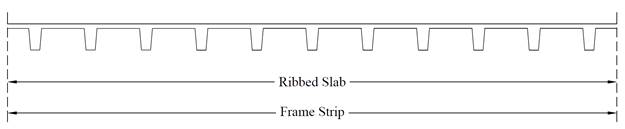

For the purposes of

analysis and design, the ribbed slab will be replaced with a solid slab of

equivalent moment of inertia, weight, punching shear capacity, and one-way

shear capacity.

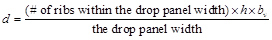

The

equivalent thickness based on moment of inertia is used to find slab stiffness

considering the ribs in the direction of the analysis only. The ribs spanning

in the transverse direction are not considered in the stiffness computations.

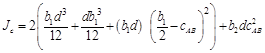

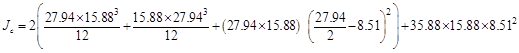

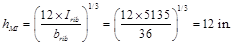

This thickness, hMI, is given by:

spSlab Software Manual (Eq. 2-11)

spSlab Software Manual (Eq. 2-11)

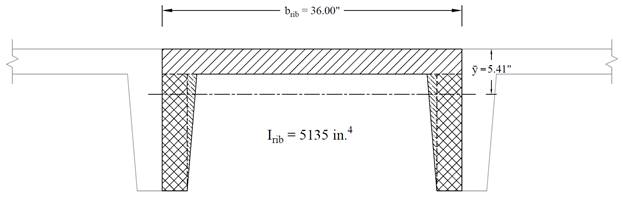

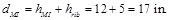

Where:

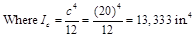

Irib = Moment of inertia of one joist

section between centerlines of ribs (see Figure 7a).

brib = The center-to-center distance

of two ribs (clear rib spacing plus rib width) (see Figure 7a).

Since hMI

= 12 in. > hmin = 11.4 in., the deflection calculation can

be neglected. However, the deflection calculation will be included in this

example for comparison with the spSlab software results.

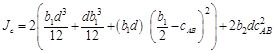

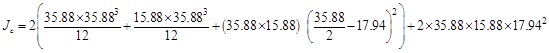

The drop

panel depth for two-way joist (waffle) slab is set equal to the rib depth. The

equivalent drop depth based on moment of inertia, dMI, is

given by:

spSlab Software Manual (Eq. 2-12)

spSlab Software Manual (Eq. 2-12)

Where hrib

= 3 + 14 – 12 = 5 in.

Figure 7a – Equivalent Thickness Based on Moment of Inertia

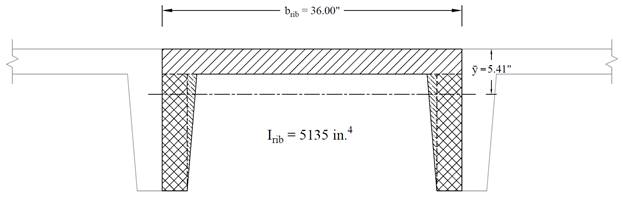

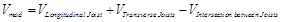

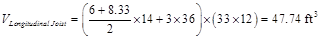

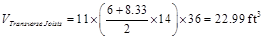

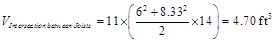

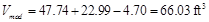

Find system self-weight

using the equivalent thickness based on the weight of individual components

(see the following Figure). This thickness, hw, is given by:

spSlab Software Manual (Eq. 2-10)

spSlab Software Manual (Eq. 2-10)

Where:

Vmod = The Volume of one joist module

(the transverse joists are included – 11 joists in the frame strip).

Amod = The plan area of one joist module

= 33 x 36/12 = 99 ft2

Self-weight for slab

section without drop panel = 150 pcf x 8 in. /12 = 100.057 psf

Self-weight for drop panel = 150 pcf x

(14 + 3 – 8) in. /12 = 112.44 psf

Figure 7b

– Equivalent Thickness Based on the Weight of Individual Components

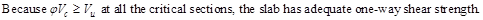

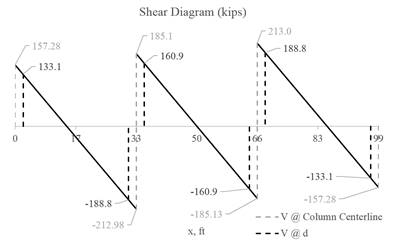

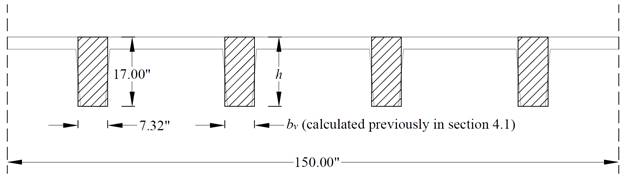

b. Slab shear strength – one-way shear

For critical section

at distance d from the edge of the column (slab section with drop

panel):

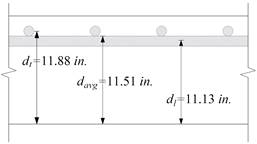

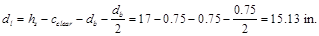

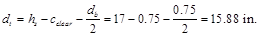

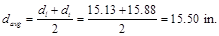

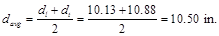

Evaluate the average

effective depth:

Where:

cclear = 3/4 in. for # 6 steel bar ACI

318-14 (Table 20.6.1.3.1)

db = 0.75 in. for # 6 steel bar

hs = 17 in. = The drop depth (dMI)

ACI

318-14 (5.3.1)

ACI

318-14 (5.3.1)

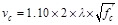

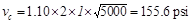

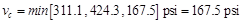

Check the adequacy of

slab thickness for beam action (one-way shear) from the edge of the interior

column

ACI 318-14 (22.5)

Consider a 12-in. wide

strip. The critical section for one-way shear is located at a distance d,

from the edge of the column (see Figure 8)

ACI

318-14 (Eq. 22.5.5.1)

ACI

318-14 (Eq. 22.5.5.1)

Slab thickness is

adequate for one-way shear for the first critical section (from the edge of the

column).

For critical section

at the edge of the drop panel (slab section without drop panel):

Evaluate the average

effective depth:

Where:

cclear = 3/4 in. for

# 6 steel bar ACI

318-14 (Table 20.6.1.3.1)

db = 0.75 in. for # 6 steel bar

ACI

318-14 (5.3.1)

ACI

318-14 (5.3.1)

Check the

adequacy of slab thickness for beam action (one-way shear) from the edge of the

interior drop panel ACI 318-14 (22.5)

Consider a 12-in. wide

strip. The critical section for one-way shear is located at the face of the solid

head (see Figure 8)

ACI

318-14 (Eq. 22.5.5.1)

ACI

318-14 (Eq. 22.5.5.1)

Slab thickness of 12 in.

is adequate for one-way shear for the second critical section (at the edge of

the drop panel).

Figure 8 – Critical Sections for One-Way Shear

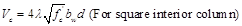

c.

Slab shear

strength – two-way shear

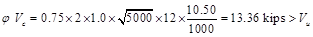

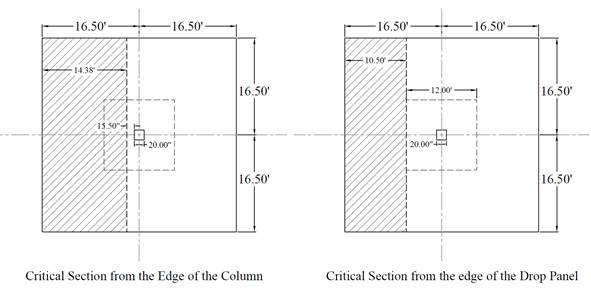

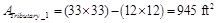

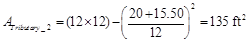

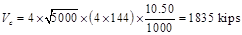

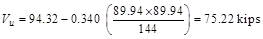

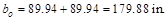

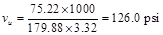

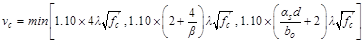

For critical section at distance d/2 from the edge of the column

(slab section with drop panel):

Check the adequacy of slab thickness

for punching shear (two-way shear) at an interior column (Figure 9):

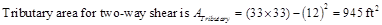

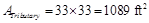

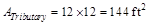

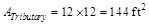

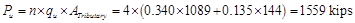

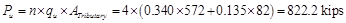

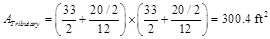

Tributary area of two-way

shear for the slab without the drop panel is:

Tributary area of two-way

shear for the slab with the drop panel is:

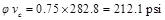

ACI

318-14 (Table 22.6.5.2(a))

ACI

318-14 (Table 22.6.5.2(a))

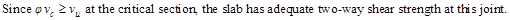

Slab thickness is adequate for

two-way shear for the first critical section (from the edge of the column).

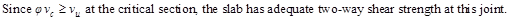

For critical section at the edge of the drop panel

(slab section without drop panel):

Check the adequacy of slab thickness

for punching shear (two-way shear) at an interior drop panel (Figure 9):

ACI

318-14 (Table 22.6.5.2(a))

ACI

318-14 (Table 22.6.5.2(a))

Slab thickness of 12 in. is adequate

for two-way shear for the second critical section (from the edge of the drop

panel).

Figure 9 – Critical Sections for Two-Way Shear

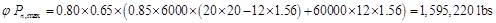

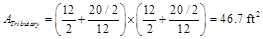

d. Column dimensions - axial load

Check the adequacy of

column dimensions for axial load:

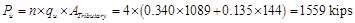

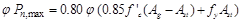

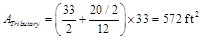

Tributary area for

interior column for live load, superimposed dead load, and self-weight of the

slab is

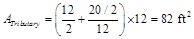

Tributary area for

interior column for self-weight of additional slab thickness due to the

presence of the drop panel is

Assuming four story

building

Assume 20 in. square

column with 12 – No. 11 vertical bars with design axial strength, φPn,max

of

ACI

318-14 (22.4.2)

ACI

318-14 (22.4.2)

Column dimensions of 20 in. x 20

in. are adequate for axial load.

ACI 318 states that a slab system shall be designed by

any procedure satisfying equilibrium and geometric compatibility, provided that

strength and serviceability criteria are satisfied. Distinction of two-systems

from one-way systems is given by ACI 318-14 (R8.10.2.3 & R8.3.1.2).

ACI 318 permits the use of Direct

Design Method (DDM) and Equivalent Frame Method (EFM) for the gravity load

analysis of orthogonal frames and is applicable to flat plates, flat slabs, and

slabs with beams. The following sections outline the solution per EFM and

spSlab software. For the solution per DDM, check the flat plate example.

EFM is the most comprehensive and

detailed procedure provided by the ACI 318 for the analysis and design of

two-way slab systems where the structure is modeled by a series of equivalent

frames (interior and exterior) on column lines taken longitudinally and

transversely through the building.

The equivalent frame consists of three

parts (for a detailed discussion of this method, refer to the

flat plate design example):

1) Horizontal slab-beam strip.

2) Columns or other vertical supporting

members.

3) Elements of the structure (Torsional

members) that provide moment transfer between the horizontal and vertical

members.

In EFM, live load shall be arranged in accordance with

6.4.3 which requires slab systems to be analyzed and designed for the most

demanding set of forces established by investigating the effects of live load

placed in various critical patterns. ACI 318-14 (8.11.1.2 & 6.4.3)

Complete analysis must include representative interior

and exterior equivalent frames in both the longitudinal and transverse

directions of the floor. ACI 318-14 (8.11.2.1)

Panels

shall be rectangular, with a ratio of longer to shorter panel dimensions,

measured center-to-center of supports, not to exceed 2. ACI 318-14 (8.10.2.3)

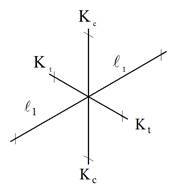

Determine moment distribution factors and fixed-end

moments for the equivalent frame members. The moment distribution procedure

will be used to analyze the equivalent frame. Stiffness factors k, carry over factors COF, and fixed-end moment factors

FEM for the slab-beams and column members are determined using the design aids tables

at Appendix 20A of PCA Notes on ACI 318-11. These

calculations are shown below.

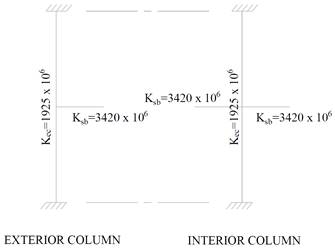

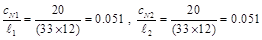

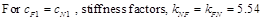

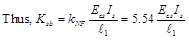

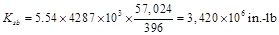

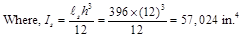

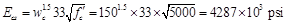

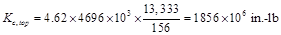

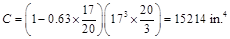

a. Flexural stiffness of slab-beams at

both ends, Ksb.

PCA Notes

on ACI 318-11 (Table A1)

PCA Notes

on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

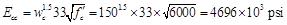

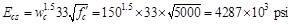

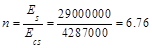

ACI 318-14 (19.2.2.1.a)

ACI 318-14 (19.2.2.1.a)

Carry-over factor COF = 0.54 PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

Uniform load fixed end moment coefficient, mNF1

= 0.0911

Fixed end moment coefficient for (b-a) = 0.2 when a =

0, mNF2 = 0.0171

Fixed end moment coefficient for (b-a) = 0.2 when a = 0.8, mNF3

= 0.0016

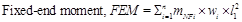

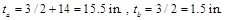

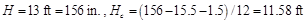

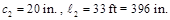

b.

Flexural

stiffness of column members at both ends, Kc.

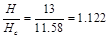

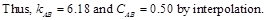

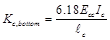

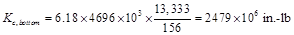

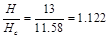

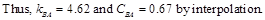

Referring to Table A7, Appendix 20A,

For the Bottom Column:

PCA

Notes on ACI 318-11 (Table A7)

PCA

Notes on ACI 318-11 (Table A7)

ACI 318-14 (19.2.2.1.a)

ACI 318-14 (19.2.2.1.a)

lc = 13 ft = 156 in.

For the Top Column:

PCA

Notes on ACI 318-11 (Table A7)

PCA

Notes on ACI 318-11 (Table A7)

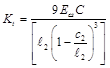

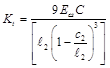

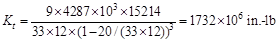

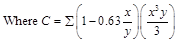

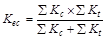

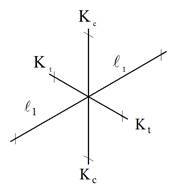

c. Torsional stiffness of torsional

members,  .

.

ACI 318-14 (R.8.11.5)

ACI 318-14 (R.8.11.5)

ACI 318-14 (Eq. 8.10.5.2b)

ACI 318-14 (Eq. 8.10.5.2b)

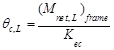

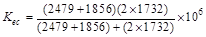

d. Equivalent column stiffness Kec.

Where∑

Kt is for two torsional

members one on each side of the column, and ∑ Kc is for

the upper and lower columns at the slab-beam joint of an intermediate floor.

Figure

10 – Torsional Member Figure 11 – Column and Edge of Slab

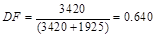

e.

Slab-beam joint

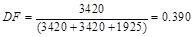

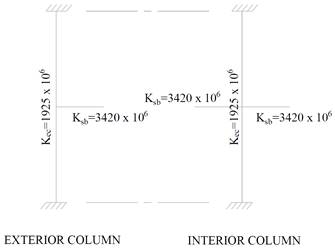

distribution factors, DF.

At exterior joint,

At interior joint,

COF for slab-beam =0.576

Figure 12 – Slab and Column Stiffness

Determine negative and positive moments for the

slab-beams using the moment distribution method. Since the unfactored live load

does not exceed three-quarters of the unfactored dead load, design moments are

assumed to occur at all critical sections with full factored live on all spans. ACI

318-14 (6.4.3.2)

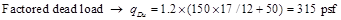

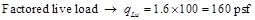

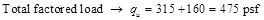

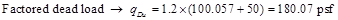

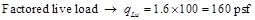

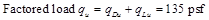

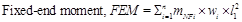

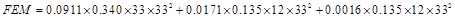

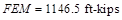

a. Factored load and Fixed-End Moments

(FEM’s).

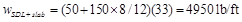

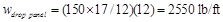

For slab:

For drop panels:

PCA

Notes on ACI 318-11 (Table A1)

PCA

Notes on ACI 318-11 (Table A1)

b. Moment distribution. Computations are

shown in Table 1. Counterclockwise rotational moments acting on the member ends

are taken as positive. Positive span moments are determined from the following

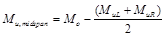

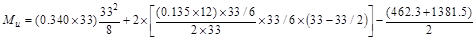

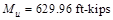

equation:

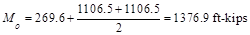

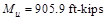

Where Mo is the

moment at the midspan for a simple beam.

When the end moments are not equal, the maximum moment

in the span does not occur at the midspan, but its value is close to that

midspan for this example.

Positive moment in span 1-2:

|

Table 1 - Moment Distribution for Equivalent Frame

|

|

|

|

Joint

|

1

|

2

|

3

|

4

|

|

Member

|

1-2

|

2-1

|

2-3

|

3-2

|

3-4

|

4-3

|

|

DF

|

0.640

|

0.390

|

0.390

|

0.390

|

0.390

|

0.640

|

|

COF

|

0.576

|

0.576

|

0.576

|

0.576

|

0.576

|

0.576

|

|

FEM

|

1146.51

|

-1146.5

|

1146.51

|

-1146.5

|

1146.51

|

-1146.5

|

|

Dist

|

-733.6

|

0.0

|

0.0

|

0.0

|

0.0

|

733.6

|

|

CO

|

0.0

|

-422.5

|

0.0

|

0.0

|

422.5

|

0.0

|

|

Dist

|

0.0

|

164.8

|

164.8

|

-164.8

|

-164.8

|

0.0

|

|

CO

|

94.9

|

0.0

|

-94.9

|

94.9

|

0.0

|

-94.9

|

|

Dist

|

-60.7

|

37.0

|

37.0

|

-37.0

|

-37.0

|

60.7

|

|

CO

|

21.3

|

-35.0

|

-21.3

|

21.3

|

35.0

|

-21.3

|

|

Dist

|

-13.7

|

22.0

|

22.0

|

-22.0

|

-22.0

|

13.7

|

|

CO

|

12.7

|

-7.9

|

-12.7

|

12.7

|

7.9

|

-12.7

|

|

Dist

|

-8.1

|

8.0

|

8.0

|

-8.0

|

-8.0

|

8.1

|

|

CO

|

4.6

|

-4.7

|

-4.6

|

4.6

|

4.7

|

-4.6

|

|

Dist

|

-3.0

|

3.6

|

3.6

|

-3.6

|

-3.6

|

3.0

|

|

CO

|

2.1

|

-1.7

|

-2.1

|

2.1

|

1.7

|

-2.1

|

|

Dist

|

-1.3

|

1.5

|

1.5

|

-1.5

|

-1.5

|

1.3

|

|

CO

|

0.9

|

-0.8

|

-0.9

|

0.9

|

0.8

|

-0.9

|

|

Dist

|

-0.6

|

0.6

|

0.6

|

-0.6

|

-0.6

|

0.6

|

|

CO

|

0.4

|

-0.3

|

-0.4

|

0.4

|

0.3

|

-0.4

|

|

Dist

|

-0.2

|

0.3

|

0.3

|

-0.3

|

-0.3

|

0.2

|

|

CO

|

0.2

|

-0.1

|

-0.2

|

0.2

|

0.1

|

-0.2

|

|

Dist

|

-0.1

|

0.1

|

0.1

|

-0.1

|

-0.1

|

0.1

|

|

CO

|

0.1

|

-0.1

|

-0.1

|

0.1

|

0.1

|

-0.1

|

|

Dist

|

0.0

|

0.1

|

0.1

|

-0.1

|

-0.1

|

0.0

|

|

CO

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

|

Dist

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

0.0

|

|

M, k-ft

|

462.3

|

-1381.5

|

1247.5

|

-1247.5

|

1381.5

|

-462.3

|

|

Midspan M,

ft-kips

|

630.0

|

304.4

|

630.0

|

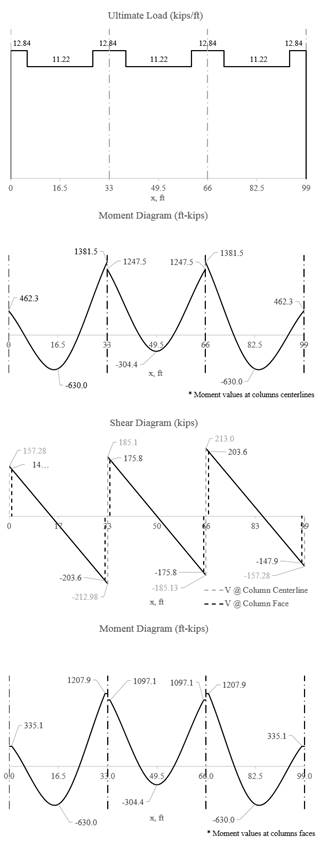

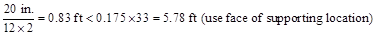

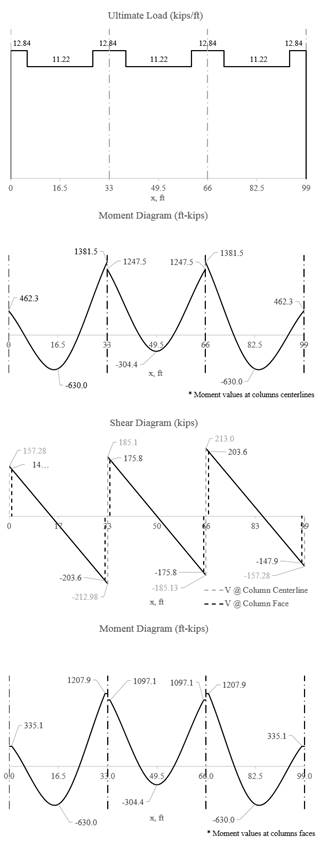

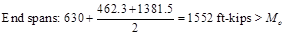

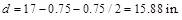

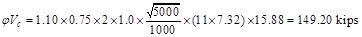

Positive and

negative factored moments for the slab system in the direction of analysis are

plotted in Figure 13. The negative moments used for design are taken at the

faces of supports (rectangle section or equivalent rectangle for circular or

polygon sections) but not at distances greater than 0.175 l1

from the centers of supports. ACI

318-14 (8.11.6.1)

Figure 13 -

Positive and Negative Design Moments for Slab-Beam (All Spans Loaded with Full

Factored Live Load)

a. Check whether the moments calculated above can take

advantage of the reduction permitted by ACI 318-14 (8.11.6.5):

If the slab

system analyzed using EFM within the limitations of ACI 318-14

(8.10.2), it is permitted by the ACI code to reduce the calculated

moments obtained from EFM in such proportion that the absolute sum of the

positive and average negative design moments need not exceed the total static

moment Mo given by Equation 8.10.3.2 in

the ACI 318-14.

Check Applicability

of Direct Design Method:

1.

There is a

minimum of three continuous spans in each direction. ACI

318-14 (8.10.2.1)

2.

Successive span

lengths are equal. ACI

318-14 (8.10.2.2)

3.

Long-to-Short

ratio is 33/33 = 1.0 < 2.0. ACI

318-14 (8.10.2.3)

4.

Columns are not

offset. ACI

318-14 (8.10.2.4)

5.

Loads are gravity

and uniformly distributed with service live-to-dead ratio of 0.67 < 2.0

(Note: The self-weight of the drop

panels is not uniformly distributed entirely along the span. However, the

variation in load magnitude is small).

ACI

318-14 (8.10.2.5 and 6)

6.

Check relative

stiffness for slab panel. ACI

318-14 (8.10.2.7)

Slab

system is without beams and this requirement is not applicable.

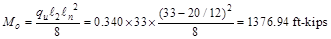

ACI 318-14 (Eq. 8.10.3.2)

ACI 318-14 (Eq. 8.10.3.2)

To illustrate proper procedure, the interior span

factored moments may be reduced as follows:

Permissible reduction = 1376.9/1552 = 0.887

Adjusted negative

design moment = 1247.5 × 0.887 = 1106.5 ft-kips

Adjusted positive

design moment = 304 × 0.887 = 269.6 ft-kips

ACI 318 allows the reduction of the moment values

based on the previous procedure. Since the drop panels may cause gravity loads

not to be uniform (Check limitation #5 and Figure 13), the moment values

obtained from EFM will be used for comparison reasons.

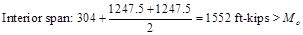

b. Distribute factored moments to column and middle

strips:

After the negative and positive moments have been

determined for the slab-beam strip, the ACI code permits the distribution of

the moments at critical sections to the column strips, beams (if any), and

middle strips in accordance with the DDM. ACI

318-14 (8.11.6.6)

Distribution of factored moments at critical sections

is summarized in Table 2.

|

Table 2 - Distribution of factored

moments

|

|

|

Slab-beam Strip

|

Column Strip

|

Middle Strip

|

|

Moment

(ft-kips)

|

Percent

|

Moment

(ft-kips)

|

Percent

|

Moment

(ft-kips)

|

|

End Span

|

Exterior Negative

|

335.1

|

100

|

335.1

|

0

|

0.0

|

|

Positive

|

630.0

|

60

|

378.0

|

40

|

252.0

|

|

Interior Negative

|

1207.9

|

75

|

905.9

|

25

|

302.0

|

|

Interior Span

|

Negative

|

1097.1

|

75

|

822.8

|

25

|

274.3

|

|

Positive

|

304.4

|

60

|

182.6

|

40

|

121.8

|

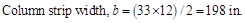

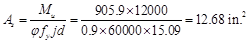

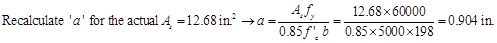

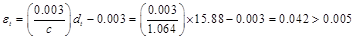

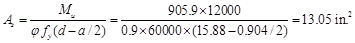

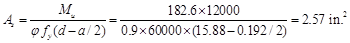

a. Determine flexural reinforcement required for strip

moments

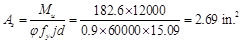

The flexural reinforcement calculation for the column

strip of end span – interior negative location:

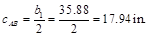

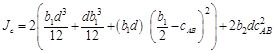

Use d = 15.88 in. (slab with drop panel where h

= 17 in.)

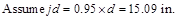

To determine the area of steel, assumptions have to be

made whether the section is tension or compression controlled, and regarding

the distance between the resultant compression and tension forces along the

slab section (jd). In this example, tension-controlled section will be

assumed so the reduction factor is equal to 0.9, and jd will be taken equal to 0.95d.

The assumptions will be verified once the area of steel in finalized.

is equal to 0.9, and jd will be taken equal to 0.95d.

The assumptions will be verified once the area of steel in finalized.

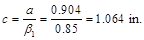

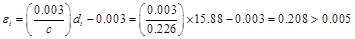

Therefore, the assumption that section is

tension-controlled is valid.

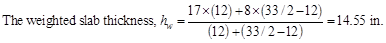

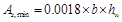

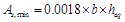

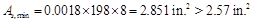

Two values of thickness must be considered. The slab

thickness in the column strip is 17 in. with the drop panel and 8 in. for the equivalent

slab without the drop panel based on the system weight.

ACI 318-14 (24.4.3.2)

ACI 318-14 (24.4.3.2)

ACI 318-14 (24.4.3.3)

ACI 318-14 (24.4.3.3)

Provide 30 - #6 bars with As = 13.20

in.2 and s = 198/30 = 6.6 in. ≤ smax

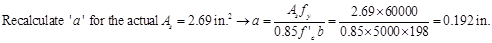

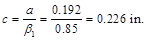

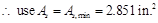

The flexural reinforcement calculation for the column

strip of interior span – positive location:

Use d = 15.88 in. (slab with rib where h

= 17 in.)

To determine the area of steel, assumptions have to be

made whether the section is tension or compression controlled, and regarding

the distance between the resultant compression and tension forces along the slab

section (jd). In this example, tension-controlled section will be

assumed so the reduction factor is equal to 0.9, and jd will be taken equal to 0.95d.

The assumptions will be verified once the area of steel in finalized.

is equal to 0.9, and jd will be taken equal to 0.95d.

The assumptions will be verified once the area of steel in finalized.

Therefore, the assumption that section is

tension-controlled is valid.

ACI 318-14 (24.4.3.2)

ACI 318-14 (24.4.3.2)

Since column strip has

5 ribs à provide 10 - #6 bars (2

bars/ rib):

Based on the procedures outlined above, values for all

span locations are given in Table 3.

|

Table 3 - Required Slab Reinforcement for

Flexure [Equivalent Frame Method (EFM)]

|

|

Span Location

|

Mu

(ft-kips)

|

b

(in.)

|

d (in.)

|

As Req’d for flexure (in.2)

|

Min As (in.2)

|

Reinforcement Provided

|

As Prov. for flexure (in.2)

|

|

End Span

|

|

Column Strip

|

Exterior Negative

|

335.1

|

198

|

15.88

|

4.74

|

5.18

|

14-#6 * **

|

6.16

|

|

Positive (5 ribs)

|

378.0

|

198

|

15.81

|

5.38

|

2.85

|

10-#7

(2 bars / rib)

|

6.00

|

|

Interior Negative

|

905.9

|

198

|

15.88

|

13.05

|

5.18

|

30-#6

|

13.20

|

|

Middle Strip

|

Exterior Negative

|

0.0

|

198

|

15.88

|

0.0

|

5.18

|

14-#6 * **

|

6.16

|

|

Positive (6 ribs)

|

252.0

|

198

|

15.88

|

3.56

|

2.85

|

12-#6

(2 bars / rib)

|

5.28

|

|

Interior Negative

|

302.0

|

198

|

15.88

|

4.27

|

5.18

|

14-#6 * **

|

6.16

|

|

Interior Span

|

|

Column Strip

|

Positive (5 ribs)

|

182.6

|

198

|

15.88

|

2.57

|

2.85

|

10-#6 *

(2 bars / rib)

|

4.40

|

|

Middle Strip

|

Positive (6 ribs)

|

121.8

|

198

|

15.88

|

1.71

|

2.85

|

12-#6 *

(2 bars / rib)

|

5.28

|

|

* Design governed by minimum reinforcement.

** Number of bars governed by maximum allowable spacing.

|

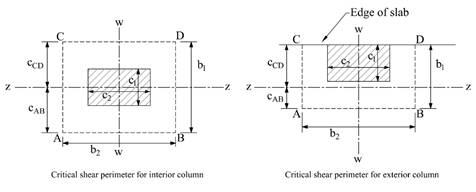

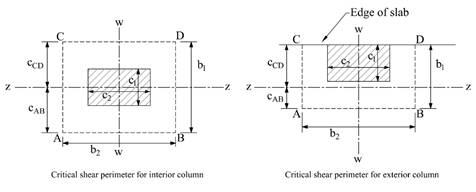

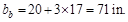

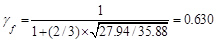

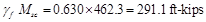

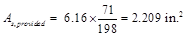

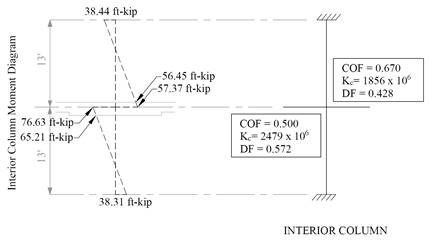

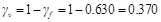

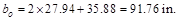

b. Calculate additional slab reinforcement at columns

for moment transfer between slab and column by flexure

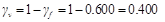

The factored slab moment resisted by the column (γf

Msc) shall be assumed to be transferred by flexure.

Concentration of reinforcement over the column by closer spacing or additional

reinforcement shall be used to resist this moment. The fraction of slab moment

not calculated to be resisted by flexure shall be assumed to be resisted by

eccentricity of shear. ACI 318-14 (8.4.2.3)

Portion of the unbalanced moment transferred by

flexure is γf Msc ACI

318-14 (8.4.2.3.1)

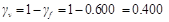

Where

ACI

318-14 (8.4.2.3.2)

ACI

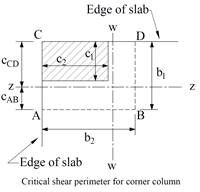

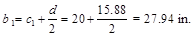

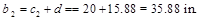

318-14 (8.4.2.3.2)

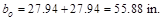

b1

= Dimension of the critical section bo

measured in the direction of the span for which

moments are determined in ACI 318, Chapter 8 (see Figure 14).

b2

= Dimension of the critical section  measured in the direction perpendicular to

measured in the direction perpendicular to  in ACI 318, Chapter 8 (see Figure 14).

in ACI 318, Chapter 8 (see Figure 14).

ACI

318-14 (8.4.2.3.3)

ACI

318-14 (8.4.2.3.3)

Figure 14 – Critical

Shear Perimeters for Columns

For exterior support:

Using the same procedure in 2.1.6.a, the required area

of steel:

However, the area of steel provided to resist the

flexural moment within the effective slab width bb:

Then, the required additional reinforcement at

exterior column for moment transfer between slab and column:

Provide 5 - #6 additional bars with As

= 2.20 in.2

Based on the procedure outlined above, values for all

supports are given in Table 4.

|

Table 4 - Additional Slab Reinforcement

required for moment transfer between slab and column (EFM)

|

|

Span Location

|

Msc*

(ft-kips)

|

γf

|

γf Msc

(ft-kips)

|

Effective slab

width, bb

(in.)

|

d

(in.)

|

As req’d

within bb

(in.2)

|

As prov. For

flexure within bb

(in.2)

|

Add’l

Reinf.

|

|

End Span

|

|

Column Strip

|

Exterior Negative

|

462.3

|

0.630

|

291

|

71

|

15.88

|

4.184

|

2.209

|

5-#6

|

|

Interior Negative

|

133.4

|

0.600

|

80.4

|

71

|

15.88

|

2.029

|

4.733

|

-

|

|

*Msc is taken at the

centerline of the support in Equivalent Frame Method solution.

|

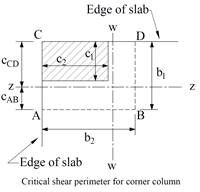

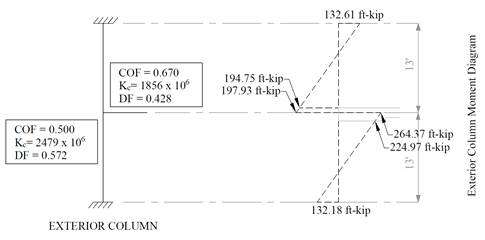

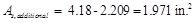

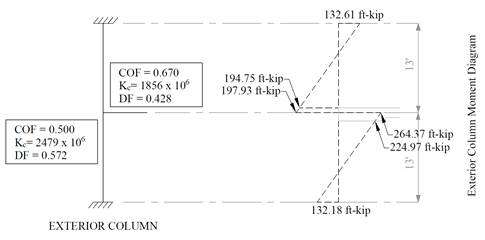

The unbalanced moment from the slab-beams at the

supports of the equivalent frame are distributed to the support columns above

and below the slab-beam in proportion to the relative stiffness of the support

columns. Referring to Figure 13, the unbalanced moment at the exterior and

interior joints are:

Exterior Joint = +462.3 ft-kips

Joint 2= -1381.5 + 1247.5 = -134 ft-kips

The stiffness and carry-over factors of the actual

columns and the distribution of the unbalanced slab moments (Msc)

to the exterior and interior columns are shown in Figure 14.

Figure 15 -

Column Moments (Unbalanced Moments from Slab-Beam)

In summary:

For Top column: For

Bottom column:

Mcol,Exterior= 194.75 ft-kips Mcol,Exterior=

224.97 ft-kips

Mcol,Interior = 56.45

ft-kips Mcol,Interior = 65.21

ft-kips

The moments determined above are combined with the

factored axial loads (for each story) and factored moments in the transverse

direction for design of column sections. The moment values at the face of

interior, exterior, and corner columns from the unbalanced moment values are

shown in the following table.

|

Table 5 – Factored Moments in Columns

|

|

Mu

kips-ft

|

Column Location

|

|

Interior

|

Exterior

|

Corner

|

|

Mux

|

65.21

|

224.97

|

224.97

|

|

Muy

|

65.21

|

65.21

|

224.97

|

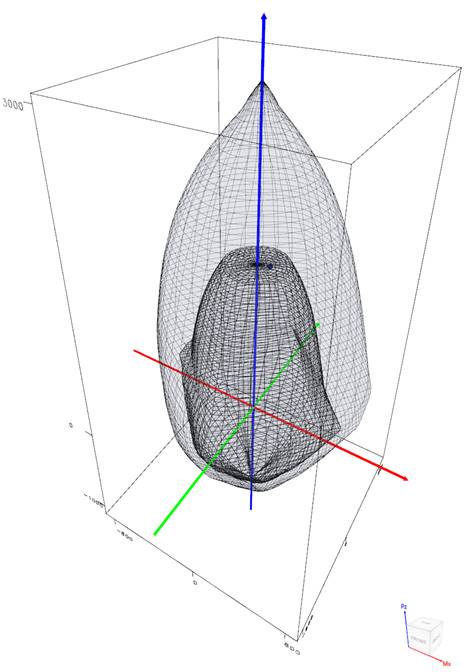

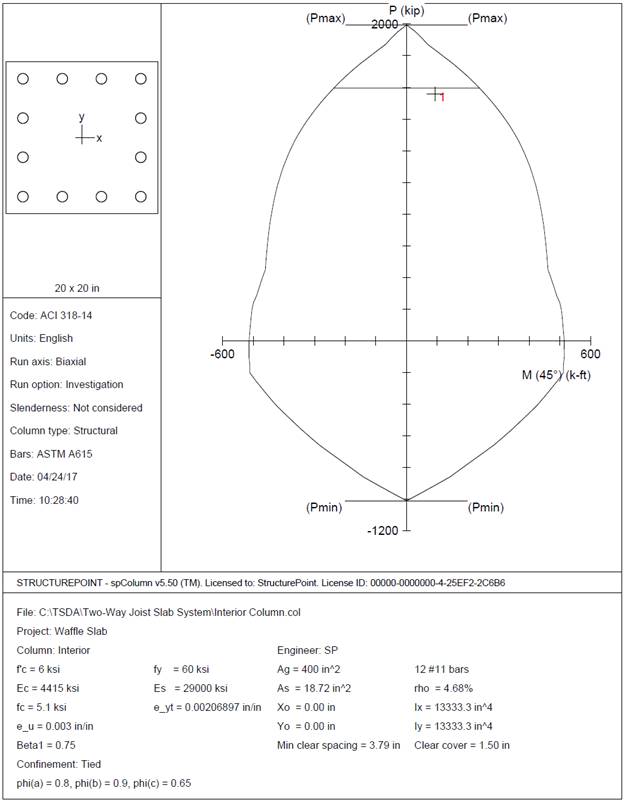

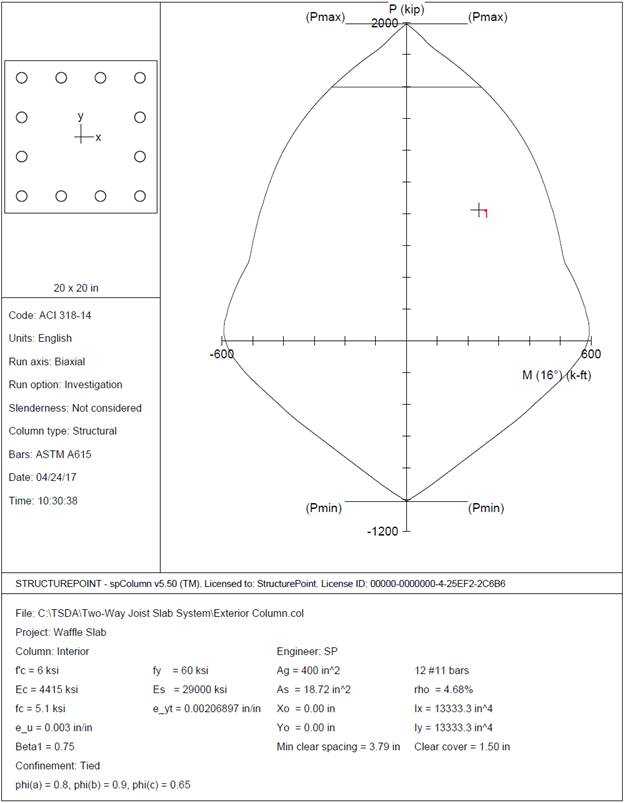

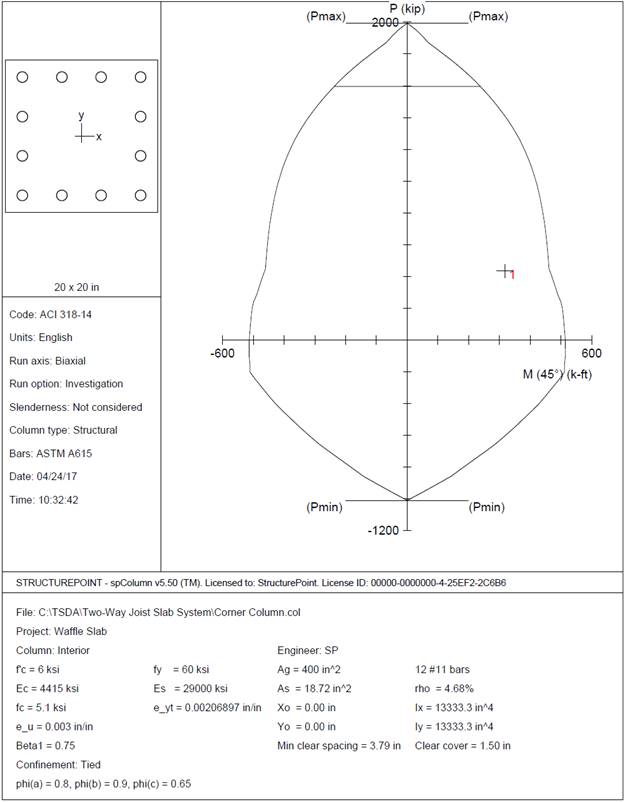

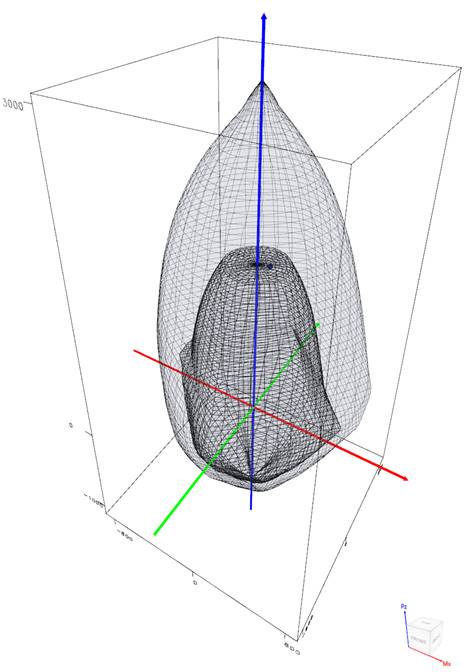

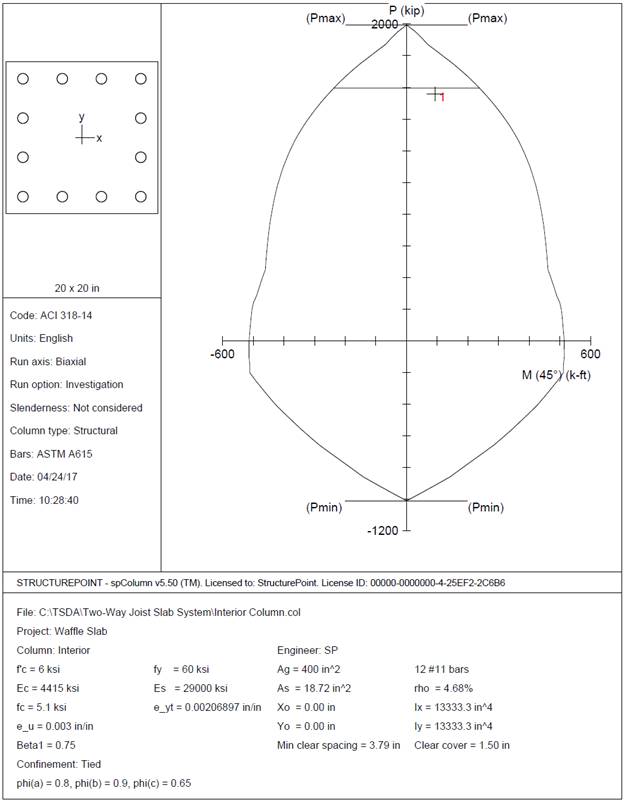

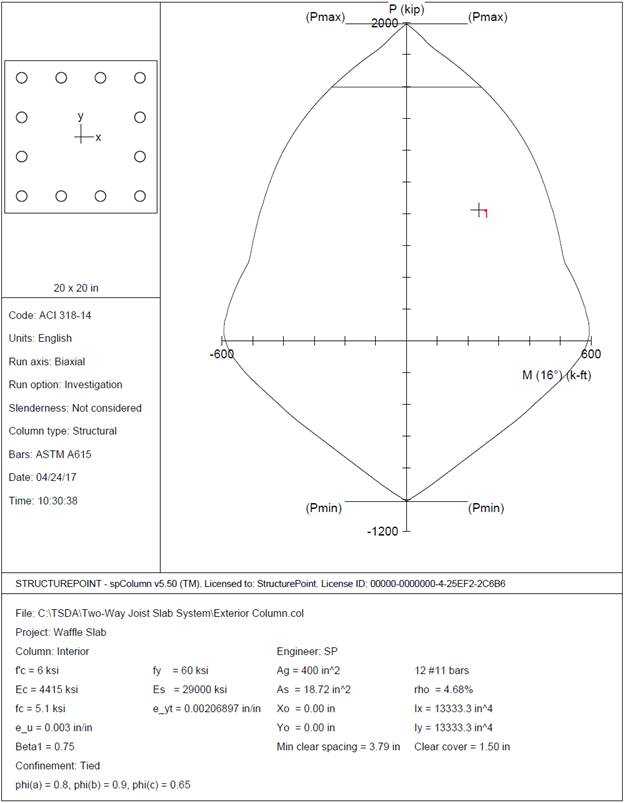

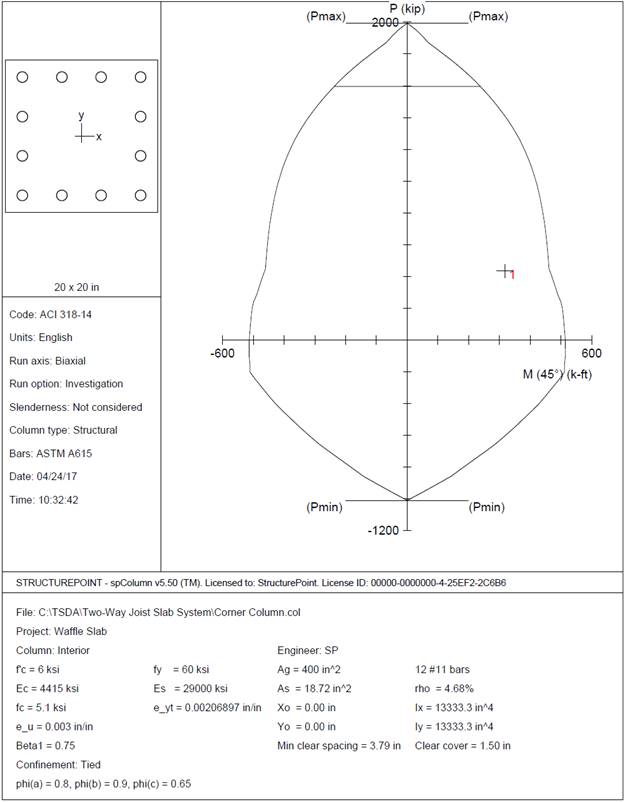

This section includes the design of

interior, edge, and corner columns using spColumn

software. The preliminary dimensions for these columns were calculated

previously in section one. The reduction of live load per ASCE 7-10

will be ignored in this example. However, the detailed procedure to calculate

the reduced live loads is explained in the “wide-Module

Joist System” example.

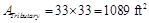

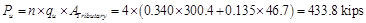

Interior Column:

Assume 4 story building

Tributary

area for interior column for live load, superimposed dead load, and self-weight

of the slab is

Tributary

area for interior column for self-weight of additional slab thickness due to

the presence of the drop panel is

Assuming five story

building

Mu,x = 65.21 ft-kips (see the previous Table)

Mu,y = 65.21 ft-kips (see the

previous Table)

Edge (Exterior) Column:

Tributary area for exterior

column for live load, superimposed dead load, and self-weight of the slab is

Tributary area for exterior

column for self-weight of additional slab thickness due to the presence of the

drop panel is

Mu,x = 224.97 ft-kips (see the previous Table)

Mu,y = 65.21 ft-kips (see the

previous Table)

Corner Column:

Tributary area for corner

column for live load, superimposed dead load, and self-weight of the slab is

Tributary area for corner

column for self-weight of additional slab thickness due to the presence of the

drop panel is

Mu,x = 224.97 ft-kips (see the previous Table)

Mu,y = 224.97 ft-kips (see the

previous Table)

Interior Column:

Edge Column:

Corner Column:

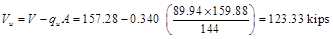

Shear strength of the slab in the vicinity

of columns/supports includes an evaluation of one-way shear (beam action) and

two-way shear (punching) in accordance with ACI 318 Chapter 22.

ACI

318-14 (22.5)

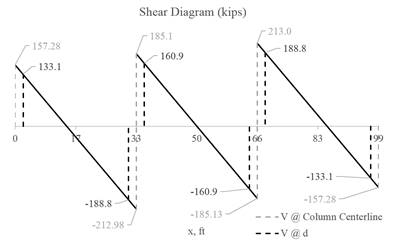

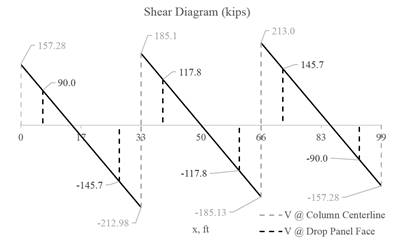

One-way

shear is critical at a distance d from the face of the column as shown

in Figure 3. Figures 17 and 19 show the factored shear forces (Vu)

at the critical sections around each column and each drop panel, respectively. In

members without shear reinforcement, the design shear capacity of the section

equals to the design shear capacity of the concrete:

ACI 318-14 (Eq. 22.5.1.1)

ACI 318-14 (Eq. 22.5.1.1)

Where:

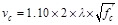

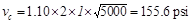

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

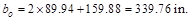

One-way shear capacity

is calculated assuming the shear cross-section area consisting of the drop

panel (if any), the ribs, and the slab portion above them, decreased by

concrete cover. For such section the equivalent shear width for single rib is

calculated from the formula:

spSlab

Software Manual (Eq. 2-13)

spSlab

Software Manual (Eq. 2-13)

Where:

b = rib width, in.

d = distance from extreme compression fiber

to tension reinforcement centroid.

for

middle span with #6 reinforcement.

for

middle span with #6 reinforcement.

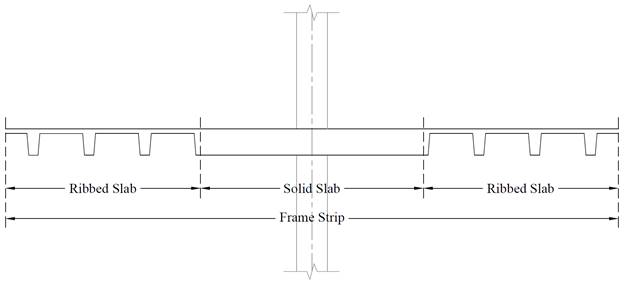

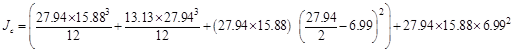

Figure 16 – Frame strip cross section (at distance d from

the face of the supporting column)

The one-way shear capacity for the ribbed slab

portions shown in Figure 16 is permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

Figure 17 – One-way shear at critical sections (at distance d

from the face of the supporting column)

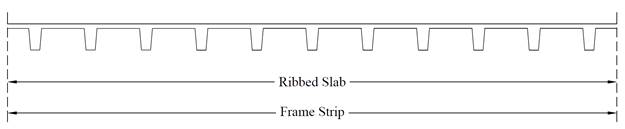

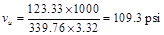

for

middle span with #6 reinforcement.

for

middle span with #6 reinforcement.

Figure 18 – Frame strip cross section (at distance d from

the face of the supporting column)

The one-way shear capacity for the ribbed slab

portions shown in Figure 15 is permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

Figure 19 – One-way shear at critical sections (at the face of

the drop panel)

ACI

318-14 (22.6)

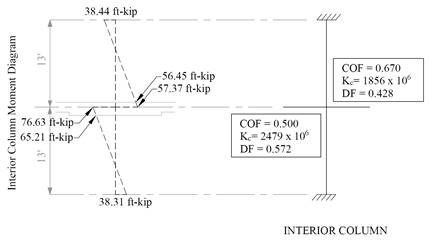

Two-way shear is critical on

a rectangular section located at d/2 away from the face of the column as

shown in Figure 14.

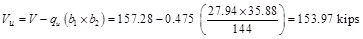

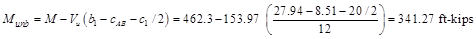

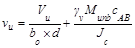

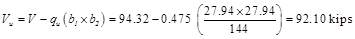

a. Exterior column:

The

factored shear force (Vu) in the critical section is computed

as the reaction at the centroid of the critical section minus the self-weight

and any superimposed surface dead and live load acting within the critical

section (d/2 away from column face).

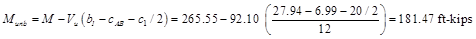

The factored

unbalanced moment used for shear transfer, Munb, is computed

as the sum of the joint moments to the left and right. Moment of the vertical

reaction with respect to the centroid of the critical section is also taken

into account.

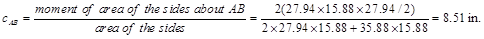

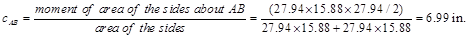

For the exterior

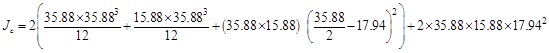

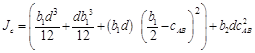

column in Figure 13, the location of the centroidal axis z-z is:

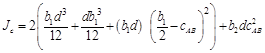

The

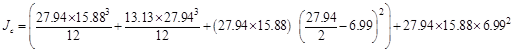

polar moment Jc of the shear perimeter is:

ACI 318-14 (Eq. 8.4.4.2.2)

ACI 318-14 (Eq. 8.4.4.2.2)

The

length of the critical perimeter for the exterior column:

The

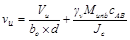

two-way shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

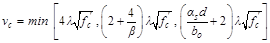

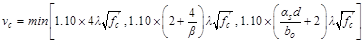

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

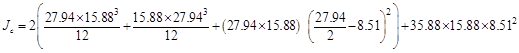

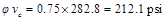

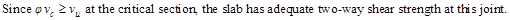

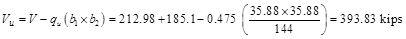

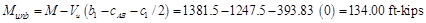

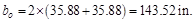

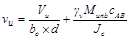

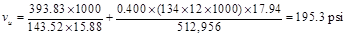

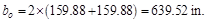

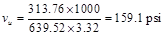

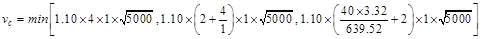

b. Interior column:

For

the interior column in Figure 13, the location of the centroidal axis z-z is:

The

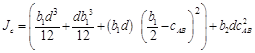

polar moment Jc of the shear perimeter is:

ACI 318-14 (Eq. 8.4.4.2.2)

ACI 318-14 (Eq. 8.4.4.2.2)

The

length of the critical perimeter for the interior column:

The

two-way shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

c. Corner column:

In

this example, interior equivalent frame strip was selected where it only have

exterior and interior supports (no corner supports are included in this strip).

However, the two-way shear strength of corner supports usually governs. Thus,

the two-way shear strength for the corner column in this example will be

checked for illustration purposes. The analysis procedure must be repeated for

the exterior equivalent frame strip to find the reaction and factored

unbalanced moment used for shear transfer at the centroid of the critical

section for the corner support.

For

the interior column in Figure 13, the location of the centroidal axis z-z is:

The

polar moment Jc of the shear perimeter is:

ACI 318-14 (Eq. 8.4.4.2.2)

ACI 318-14 (Eq. 8.4.4.2.2)

The

length of the critical perimeter for the corner column:

The two-way

shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

Two-way

shear is critical on a rectangular section located at d/2 away from the

face of the drop panel.

The

factored shear force (Vu) in the critical section is computed

as the reaction at the centroid of the critical section minus the self-weight

and any superimposed surface dead and live load acting within the critical

section (d/2 away from column face).

Note: For simplicity, it

is conservative to deduct only the self-weight of the slab and joists in the

critical section from the shear reaction in punching shear calculations. This

approach is also adopted in the spSlab program for the punching shear check

around the drop panels.

a. Exterior drop panel:

d that is used in the

calculation of vu is given by (see Figure 20):

spSlab

Software Manual (Eq. 2-14)

spSlab

Software Manual (Eq. 2-14)

Figure 20 – Equivalent thickness based on shear area calculation

The

length of the critical perimeter for the exterior drop panel:

The

two-way shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

The two-way shear capacity for the ribbed slab is

permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

In waffle slab design where the

drop panels create a large critical shear perimeter, the factor (bo/d)

has limited contribution and is traditionally neglected for simplicity and conservatism.

This approach is adopted in this calculation and

in the spSlab program (spSlab software manual, Eq. 2-46).

The two-way shear capacity for the ribbed slab is

permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

b. Interior drop panel:

The

length of the critical perimeter for the interior drop panel:

The

two-way shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

The two-way shear capacity for the ribbed slab is

permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

spSlab Software Manual (Eq. 2-46)

spSlab Software Manual (Eq. 2-46)

c. Corner drop panel:

The

length of the critical perimeter for the corner drop panel:

The

two-way shear stress (vu) can then be calculated as:

ACI 318-14 (R.8.4.4.2.3)

ACI 318-14 (R.8.4.4.2.3)

The two-way shear capacity for the ribbed slab is

permitted to be increased by 10%. ACI 318-14 (9.8.1.5)

ACI 318-14 (Table 22.6.5.2)

ACI 318-14 (Table 22.6.5.2)

spSlab Software Manual (Eq. 2-46)

spSlab Software Manual (Eq. 2-46)

To mitigate the deficiency in

two-way shear capacity an evaluation of possible options is required:

1.

Increase the

thickness of the slab system

2.

Increasing the

dimensions of the drop panels (length and/or width)

3.

Increasing the

concrete strength

4.

Reduction of the

applied loads

5.

Reduction of the

panel spans

6.

Using less

conservative punching shear allowable (gain of 5-10%)

7.

Refine the

deduction of drop panel weight from the shear reaction (gain of 2-5%)

This example will be continued without the

required modification discussed above to continue the illustration of the

analysis and design procedure.

Since the slab thickness was

selected to meet the minimum slab thickness tables in ACI 318-14, the

deflection calculations of immediate and time-dependent deflections are not required.

They are shown below for illustration purposes and comparison with spSlab

software results.

The

calculation of deflections for two-way slabs is challenging even if linear

elastic behavior can be assumed. Elastic analysis for three service load levels

(D, D + Lsustained, D+LFull) is used to obtain immediate

deflections of the two-way slab in this example. However, other procedures may

be used if they result in predictions of deflection in reasonable agreement

with the results of comprehensive tests. ACI

318-14 (24.2.3)

The

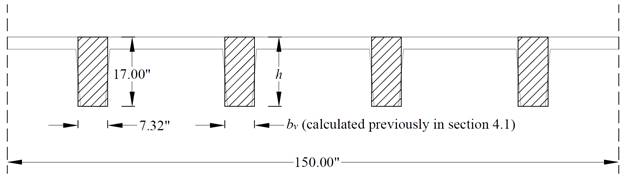

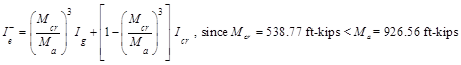

effective moment of inertia (Ie) is used to account for the

cracking effect on the flexural stiffness of the slab. Ie for

uncracked section (Mcr > Ma) is equal to Ig.

When the section is cracked (Mcr < Ma), then

the following equation should be used:

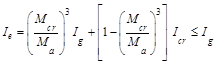

ACI 318-14 (Eq. 24.2.3.5a)

ACI 318-14 (Eq. 24.2.3.5a)

Where:

Ma = Maximum moment in member due to service loads at stage deflection is

calculated.

The

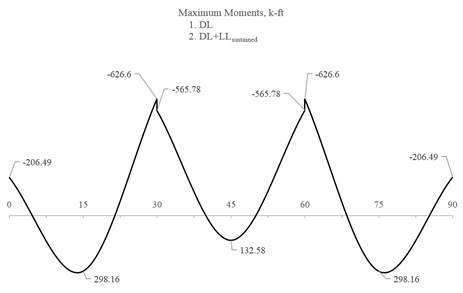

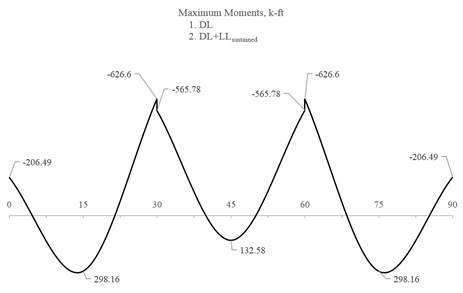

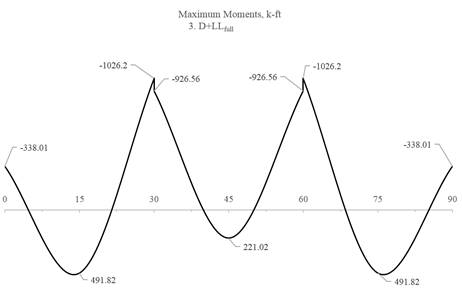

values of the maximum moments for the three service load levels are calculated

from structural analysis as shown previously in this document. These moments are

shown in Figure 17.

Figure 21 – Maximum Moments for the Three Service Load Levels

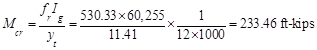

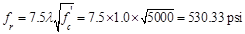

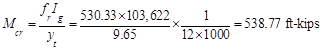

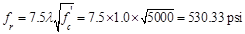

For positive moment (midspan) section:

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 19.2.3.1)

ACI

318-14 (Eq. 19.2.3.1)

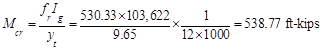

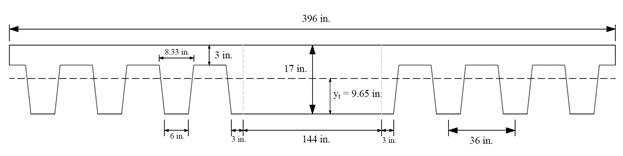

yt = Distance from centroidal axis

of gross section, neglecting reinforcement, to tension face, in.

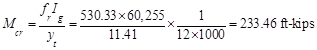

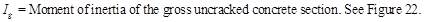

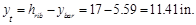

Figure 22 – Equivalent gross section for one rib - positive moment

section

PCA Notes on ACI 318-11 (9.5.2.2)

PCA Notes on ACI 318-11 (9.5.2.2)

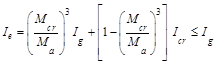

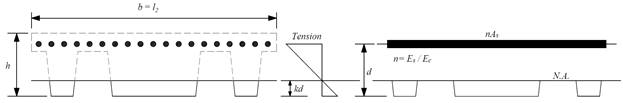

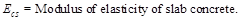

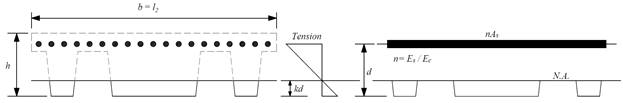

As

calculated previously, the positive reinforcement for the middle span frame

strip is 22 #6 bars located at 1.125 in. along the section from the bottom of

the slab. Figure 23 shows all the parameters needed to calculate the moment of

inertia of the cracked section transformed to concrete at midspan.

Figure 23 – Cracked Transformed Section - positive moment section

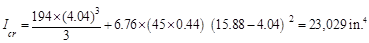

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

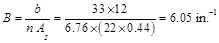

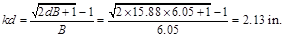

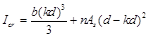

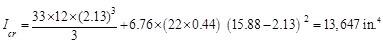

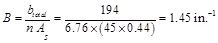

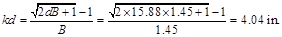

PCA Notes on ACI 318-11 (Table 10-2)

PCA Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA Notes on ACI

318-11 (Table 10-2)

PCA Notes on ACI

318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

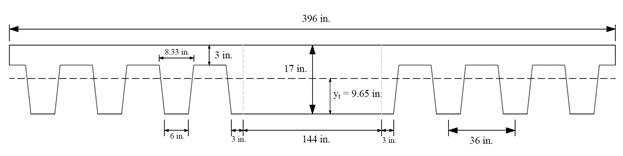

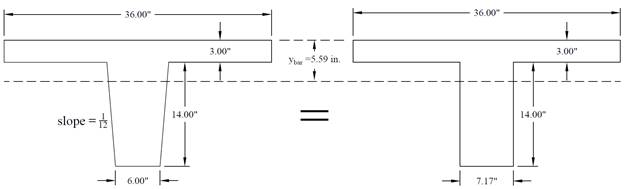

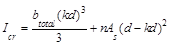

For negative moment section (near the interior

support of the end span):

The

negative reinforcement for the end span frame strip near the interior support

is 45 #6 bars located at 1.125 in. along the section from the top of the slab.

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 24.2.3.5b)

ACI

318-14 (Eq. 19.2.3.1)

ACI

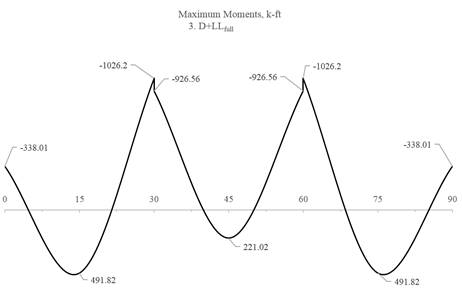

318-14 (Eq. 19.2.3.1)

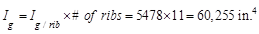

Note: A lower value of Ig

(60,255 in.4) excluding the drop panel is conservatively adopted in

calculating waffle slab deflection by the spSlab software.

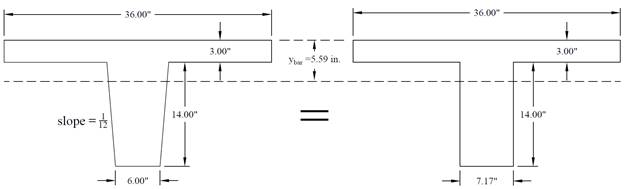

Figure 24 – Gross section – negative moment section

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

PCA Notes on ACI 318-11 (Table 10-2)

PCA Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA Notes on

ACI 318-11 (Table 10-2)

PCA Notes on

ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

PCA

Notes on ACI 318-11 (Table 10-2)

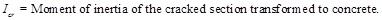

Note: A lower value of Icr

(18,722 in.4) excluding the drop panel is conservatively adopted in

calculating waffle slab deflection by the spSlab software.

Figure 25 – Cracked transformed section - negative moment section

The

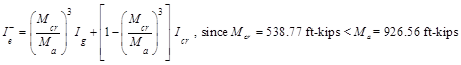

effective moment of inertia procedure described in the Code is considered

sufficiently accurate to estimate deflections. The effective moment of inertia,

Ie, was developed to provide a transition between the upper

and lower bounds of Ig and Icr as a

function of the ratio Mcr/Ma. For conventionally

reinforced (nonprestressed) members, the effective moment of inertia, Ie,

shall be calculated by Eq. (24.2.3.5a) unless obtained by a more comprehensive

analysis.

Ie

shall be permitted to be taken as the

value obtained from Eq. (24.2.3.5a) at midspan for simple and continuous spans,

and at the support for cantilevers. ACI

318-14 (24.2.3.7)

For

continuous one-way slabs and beams. Ie shall be permitted to

be taken as the average of values obtained from Eq. (24.2.3.5a) for the

critical positive and negative moment sections. ACI

318-14 (24.2.3.6)

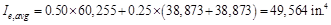

For the middle span

(span with two ends continuous) with service load level (D+LLfull):

ACI

318-14 (24.2.3.5a)

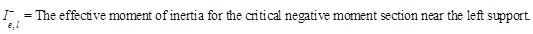

Where Ie-

is the effective moment of inertia for the critical negative moment

section (near the support).

Where Ie+

is the effective moment of inertia for the critical positive moment section

(midspan).

Since

midspan stiffness (including the effect of cracking) has a dominant effect on

deflections, midspan section is heavily represented in calculation of Ie

and this is considered satisfactory in approximate deflection calculations.

Both the midspan stiffness (Ie+) and averaged span

stiffness (Ie,avg) can be used in the calculation of

immediate (instantaneous) deflection.

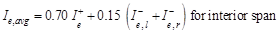

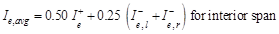

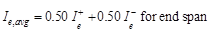

The averaged effective

moment of inertia (Ie,avg) is given by:

PCA Notes on ACI 318-11 (9.5.2.4(2))

PCA Notes on ACI 318-11 (9.5.2.4(2))

PCA

Notes on ACI 318-11 (9.5.2.4(1))

PCA

Notes on ACI 318-11 (9.5.2.4(1))

However,

these expressions lead to improved results only for continuous prismatic

members. The drop panels in this example result in non-prismatic members

and the following expressions are recommended according to ACI 318-89:

ACI

435R-95 (2.14)

ACI

435R-95 (2.14)

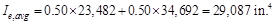

For the middle span

(span with two ends continuous) with service load level (D+LLfull):

ACI

435R-95 (2.14)

ACI

435R-95 (2.14)

For the end span (span

with one end continuous) with service load level (D+LLfull):

Where:

Note: The prismatic member equations

excluding the effect of the drop panel are conservatively adopted in

calculating waffle slab deflection by spSlab.

Table

6 provides a summary of the required parameters and calculated values needed

for deflections for exterior and interior spans.

|

Table

6 – Averaged Effective Moment of Inertia Calculations

|

|

For Frame

Strip

|

|

Span

|

zone

|

Ig,

in.4

|

Icr,

in.4

|

Ma,

kips-ft

|

Mcr,

k-ft

|

Ie,

in.4

|

Ie,avg,

in.4

|

|

D

|

D +

LLSus

|

D +

Lfull

|

D

|

D +

LLSus

|

D +

Lfull

|

D

|

D +

LLSus

|

D +

Lfull

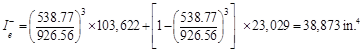

|

|

Ext

|

Left

|

103622

|

15505

|

206.5

|

206.5

|

338.0

|

539

|

103622

|

103622

|

103622

|

62612

|

62612

|

29087

|

|

Midspan

|

60255

|

15603

|

298.2

|

298.2

|

491.8

|

276

|

50964

|

50964

|

23482

|

|

Right

|

103622

|

23029

|

626.6

|

626.6

|

1026.2

|

539

|

74259

|

74259

|

34692

|

|

Int

|

Left

|

103622

|

23029

|

565.8

|

565.8

|

926.6

|

539

|

92620

|

92620

|

38873

|

76437

|

76437

|

49564

|

|

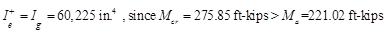

Mid

|

60255

|

13647

|

132.6

|

132.6

|

221.0

|

276

|

60255

|

60255

|

60255

|

|

Right

|

103622

|

23029

|

565.8

|

565.8

|

926.6

|

539

|

92620

|

92620

|

38873

|

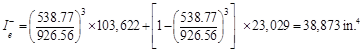

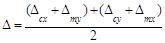

Deflections

in two-way slab systems shall be calculated taking into account size and shape

of the panel, conditions of support, and nature of restraints at the panel

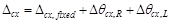

edges. For immediate deflections in two-way slab systems, the midpanel deflection is computed as the sum of deflection at

midspan of the column strip or column line in one direction (Δcx

or Δcy) and deflection at midspan of the middle strip in

the orthogonal direction (Δmx or Δmy).

Figure 26 shows the deflection computation for a rectangular panel. The average

Δ for panels that have different properties in the two direction is

calculated as follows:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 8)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 8)

Figure 26 – Deflection Computation for a rectangular Panel

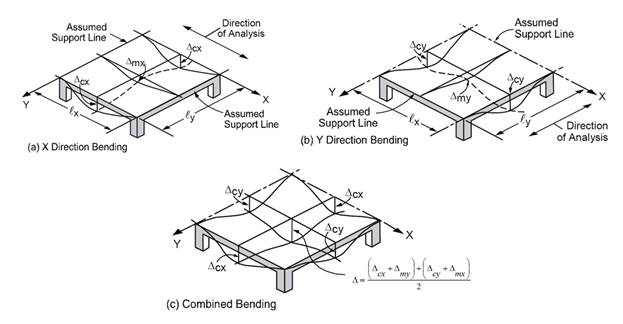

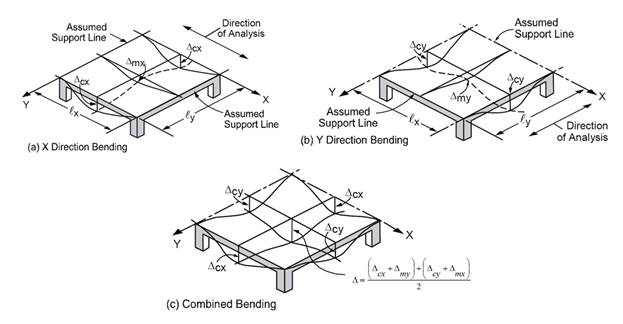

To calculate each

term of the previous equation, the following procedure should be used. Figure 27

shows the procedure of calculating the term Δcx. Same

procedure can be used to find the other terms.

Figure 27 –Δcx calculation procedure

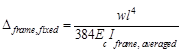

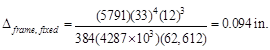

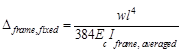

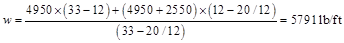

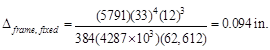

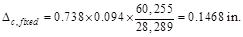

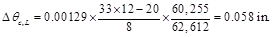

For end span - service

dead load case:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 10)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 10)

Where:

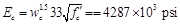

ACI

318-14 (19.2.2.1.a)

ACI

318-14 (19.2.2.1.a)

Iframe,averaged =

The averaged effective moment of inertia (Ie,avg)

for the frame strip for service dead load case from Table 6 = 62,612 in.4

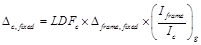

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 11)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 11)

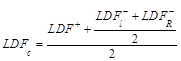

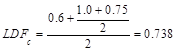

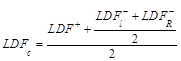

LDFc is the load distribution factor for the column strip.

The load distribution factor for the column strip can be found from the

following equation:

spSlab Software Manual (Eq. 2-114)

spSlab Software Manual (Eq. 2-114)

And the load

distribution factor for the middle strip can be found from the following

equation:

spSlab Software Manual (Eq. 2-115)

spSlab Software Manual (Eq. 2-115)

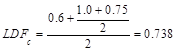

Taking

for example the end span where highest deflections are expected, the LDF for

exterior negative region (LDFL¯), interior negative region (LDFR¯), and

positive region (LDFL+)

are 1.00, 0.75, and 0.60, respectively (From Table

2 of this document). Thus, the load distribution factor for the column strip

for the end span is given by:

Ic,g = The gross moment of inertia (Ig) for

the column strip for service dead load = 28,289 in.4

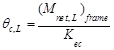

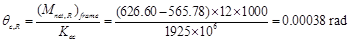

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 12)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 12)

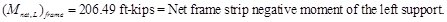

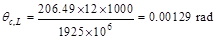

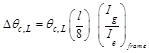

Where:

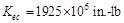

Kec = effective column stiffness = 1925

x 106 in.-lb (calculated previously).

PCA

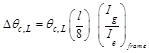

Notes on ACI 318-11 (9.5.3.4 Eq. 14)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 14)

Where:

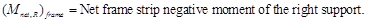

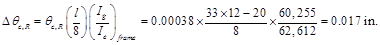

Where

Where:

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 9)

PCA

Notes on ACI 318-11 (9.5.3.4 Eq. 9)

Following

the same procedure, Δmx can be calculated for the middle

strip. This procedure is repeated for the equivalent frame in the orthogonal

direction to obtain Δcy, and Δmy

for the end and middle spans for the other load levels (D+LLsus

and D+LLfull).

Since

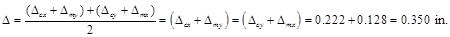

this example has square panels, Δcx = Δcy=

0.222 in. and Δmx = Δmy=

0.128 in.

The

average Δ for the corner panel is calculated as follows:

The calculated deflection can now be compared with

the applicable limits from the governing standards or project specified limits

and requirements. Optimization for further savings in materials or construction

costs can be now made based on permissible deflections in lieu of accepting the

minimum values stipulated in the standards to avoid deflection calculations.