Code

Building

Code Requirements for Structural Concrete (ACI 318-14) and Commentary (ACI

318R-14)

Minimum

Design Loads for Buildings and Other Structures (ASCE/SEI 7-10)

International

Code Council, 2012 International Building Code, Washington, D.C., 2012

References

Notes on

ACI 318-11 Building Code Requirements for Structural Concrete, Twelfth Edition,

2013 Portland Cement Association.

Concrete

Floor Systems (Guide to Estimating and Economizing), Second Edition, 2002 David

A. Fanella

Simplified

Design of Reinforced Concrete Buildings, Fourth Edition, 2011 Mahmoud E. Kamara

and Lawrence C. Novak

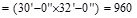

Design Data

Floor-to-Floor

Height = 12 ft (provided by architectural drawings)

wc

= 150 pcf

fc’

= 5,000 psi

fy = 60,000 psi (For flexural reinforcement)

fyt = 60,000 psi (For shear and torsional reinforcement)

Superimposed dead load, SDL = 20 psf framed

partitions, wood studs plaster 2 sides

ASCE/SEI 7-10 (Table C3-1)

Typical

Floor Level, Live load, Lo = 80 psf (Office

building) ASCE/SEI 7-10 (Table

4-1)

Roof Live

Load, Lo = 20 psf (Ordinary flat

roofs) ASCE/SEI

7-10 (Table 4-1)

Required

fire resistance rating = 2 hours

Solution

In this example

deflection will be calculated and checked to satisfy project deflection limits.

Minimum member thickness and depths from ACI 318-14 will be used for

preliminary sizing.

a. One-way Slab

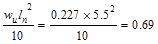

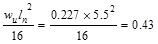

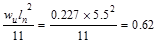

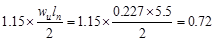

Using minimum thickness for solid one-way slabs in Table

7.3.1.1 for the solid slab spanning between the ribs.

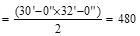

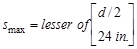

End Spans:  in

ACI 318-14 (Table 7.3.1.1)

in

ACI 318-14 (Table 7.3.1.1)

Interior Spans:  in

ACI 318-14 (Table 7.3.1.1)

in

ACI 318-14 (Table 7.3.1.1)

The minimum slab thickness for wide-module

joists for 2-hour fire rating is 4.6 in.

IBC 2012 (Table

720.1(3))

Therefore, select a slab thickness of 5 in. for all spans.

b. One-way Joist

The wide-module joist systems do not meet

the limitations of ACI 318-14, 9.8.1.1 through 9.8.1.4.

Therefore, the structural members of this type of joist construction shall be

designed with standard provisions for slabs and beams.

ACI 318-14 (9.8.1.8)

Using minimum thickness for

non-prestressed beams in Table 9.3.1.1. For the ribs (part

of the joists) supporting the solid slab.

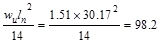

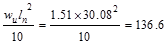

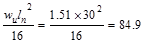

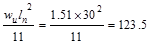

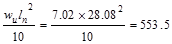

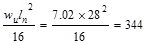

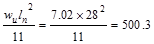

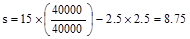

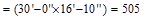

End Span:  in

(governs) ACI 318-14 (Table

9.3.1.1)

in

(governs) ACI 318-14 (Table

9.3.1.1)

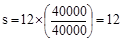

Interior Span:  in

ACI 318-14 (Table 9.3.1.1)

in

ACI 318-14 (Table 9.3.1.1)

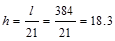

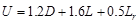

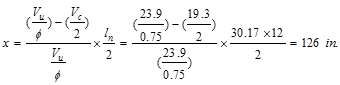

Therefore, select rib depth of 16 in. for a total

joist depth of 21 in.

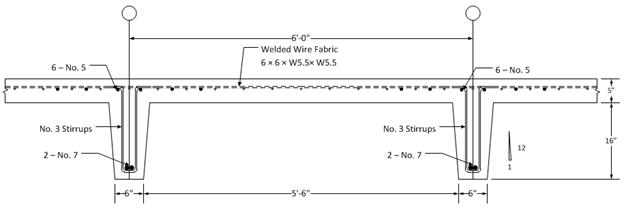

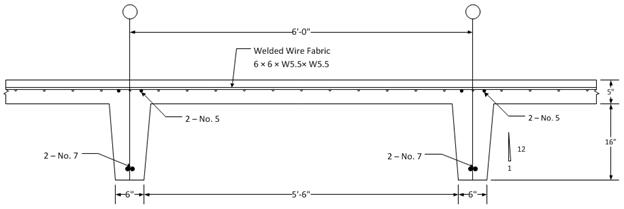

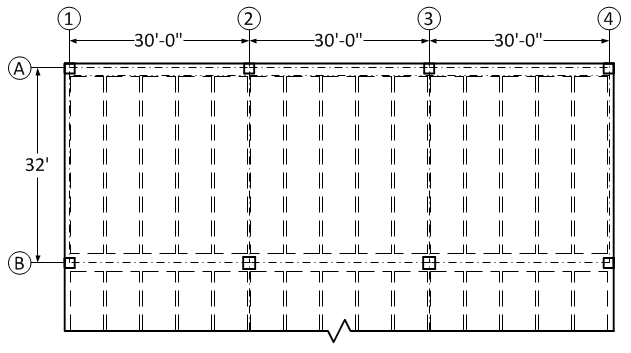

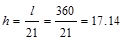

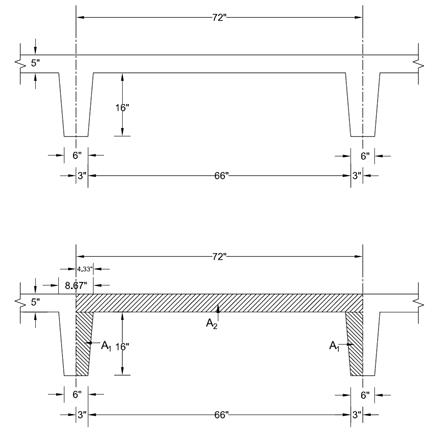

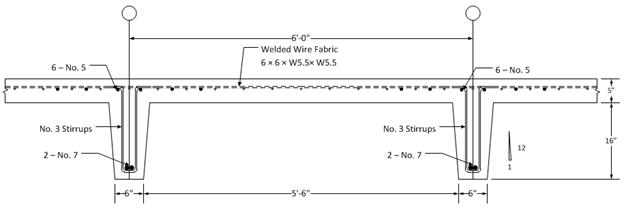

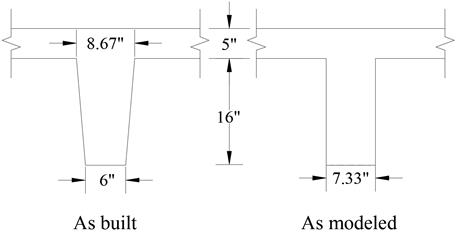

Figure 2 – Slab

and Joist Dimensions

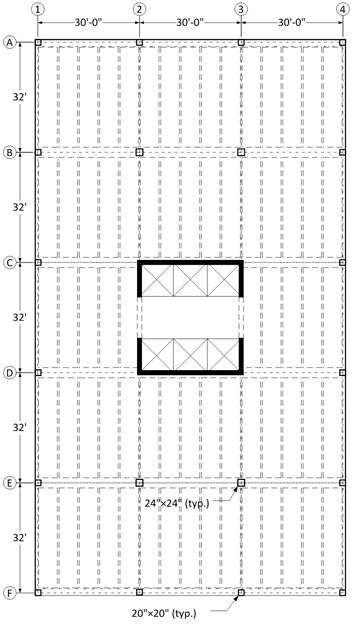

a.

Interior Columns

Select a preliminary size based on

the axial load demand. Determine interior column loads as follows:

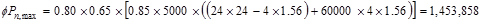

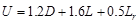

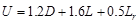

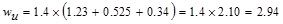

The governing load combination:  ACI

318-14 (Eq. 5.3.1b)

ACI

318-14 (Eq. 5.3.1b)

Where:

D = Dead Load; L= Live Load; Lr=

Roof Live Load

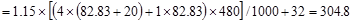

Typical Floor Level Loads

# of Floors = 4

Dead Loads, D

Self-weight

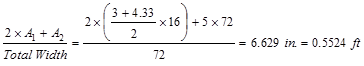

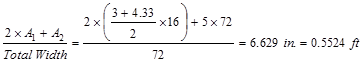

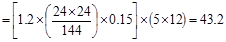

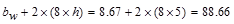

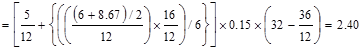

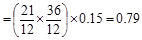

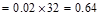

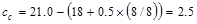

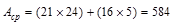

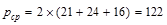

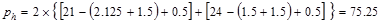

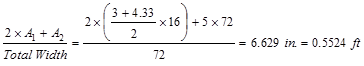

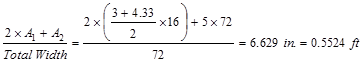

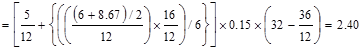

of wide-module joist system (see Figure 2):

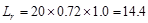

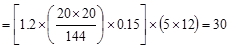

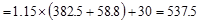

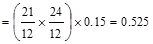

Joist average

thickness =

Weight of the

joist = 0.5524 x 150 pcf = 82.83 psf.

Superimposed dead load = 20 psf

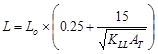

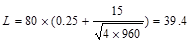

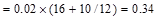

Live Load, L:

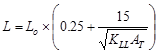

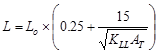

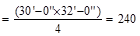

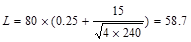

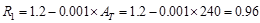

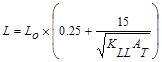

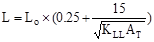

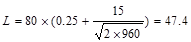

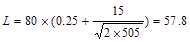

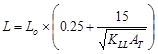

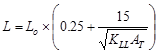

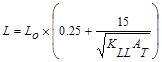

Calculate the live load reduction per ASCE/SEI 7-10

ASCE/SEI

7-10 (Eq. 4-1)

ASCE/SEI

7-10 (Eq. 4-1)

Where:

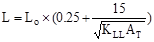

L = reduced design live load per ft2

of area supported by the member

Lo = unreduced design live load per ft2

of area supported by the member = 80 psf

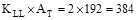

KLL = live load element

factor ASCE/SEI

7-10 (Table 4-2)

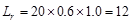

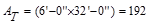

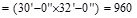

AT = tributary area  ft2

ft2

psf

psf

Which

satisfies  requirement for members supporting two or more floors.

requirement for members supporting two or more floors.

ASCE/SEI 7-10 (4.7.2)

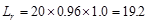

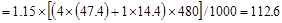

Roof Level Loads

Dead Loads, D

Self-weight

of wide-module joist system (see Figure 2):

Joist average

thickness =

Weight of the

joist = 0.5524 x 150 pcf = 82.83 psf.

No

superimposed dead load at the roof

Roof Live

Load, Lr: Calculate the roof live load reduction

;

;

ASCE/SEI

7-10 (Eq 4-2)

ASCE/SEI

7-10 (Eq 4-2)

Where:

psf

psf

since

since

ft2

ft2

ft2

ft2

for

flat roof

for

flat roof

psf

psf

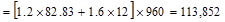

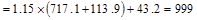

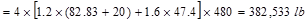

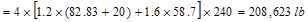

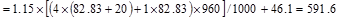

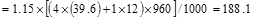

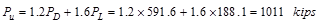

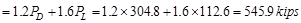

Total Factored Load on 1st

story interior column (@ 1st interior support)

Total Floor Load

kips

kips

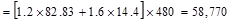

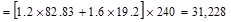

Total Roof Load lb

lb kips

kips

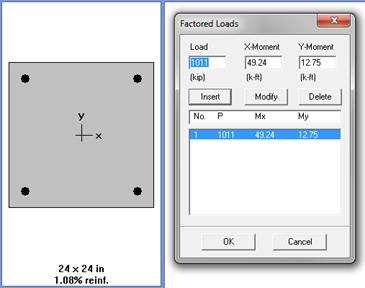

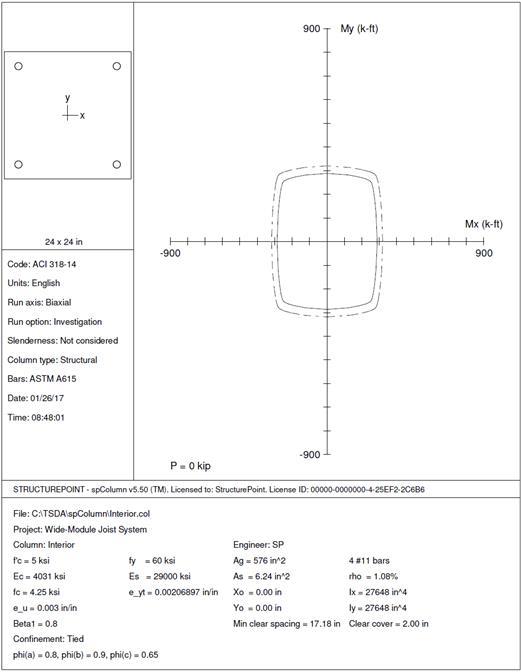

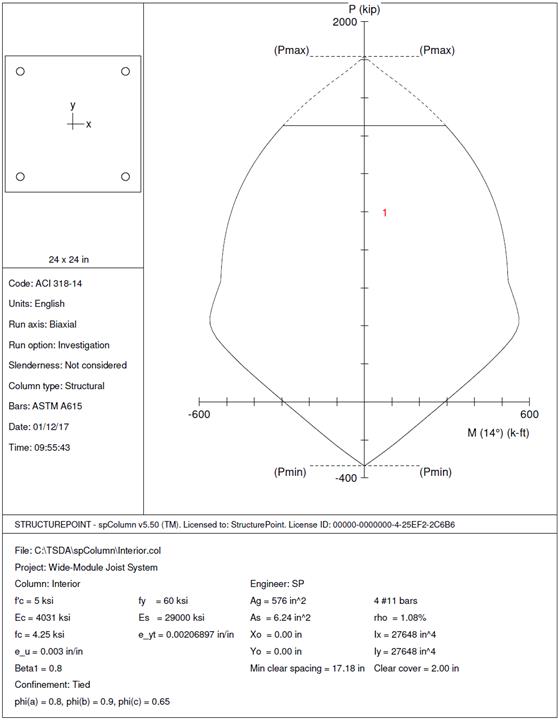

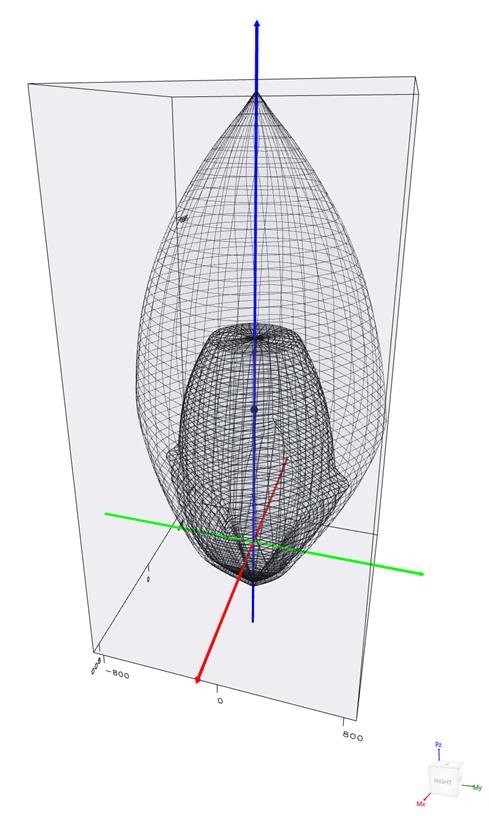

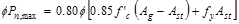

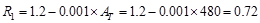

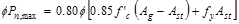

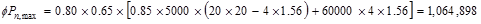

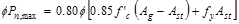

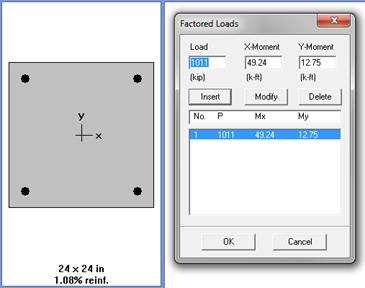

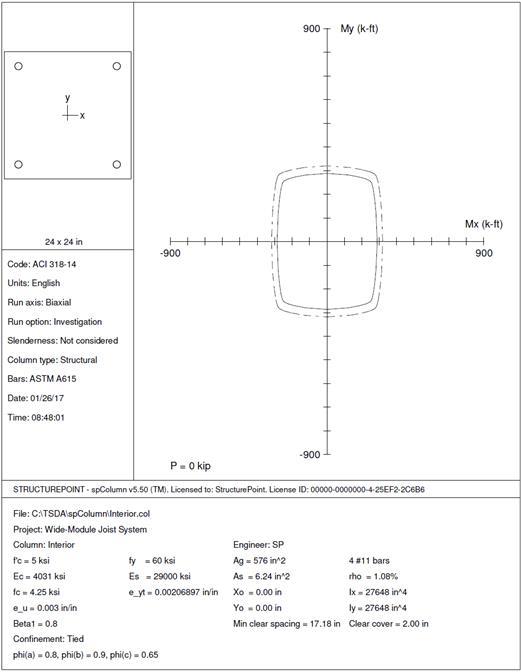

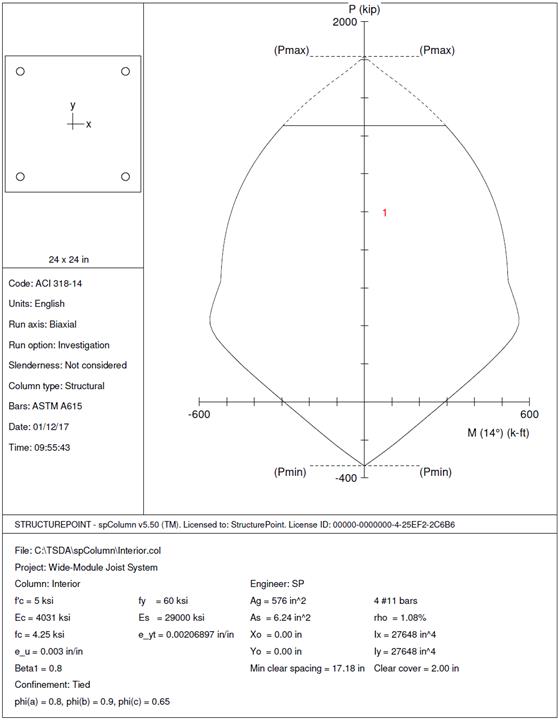

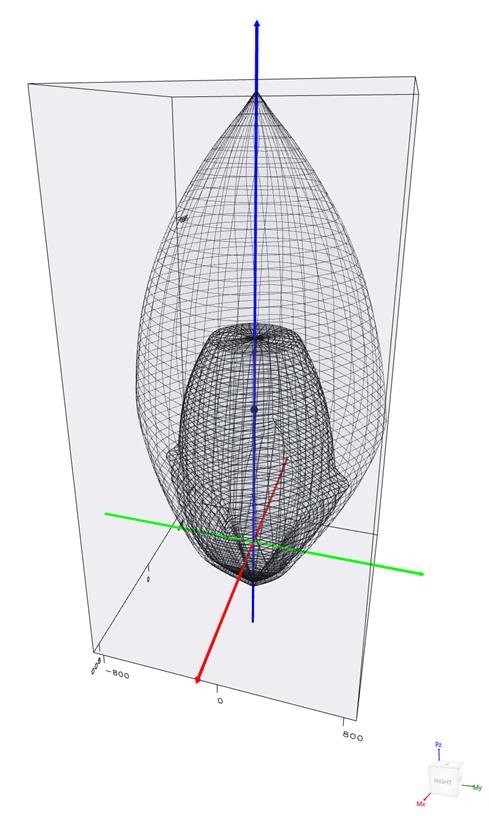

Assume 24 in square column with 4 – #

11 vertical bars with design axial strength,  of

of

ACI 318-14 (22.4.2)

ACI 318-14 (22.4.2)

lb

lb

kips

kips

Column Self-weight  kips

kips

Total Reaction @ 1st

interior support  kips

kips

kips.

kips.

Therefore, the preliminary interior

column size of 24 in. x 24 in. is adequate.

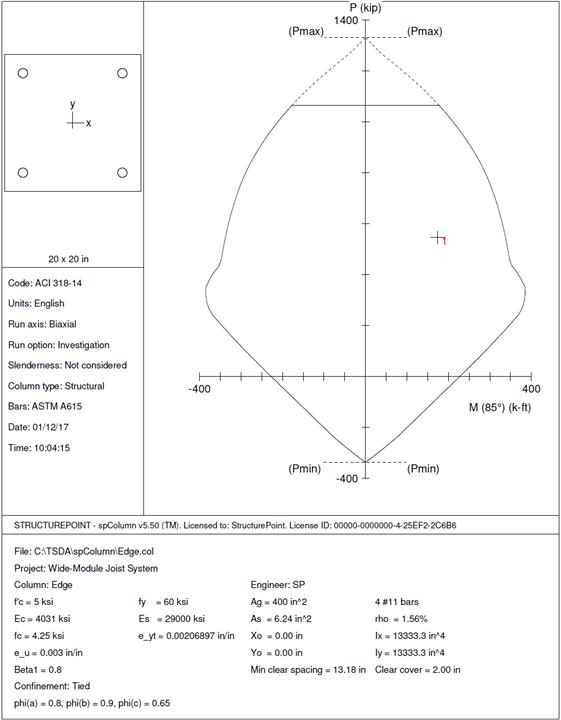

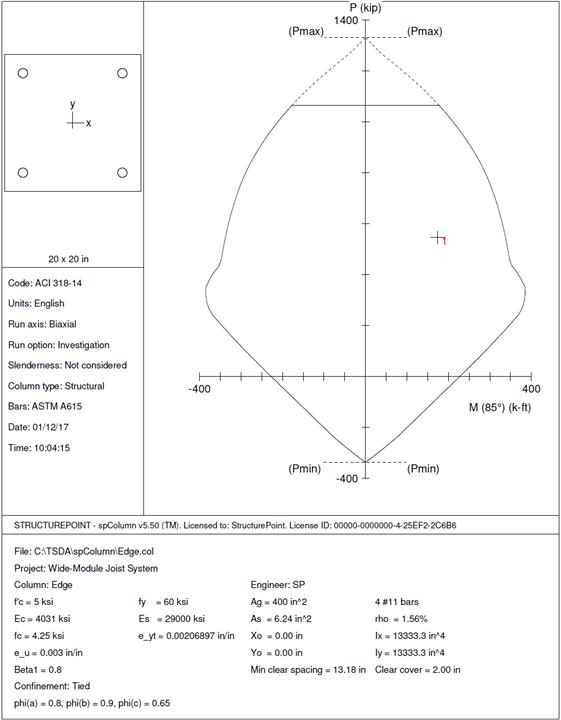

b.

Edge (Exterior) Columns

Select a preliminary size based on

the axial load demand. Therefore, the load take-down for an edge column is done

as follows:

The governing load combination:  ACI

318-14 (Eq. 5.3.1b)

ACI

318-14 (Eq. 5.3.1b)

Typical Floor Level Loads

# of Floors = 4

Dead Loads, D

Self-weight

of wide-module joist system (see Figure 2):

Weight of the

joist = 82.83 psf.

Superimposed dead load = 20 psf

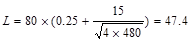

Live Load, L:

Calculate the live load reduction per ASCE/SEI 7-10

ASCE/SEI 7-10 (Eq. 4-1)

ASCE/SEI 7-10 (Eq. 4-1)

Where:

L = reduced design live load per ft2

of area supported by the member

Lo = unreduced design live load per ft2

of area supported by the member = 80 psf

KLL = live load element factor =

4 ASCE/SEI

7-10 (Table 4-2)

AT = tributary area  ft2

ft2

psf

psf

Which

satisfies  requirement for members supporting two or more floors.

requirement for members supporting two or more floors.

ASCE/SEI 7-10 (4.7.2)

Roof Level Loads

Dead Loads, D

Weight of the

joist = 82.83 psf.

No

superimposed dead load at the roof

Roof Live

Load, Lr: Calculate the roof live load reduction

;

;

ASCE/SEI

7-10 (Eq 4-2)

ASCE/SEI

7-10 (Eq 4-2)

Where:

psf

psf

,

since 200 ft2 < At = 480 ft2

< 600 ft2

,

since 200 ft2 < At = 480 ft2

< 600 ft2

for

flat roof

for

flat roof

psf

psf

Total Factored Load on 1st

story edge column (@ 1st interior support)

Total Floor Load

kips

kips

Total Roof Load lb

lb kips

kips

Assume 20 in square column with 4 – #

11 vertical bars with design axial strength,  of

of

ACI 318-14 (22.4.2)

ACI 318-14 (22.4.2)

lb

lb

kips

kips

Column Self-weight  kips

kips

Total Reaction @ 1st

interior support  kips

kips

kips.

kips.

Therefore, the preliminary edge

column size of 20 in. x 20 in. is adequate.

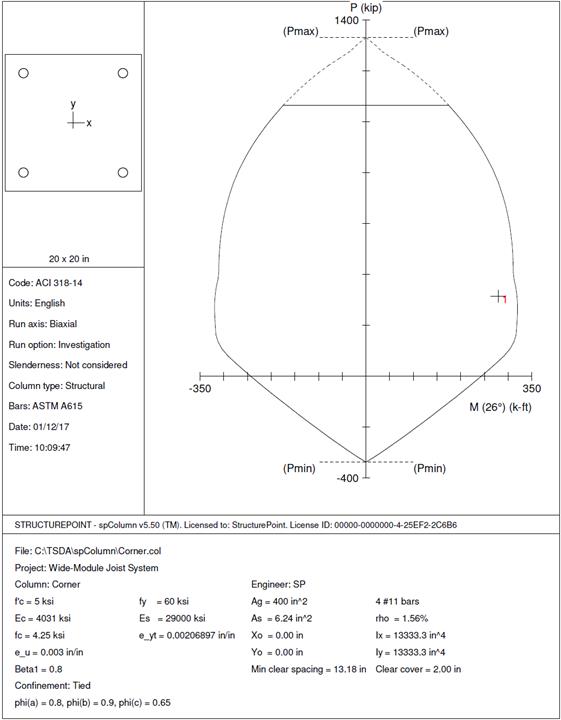

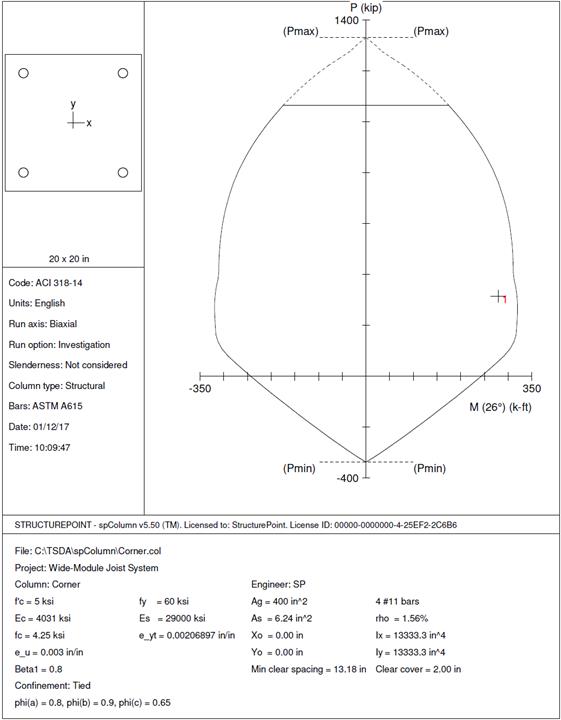

c.

Corner Columns

Select a preliminary size based on

the axial load demand. Therefore, the load take-down for a corner column is

done as follows:

The governing load combination:  ACI

318-14 (Eq. 5.3.1b)

ACI

318-14 (Eq. 5.3.1b)

Typical Floor Level Loads

# of Floors = 4

Dead Loads, D

Self-weight

of wide-module joist system (see Figure 2):

Weight of the

joist = 82.83 psf.

Superimposed dead load = 20 psf

Live Load, L:

Calculate the live load reduction per ASCE/SEI 7-10

ASCE/SEI 7-10 (Eq. 4-1)

ASCE/SEI 7-10 (Eq. 4-1)

Where:

L = reduced design live load per ft2

of area supported by the member

Lo = unreduced design live load per ft2

of area supported by the member = 80 psf

KLL = live load element factor =

4 ASCE/SEI

7-10 (Table 4-2)

AT = tributary area  ft2

ft2

psf

psf

Which

satisfies  requirement for members supporting two or more floors.

requirement for members supporting two or more floors.

ASCE/SEI 7-10 (4.7.2)

Roof Level Loads

Dead Loads, D

Weight of the

joist = 82.83 psf.

No

superimposed dead load at the roof

Roof Live

Load, Lr: Calculate the roof live load reduction

;

;  ASCE/SEI

7-10 (Eq 4-2)

ASCE/SEI

7-10 (Eq 4-2)

Where:

psf

psf

,

since 200 ft2 < At = 240 ft2

< 600 ft2

,

since 200 ft2 < At = 240 ft2

< 600 ft2

for

flat roof

for

flat roof

psf

psf

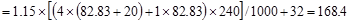

Total Factored Load on 1st

story corner column (@ exterior support)

Total Floor Load

kips

kips

Total Roof Load lb

lb kips

kips

Assume 20 in square column with 4 – #

11 vertical bars with design axial strength,  of

of

ACI 318-14 (22.4.2)

ACI 318-14 (22.4.2)

lb

lb

kips

kips

Column Self-weight  kips

kips

Total Reaction @ exterior support  kips

kips

kips.

kips.

Therefore, the preliminary edge

column size of 20 in. x 20 in. is adequate.

The design of the

following structural members is performed and compared with results of the

engineering software program spBeam:

2.1. One-Way Slab

2.2. One-Way Joist

2.3. Interior Beam

2.4. Exterior Beam

2.5. Interior Column

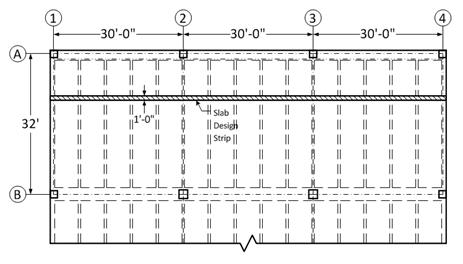

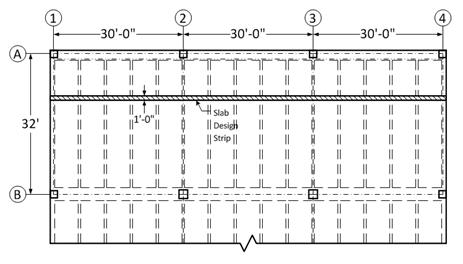

A unit strip of

1 ft is considered for the design of slab spanning between ribs. Note that ACI

318-14 does not allow live load reduction for one-way slabs.

Figure

2.1 – Partial plan view illustrating slab design strip

Slab design

involves the following steps:

2.1.1. Determination of span loads

2.1.2. Determination of design moments and shears

2.1.3. Flexural Design

2.1.4. Shear Design

2.1.5. Deflections

2.1.6. Computer Program Solution

2.1.7. Summary and comparison of design results

2.1.8. Conclusions and observations

The

following gravity load combinations are considered:

ACI 318-14 (Eq. 5.3.1a)

ACI 318-14 (Eq. 5.3.1a)

kips/ft

per ft

kips/ft

per ft

ACI 318-14 (Eq. 5.3.1b)

ACI 318-14 (Eq. 5.3.1b)

kips/ft

per ft

kips/ft

per ft

Span loads are governed by the

second load combination.

The factored moment and shear can

be determined using the simplified method if the requirements are

satisfied: ACI

318-14 (6.5.1)

ü Members are prismatic.

ü Loads are uniformly distributed.

ü L ≤ 3D (0.08 kips/ft per ft ≤

3 x 0.0825 kips/ft per ft)

ü There are at least two spans.

ü The longer of two adjacent spans does

not exceed the shorter by more than 20 percent.

Thus, the approximate coefficients

can be used. The factored moments and shears are determined and summarized in

the following tables. ACI

318-14 (Table 6.5.2 and Table 6.5.3)

|

Table 2.1.2.1

– One-Way Slab Design Moment Values

|

|

Location

|

Design Moment

Value

|

|

End Spans

|

Exterior Support Negative

|

ft-kips/ft ft-kips/ft

|

|

Mid-span

|

ft-kips/ft ft-kips/ft

|

|

Interior Support Negative

|

ft-kips/ft ft-kips/ft

|

|

Interior Spans

|

Mid-span Positive

|

ft-kips/ft ft-kips/ft

|

|

Support Negative

|

ft-kips/ft ft-kips/ft

|

|

Table 2.1.2.2

– One-Way Slab Design Shear Values

|

|

Location

|

Design Shear

Value

|

|

End Span at Face of First Interior

Support

|

kips/ft kips/ft

|

|

At Face of all other Supports

|

kips/ft kips/ft

|

For the one-way slab of a wide-module joist system, a

single layer of longitudinal reinforcement is provided. The first interior

support negative moment governs the design as tabulated in Table 2.1.2.1.

Therefore, it is favorable to place the single layer reinforcement closer to

the top fiber of the concrete slab. The required reinforcement shall be

calculated for the first interior support negative moment first. The required

reinforcement for the end span positive moment shall also be calculated as the

low effective depth due to the reinforcement location may govern the required

reinforcement amount. Finally, the required reinforcement for design shall be

checked against the minimum shrinkage and temperature reinforcement requirement

per ACI 318-14 (24.4.3.2).

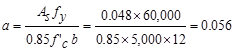

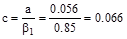

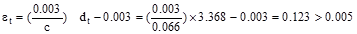

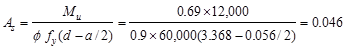

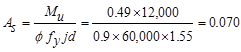

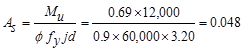

Calculate

the required reinforcement to resist the first interior support negative

moment:

ft-kips/ft

ft-kips/ft

Use welded wire fabric reinforcement, 6 x 6-W5.5 x

W5.5 with 1.5 in. concrete cover. The distance from extreme compression fiber

to the centroid of longitudinal tension reinforcement, d, is calculated

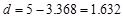

below:

in.

in.

To determine the area of steel,

assumptions have to be made whether the section is tension or compression

controlled, and regarding the distance between the resultant compression and

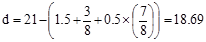

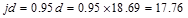

tension forces along the slab section (jd). In this example,

tension-controlled section will be assumed so the reduction factor is

equal to 0.9, and jd will be taken equal to 0.95d. The

assumptions will be verified once the area of steel is finalized.

is

equal to 0.9, and jd will be taken equal to 0.95d. The

assumptions will be verified once the area of steel is finalized.

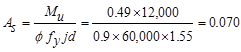

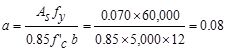

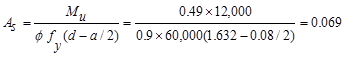

Assume in.

in.

Unit

strip width, b = 12 in.

in.2/ft

in.2/ft

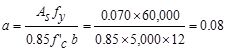

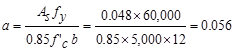

Recalculate

‘a’ for the actual As = 1.31 in.2:  in.

in.

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

in.2/ft

in.2/ft

Calculate

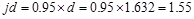

the required reinforcement to resist the positive moment:

ft-kips/ft

ft-kips/ft

The

distance from extreme compression fiber to the centroid of longitudinal tension

reinforcement:

in.

in.

To determine the area of steel,

assumptions have to be made whether the section is tension or compression

controlled, and regarding the distance between the resultant compression and

tension forces along the slab section (jd). In this example,

tension-controlled section will be assumed so the reduction factor is

equal to 0.9, and jd will be taken equal to 0.95d. The

assumptions will be verified once the area of steel is finalized.

is

equal to 0.9, and jd will be taken equal to 0.95d. The

assumptions will be verified once the area of steel is finalized.

Assume in.

in.

Unit

strip width, b = 12 in.

in.2/ft

in.2/ft

Recalculate

‘a’ for the actual As = 0.070 in.2:  in.

in.

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

in.2/ft

in.2/ft

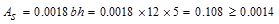

Check

the shrinkage and temperature reinforcement requirement:

in.2

/ ft ACI 318-14 (Table 24.4.3.2)

in.2

/ ft ACI 318-14 (Table 24.4.3.2)

Check

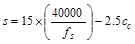

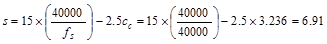

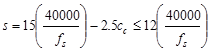

reinforcement spacing for crack control:

The

maximum spacing of the flexural reinforcement closest to the tension face of

the slab shall be:

,

but not greater than

,

but not greater than  ACI

318-14 (Table 24.3.2)

ACI

318-14 (Table 24.3.2)

Where:

Maximum

reinforcement spacing for crack control, in

Maximum

reinforcement spacing for crack control, in

Calculated

stress in reinforcement closest to the tension face at service load, ksi

Calculated

stress in reinforcement closest to the tension face at service load, ksi

The

least distance from surface of reinforcement to the tension face, in

The

least distance from surface of reinforcement to the tension face, in

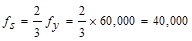

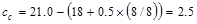

psi

ACI 318-14 (24.3.2.1)

psi

ACI 318-14 (24.3.2.1)

in.

for reinforcement resisting negative moment at supports (i.e. tension at the

top)

in.

for reinforcement resisting negative moment at supports (i.e. tension at the

top)

in.

for reinforcement resisting positive moment at mid-span (i.e. tension at the

bottom)

in.

for reinforcement resisting positive moment at mid-span (i.e. tension at the

bottom)

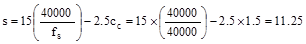

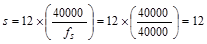

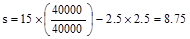

Thus,

At

supports

in

(governs @ support)

in

(governs @ support)

But not greater than  in.

in.

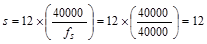

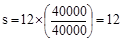

At

mid-span

in

(governs @ mid-span)

in

(governs @ mid-span)

But not greater than  in.

in.

Therefore, for this one-way slab, the shrinkage and

temperature reinforcement requirement per ACI 318-14 (Table

24.4.3.2) governs the required

reinforcement area ( in2/ft)

and crack control requirement per ACI 318-14 (Table 24.3.2)

governs the reinforcement spacing (

in2/ft)

and crack control requirement per ACI 318-14 (Table 24.3.2)

governs the reinforcement spacing ( in.).

in.).

The most feasible reinforcement solution that meets

both requirements mentioned above is to provide welded wire fabric

reinforcement, 6 x 6-W5.5 x W5.5. Note that the welded wire reinforcement

selected provides minimum shrinkage and temperature reinforcement in the slab

direction parallel to the joists as well. Alternately, deformed bars can be

utilized in lieu of welded wire fabric. It should be noted that two conditions

specific to this design contribute to having such a stringent spacing

requirement.

These are listed below:

- The 5 in. slab

has a single layer reinforcement that is placed near the top surface (i.e.

clear cover from the top surface to the reinforcement is 1.5 in. This result in

a high cc value for the calculation of reinforcement spacing for

crack control due to positive moment.

- The stress in

reinforcement closest to the tension face at service load, fs,

is taken as 2/3 fy as permitted by ACI 318-14

without calculation. It is very likely that under the loading considered, the

stress in the steel will be lower than 2/3 fy. The fs

value is expected to be in the range of 1/3 fy to 1/2 fy.

Even if it is assumed to be 1/2 fy , s value will be 12 in.

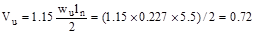

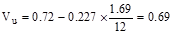

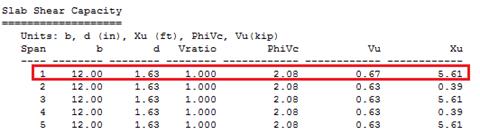

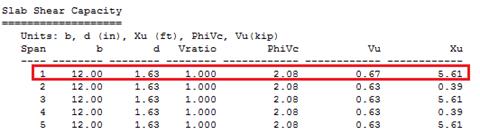

From Table

2.1.2.2 above, the shear value in end span at face of first interior support

governs.

kips/ft

kips/ft

The design shear

at a distance, d, away from the face of support,

kips/ft

kips/ft

Shear strength

provided by concrete

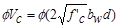

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

lb/ft

lb/ft

kips/ft

kips/ft

kips/ft

kips/ft

kips/ft

.

kips/ft

.

Therefore, the

slab shear capacity is adequate.

Since the preliminary slab thickness met minimum thickness requirement,

the deflection calculations are not required. Unless governed by fire rating

requirements; as in this example; lesser thicknesses and consequently cost savings

can be achieved through deflection computations. Deflection values are

calculated and provided for every model created by spBeam Program and can be

used by the engineer to make additional optimization decisions.

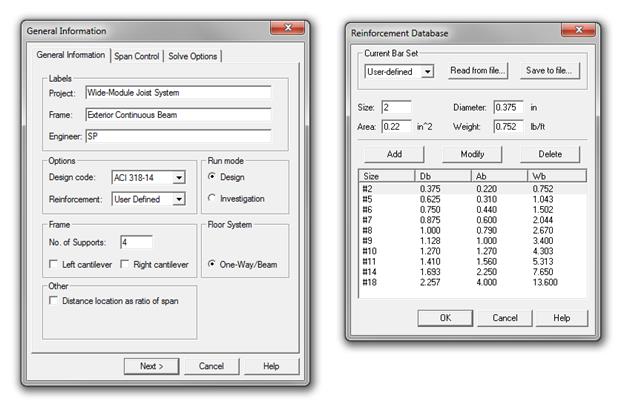

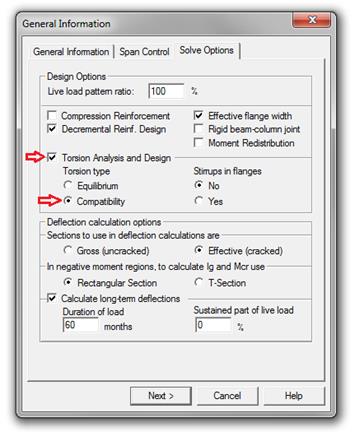

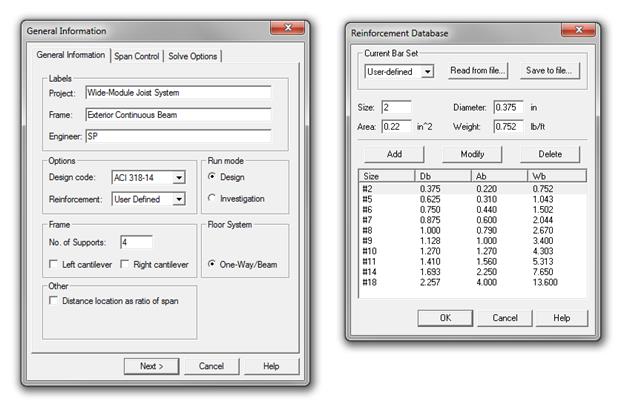

spBeam Program

can be utilized to analysis and design beams and one-way slab systems. The

one-way slab is modeled as 1-ft unit strip supported on ribs. The ribs provide

some rotational stiffness at the supports. In spBeam solution, the rotational

stiffness is assumed as 32,000* kip-in/rad for modeling the joist

supports. Also, for one-way slab run, the rib widths assumed as 6 in. and

modeled through dummy columns of 6 in. x 12 in. with zero height (i.e. column

stiffness is zero, but the 6 in. dimension of the column is utilized to push

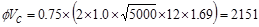

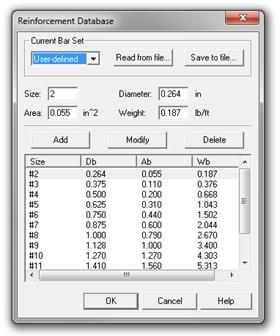

the design moments 3 in. from the support centerline). In this example,

user-defined bar size #2 is defined in spBeam to represent welded wire fabric,

W5.5, with the cross-sectional area of 0.055 in2 (see Fig. 2.1.6.1).

Figure

2.1.6.1 – spBeam Reinforcement Database – User-defined Bar Set

The

program calculates the internal forces (shear force and bending moment), moment

and shear capacities, immediate and long-term deflections, and required

reinforcements. The graphical and text results are provided below for input and

output of the spBeam program. The graphical

and text results are provided here for both input and output of the spBeam model.

* Refer to spBeam manual (Chapter 2 – Special

Considerations for One and Two-Way Joist Systems)

* Refer to spBeam manual (Chapter 4 – Defining Boundary

Conditions, Rotational Stiffness)

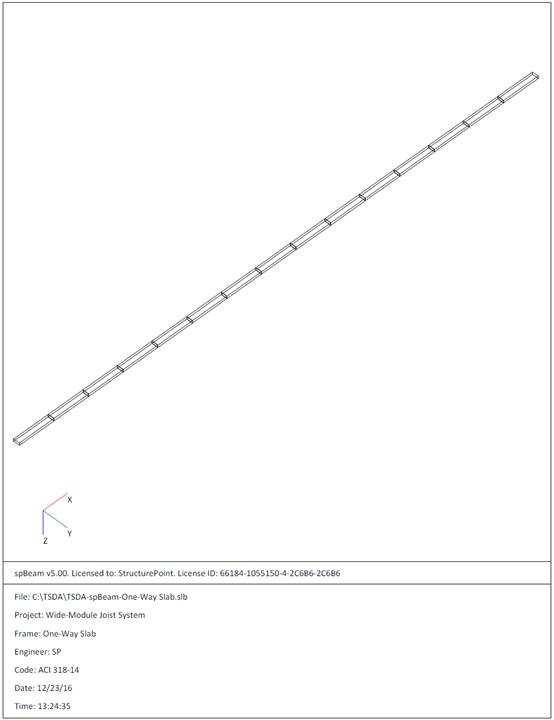

Figure 2.1.6.2 – spBeam Model – Isometric View of 15 Span

– 1ft Wide Unit Strip of One-Way Slab

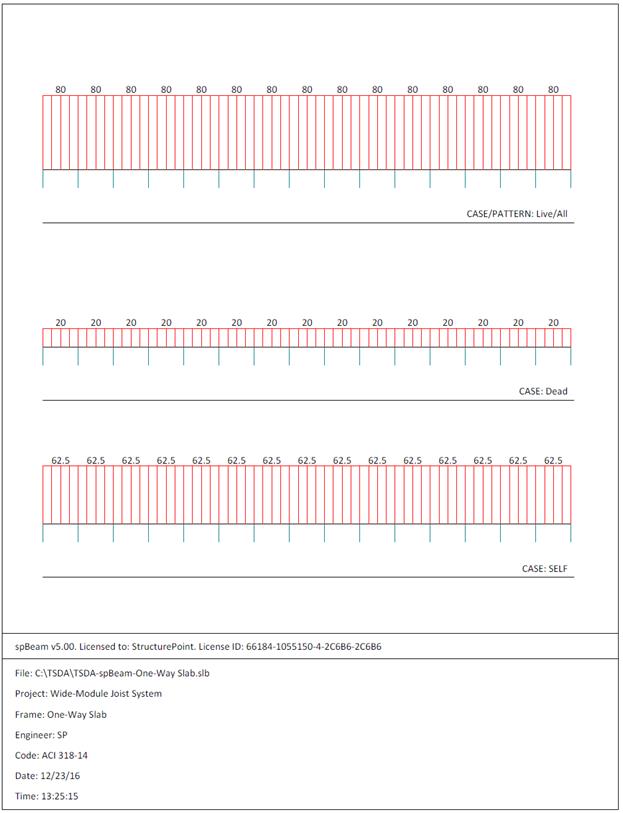

Figure 2.1.6.3 – spBeam Model – Loads (Including Live Load

Patterning) units in lb/ft2

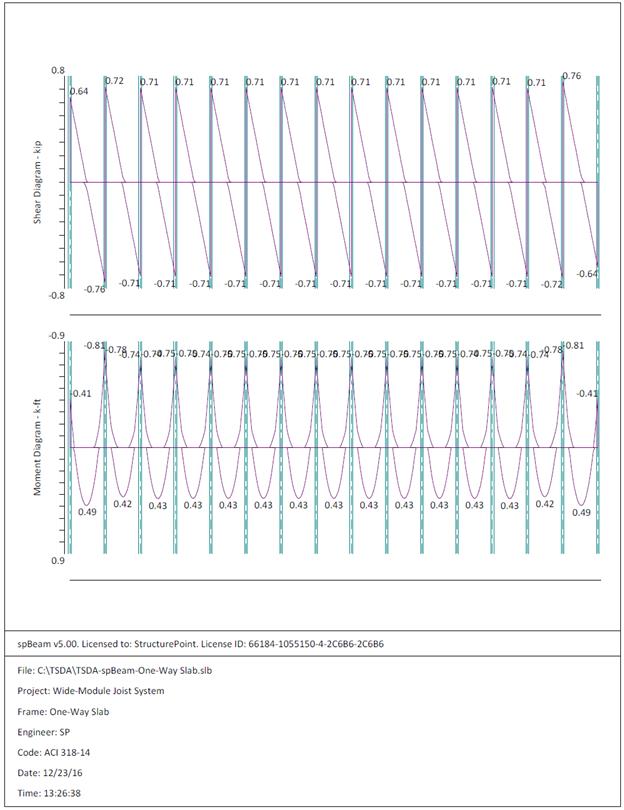

Figure 2.1.6.4 – spBeam Model – Internal Forces (Shear

Force Diagram and Bending Moment Diagram)

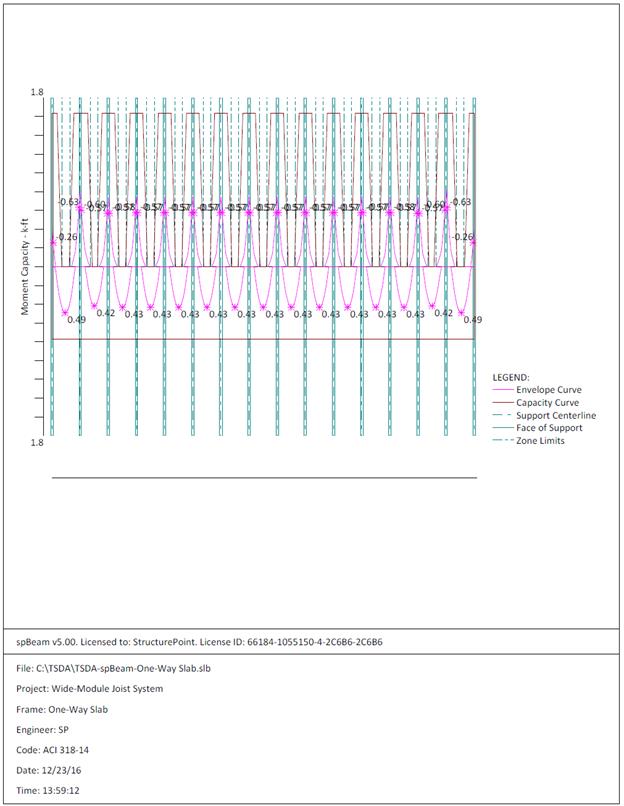

Figure 2.1.6.5 – spBeam Model – Moment Capacity Diagram

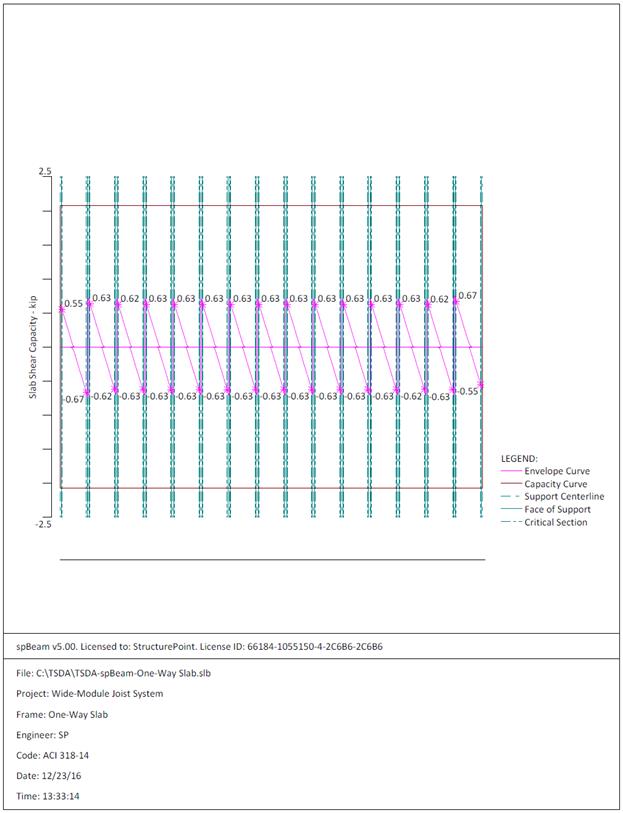

Figure 2.1.6.6 – spBeam Model – Shear Capacity Diagram

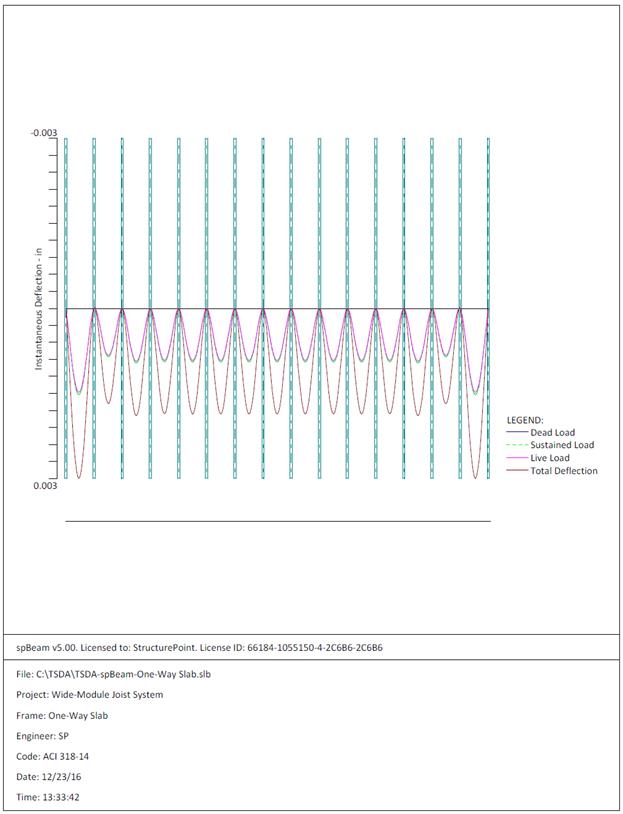

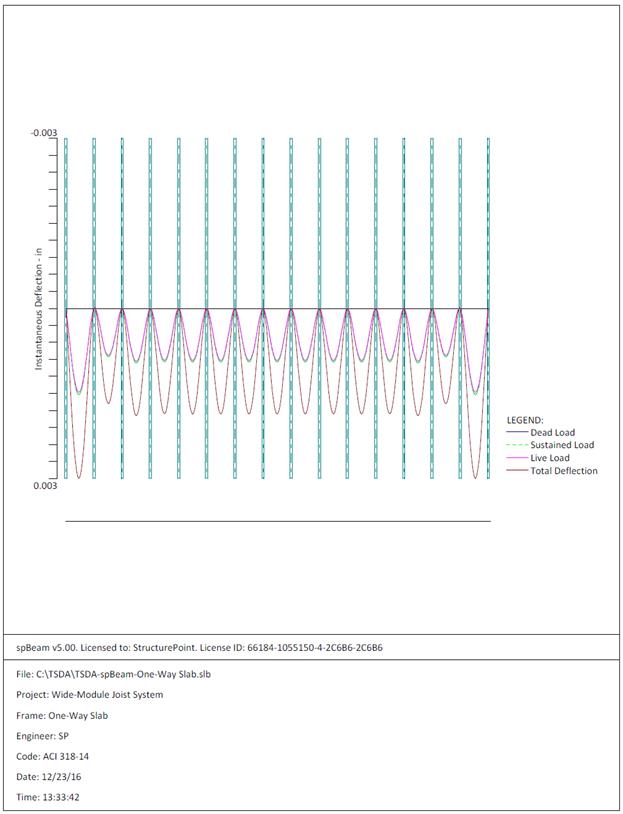

Figure 2.1.6.7 – spBeam Model – Immediate Deflection

Diagram

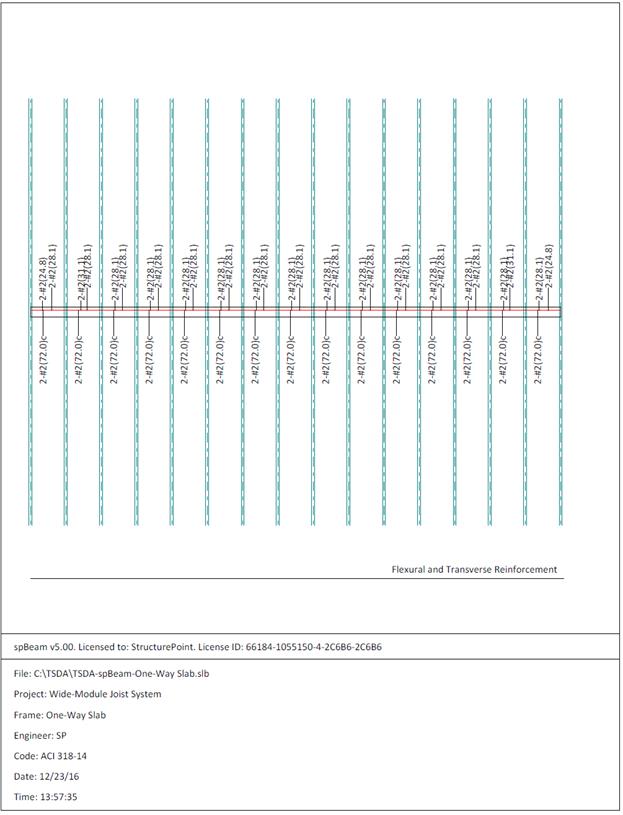

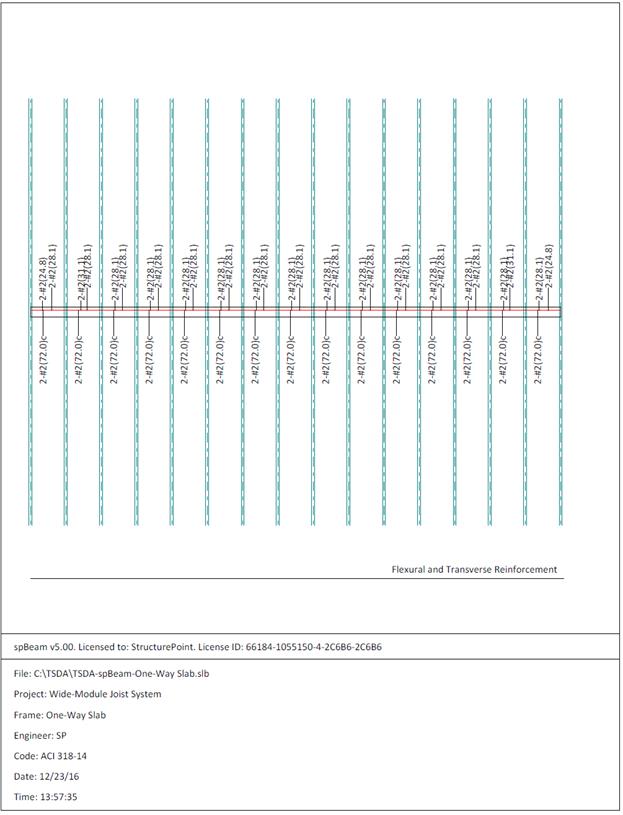

Figure 2.1.6.8 – spBeam Model – Reinforcement Diagram

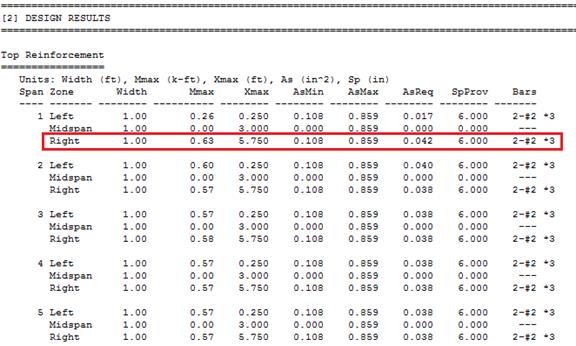

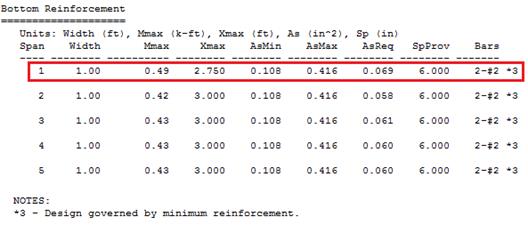

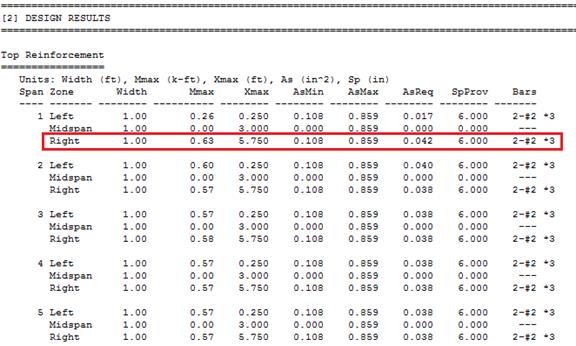

|

Table 2.1.7.1

– Comparison of Hand Solution with spBeam Solution

|

|

Flexural

Design

|

|

Span

Location

|

Design Moment

(ft-kips/ft)

|

Reinforcement

Required

for Flexure

(in2/ft)

|

Minimum

Reinforcement (in2/ft)

(Shrinkage

& Temperature Reinforcement)

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

Interior

Negative

|

0.69

|

0.63

|

0.046

|

0.042

|

0.108

(2-#2)

|

0.108

(2-#2)

|

|

Positive

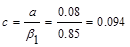

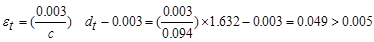

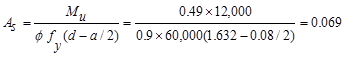

|

0.49

|

0.49

|

0.069

|

0.069

|

0.108

(2-#2)

|

0.108

(2-#2)

|

|

Shear Design

|

|

|

|

Span

Location

|

Vu

(kips/ft)

|

φVn

(kips/ft)

|

|

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

|

|

Interior

Negative

|

0.69

|

0.67

|

2.15

|

2.08

|

|

|

Minimum reinforcement requirement governed flexural design in this

example. spBeam program enables the user to

enter the rotational support springs as boundary conditions for joist supports

and evaluate various analysis and design options beyond the limitations of the

simplified method. The coefficients traditionally used to determine moments do

not address various types of support and geometry.

Typically, in wide-module joist construction, one-way slab is reinforced

with single layer reinforcement placed near the top in the primary direction.

As seen in this example, this may cause crack control criteria to govern the

reinforcement spacing and consequently, it may warrant the use of welded wire

fabric reinforcement instead of deformed bar.

The maximum calculated total immediate (instantaneous) deflection (DL +

LL) = 0.003 in., this value can be compared with maximum permissible calculated

deflection limitation per project criteria in accordance to ACI 318-14.

ACI 318-14 (Table 24.2.2)

In addition to deflection results, parametric studies can be performed in

spBeam to optimize design and detailing

results. Note in the reinforcement diagram (Figure 2.1.6.8) 2-#2 for top

reinforcement in the span left and right zones as well as span bottom

reinforcement. One layer is suitable by inspection (Figure 2.1.6.5) to meet the

required area of steel for top and bottom reinforcement.

The wide-module

joists in this floor are considered as beams per ACI 318-14 (9.8.1.8).

Therefore, the design of the joist shall conform to the requirements of T-beams

per ACI 318-14 (9.2.4).

Figure

2.2 – Partial plan view illustrating one-way joist to be design

Joist design

involves the following steps:

2.2.1. Determination of span loads

2.2.2. Determination of design moments and shears

2.2.3. Flexural Design

2.2.4. Shear Design

2.2.5. Deflections

2.2.6. Computer Program Solution

2.2.7. Summary and comparison of design results

2.2.8. Conclusions and observations

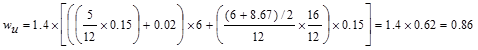

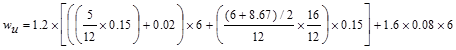

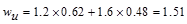

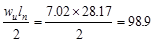

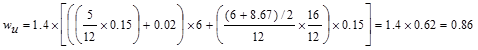

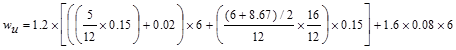

The

following gravity load combinations are considered:

ACI 318-14 (Eq. 5.3.1a)

ACI 318-14 (Eq. 5.3.1a)

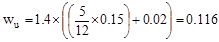

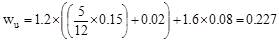

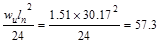

kips/ft

kips/ft

ACI 318-14 (Eq. 5.3.1b)

ACI 318-14 (Eq. 5.3.1b)

kips/ft

kips/ft

Span loads are governed by the

second load combination.

Note that for Floor Live Load

Reduction per ASCE/SEI 7-10:

ASCE/SEI 7-10 (Eq. 4-1)

ASCE/SEI 7-10 (Eq. 4-1)

Where:

Live Load Element Factor,  for

interior beams ASCE/SEI 7-10 (Table

4-2)

for

interior beams ASCE/SEI 7-10 (Table

4-2)

Tributary Area  ft2

ft2

Since ft2

ft2  ft2,

live load reduction is not applicable.

ft2,

live load reduction is not applicable.

The factored moment and shear can

be determined using the simplified method if the requirements are

satisfied:

ACI 318-14 (6.5.1)

ü Members are prismatic.

ü Loads are uniformly distributed.

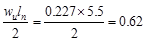

ü L ≤ 3D (0.48 kips/ft ≤ 3

x 0.62 kips/ft)

ü There are at least two spans.

ü The longer of two adjacent spans does

not exceed the shorter by more than 20 percent.

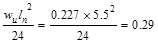

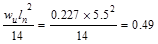

Thus, the approximate coefficients

can be used. The factored moments and shears are determined and summarized in

the following tables. ACI

318-14 (Table 6.5.2 and Table 6.5.3)

|

Table 2.2.2.1

– One-Way Joist Design Moment Values

|

|

Location

|

Design Moment

Value

|

|

End Spans

|

Exterior Support Negative

|

ft-kips ft-kips

|

|

Mid-span

|

ft-kips ft-kips

|

|

Interior Support Negative

|

ft-kips ft-kips

|

|

Interior Spans

|

Mid-span Positive

|

ft-kips ft-kips

|

|

Support Negative

|

ft-kips ft-kips

|

|

Table 2.2.2.2

– One-Way Joist Design Shear Values

|

|

Location

|

Design Shear

Value

|

|

End Span at Face of First Interior

Support

|

kips kips

|

|

At Face of all other Supports

|

kips kips

|

* When support beam is wider than the

column, the clear span, ln, of the joists is measured from the face of the

column. For calculating negative moments, ln, is taken as the

average of the adjacent clear spans.

ACI

318-14 (6.5.2)

For the one-way joist of a wide-module joist system,

the end span moment values govern the design as tabulated in Table 2.2.2.1.

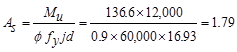

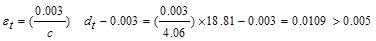

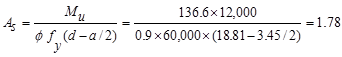

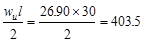

Calculate

the required reinforcement to resist the first interior support negative

moment:

ft-kips

ft-kips

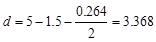

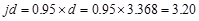

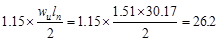

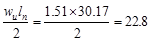

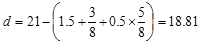

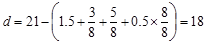

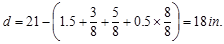

Use #5 reinforcement with 1.5 in. concrete cover. The

distance from extreme compression fiber to the centroid of longitudinal tension

reinforcement, d, is calculated below:

in.

in.

To determine the area of steel,

assumptions have to be made whether the section is tension or compression

controlled, and regarding the distance between the resultant compression and

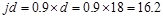

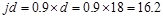

tension forces along the slab section (jd). In this example,

tension-controlled section will be assumed so the reduction factor is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a T-beam (narrow compression zone). The

assumptions will be verified once the area of steel is finalized.

is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a T-beam (narrow compression zone). The

assumptions will be verified once the area of steel is finalized.

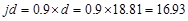

Assume in.

in.

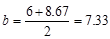

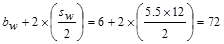

Joist

average width,  in.

in.

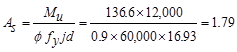

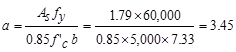

The required reinforcement at initial

trial is calculated as follows:

in.2

in.2

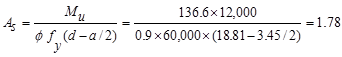

Recalculate

‘a’ for the actual As = 1.79 in.2:  in.

in.

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

in.2

in.2

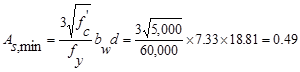

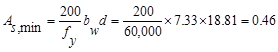

The

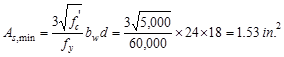

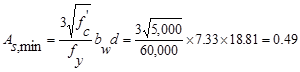

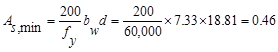

minimum reinforcement shall not be less than

in.2 ACI 318-14 (9.6.1.2(a))

in.2 ACI 318-14 (9.6.1.2(a))

And

not less than

in.2

ACI 318-14 (9.6.1.2(b))

in.2

ACI 318-14 (9.6.1.2(b))

Part of the negative-moment steel

shall be distributed over a width equal to the smaller of the effective flange

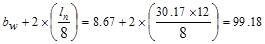

width (72 in) and  in.

ACI 318-14 (24.3.4)

in.

ACI 318-14 (24.3.4)

Where the effective width of the

overhanging flange on each side of the beam web is the smallest of the

following:

ACI 318-14 (6.3.2.1)

in.,

where h is the slab thickness.

in.,

where h is the slab thickness.

in.,

where sw is the clear distance to the adjacent web.

in.,

where sw is the clear distance to the adjacent web.

in

in

Therefore, the effective flange

width is 72 in

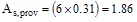

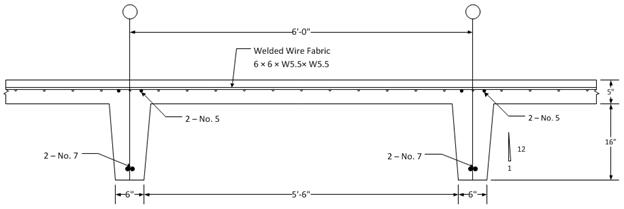

Provide 6-# 5 bars within 38.4 in

width.

in2

in2

in2

o.k.

in2

o.k.

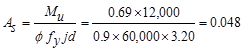

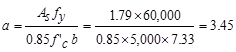

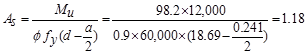

Calculate

the required reinforcement to resist the positive moment:

ft-kips

ft-kips

In

the positive moment regions, the beam acts as a T-shaped beam. The effective

flange width as was calculated earlier is 72 in.

By assuming #3

bars for joist stirrups and the maximum bar size for joist bottom reinforcement

as #7 and following the 1.5 in. concrete cover to reinforcement requirement of

beam stirrups per ACI 318-14 (20.6.1), the distance from

extreme compression fiber to the centroid of longitudinal tension

reinforcement, d, is calculated below:

in

in

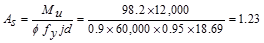

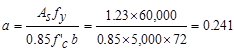

Since we are

designing for the positive moment in a T-Beam (wide compression zone), select a

moment arm, jd approximately equal to 0.95d.Assume that  in.

in.

in2

in2

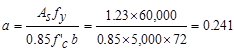

Recalculate

‘a’ for the actual As = 1.23 in.2:  in.

in.

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

in.2

in.2

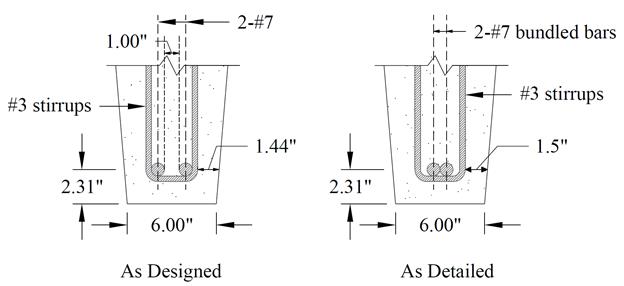

Use 2-#7 bundled

bars with  in2

>

in2

>  in2

o.k.

in2

o.k.

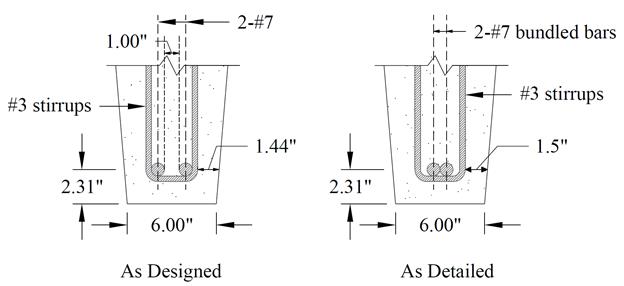

Figure

2.2.3.1 – Cross-sectional view at joist mid-span (Section 2/2.2 in Figure 2.2)

Figure

2.2.3.2 – Cross-sectional view at joist near support face (Section 3/2.2 in

Figure 2.2)

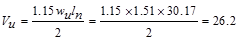

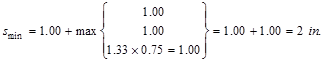

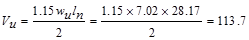

From Table 2.2.2.2 above, the shear

value in end span at face of first interior support governs.

kips

kips

The design shear at a distance, d,

away from the face of support,

kips

/ ft

kips

/ ft

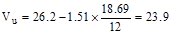

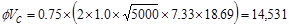

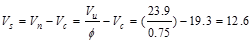

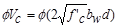

Shear strength provided by concrete

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

lb

lb

kips

kips

Since ,

shear reinforcement is required.

,

shear reinforcement is required.

Try # 3, Grade 60 double-leg

stirrups with a 90° hook.

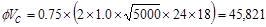

The nominal shear strength required

to be provided by shear reinforcement is

kips

kips

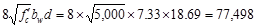

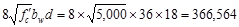

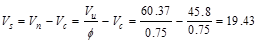

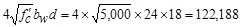

Check whether Vs

is less than

If Vs is greater

than ,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to

,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to .

ACI 318-14 (22.5.1.2)

.

ACI 318-14 (22.5.1.2)

lb

lb

kips

kips

Since  does

not exceed

does

not exceed .

The cross-section is adequate.

.

The cross-section is adequate.

Assume # 3 stirrups with two legs ( in2)

in2)

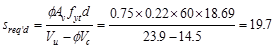

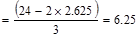

Calculate the required stirrup

spacing as

in.

in.

Check whether the required spacing

based on the shear demand meets the spacing limits for shear reinforcement per ACI 318-14 (9.7.6.2.2).

Check whether Vs

is less than

lb

lb

kips

> Vs = 12.6 kips

kips

> Vs = 12.6 kips

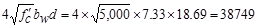

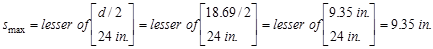

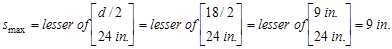

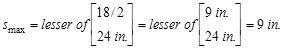

Therefore, maximum stirrup spacing

shall be the smallest of d/2 and 24 in. ACI 318-14 (Table 9.7.6.2.2)

This value governs over the

required stirrup spacing of 19.7 in which was based on the demand.

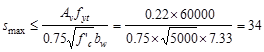

Joist minimum shear reinforcement

requirements must be checked since wide-module joists do not satisfy ACI

318-14 (9.8).

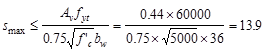

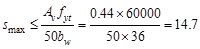

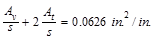

Check the maximum stirrup spacing

based on minimum shear reinforcement

in.

(does not govern) ACI 318-14

(10.6.2.2(a))

in.

(does not govern) ACI 318-14

(10.6.2.2(a))

in.

(does not govern) ACI 318-14 (10.6.2.2(b))

in.

(does not govern) ACI 318-14 (10.6.2.2(b))

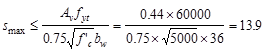

Therefore, smax

value is governed by the spacing limit per ACI 318-14 (9.7.6.2.2),

and is equal to 9.35 in.

Use #3 @ 9 in.

stirrups

ACI 318-14 (22.5.1.1 and 22.5.10.5.3)

ACI 318-14 (22.5.1.1 and 22.5.10.5.3)

kips

kips

kips

>

kips

>  kips

o.k.

kips

o.k.

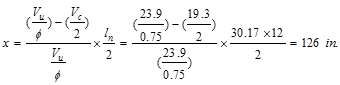

Compute where  is

equal to

is

equal to ,

and the stirrups can be stopped

,

and the stirrups can be stopped

At interior end of the exterior

span, use 16-#3 @ 9 in o.c., Place 1st stirrup 2 in. from the face

of supporting girder.

Since the preliminary joist depth met minimum depth requirement, the

deflection calculations are not required. A lesser depth maybe possible and

consequently cost savings can be achieved through deflection computations.

Deflection values are calculated and provided for every model created by spBeam

Program and can be used by the engineer to make additional optimization

decisions.

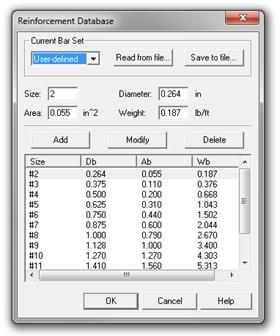

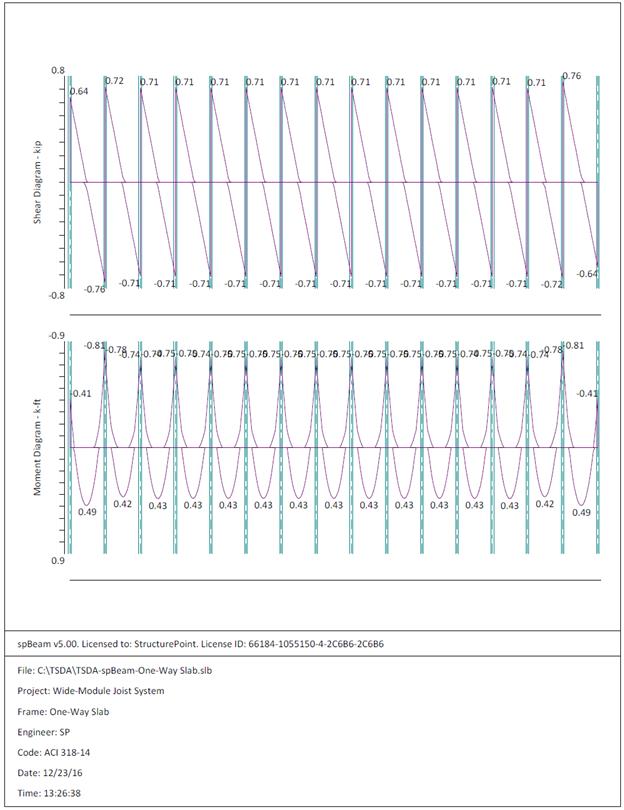

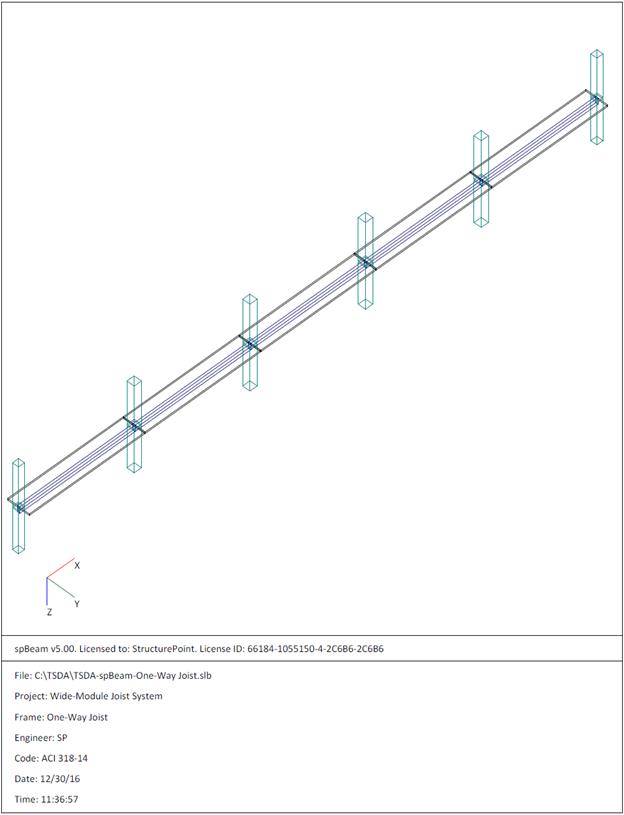

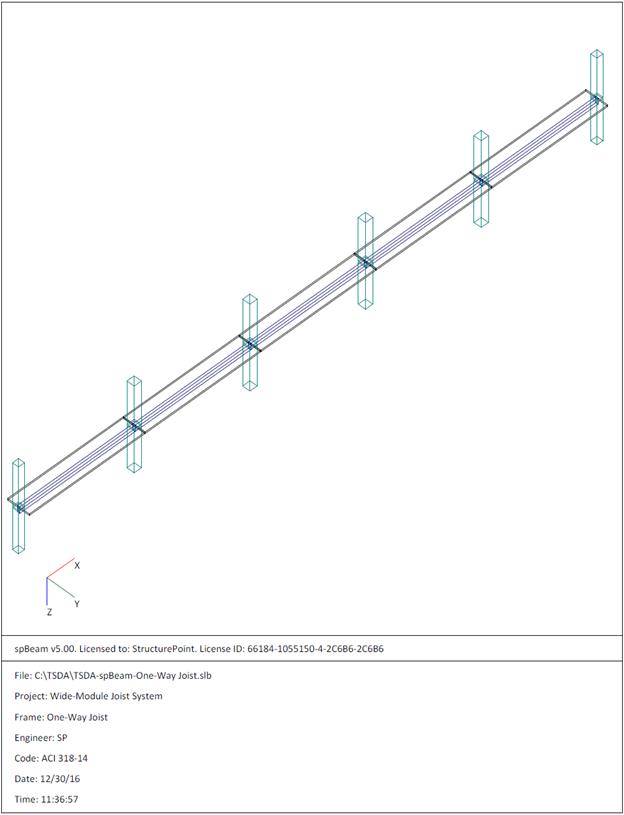

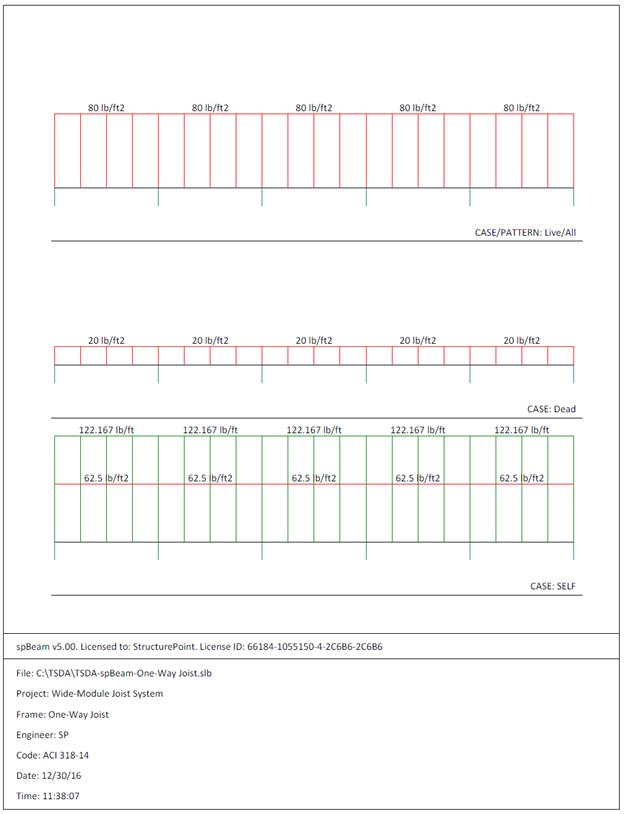

spBeam

Program can be utilized to analysis and design the one-way wide-module joist. A

single wide-module joist is modeled as a five span continuous-beam.

The program

calculates the internal forces (shear force and bending moment), moment and

shear capacities, immediate and long-term deflection results, and required

flexural reinforcement. The graphical and text results are provided here for

both input and output of the spBeam model.

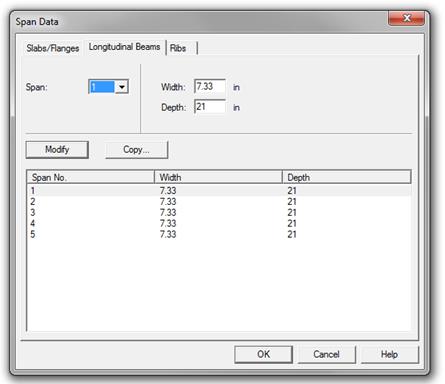

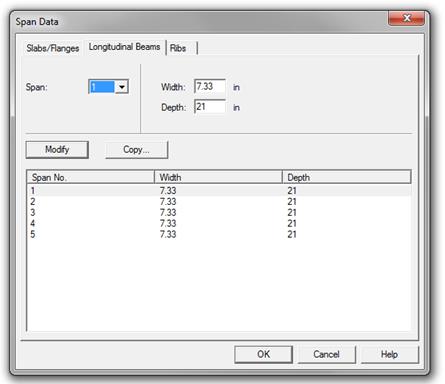

The ribs are

modeled as a rectangular longitudinal beam with an equivalent width of 7.33 in.

and 21 in. depth to reflect the sloped sides of the forming pans.

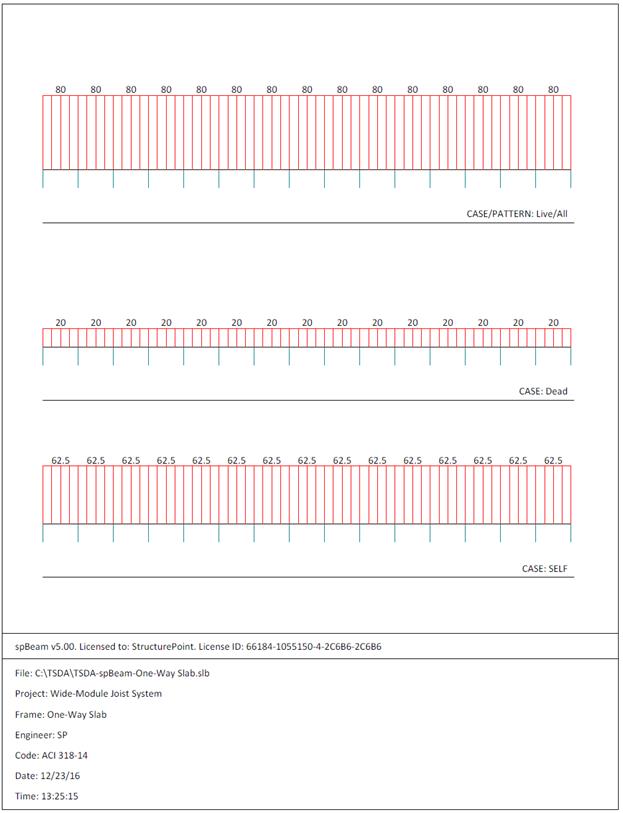

Figure 2.2.6.1 – spBeam Model –One-Way Joist Section

Figure 2.2.6.2 – spBeam Model – Isometric View – One-Way

Joist

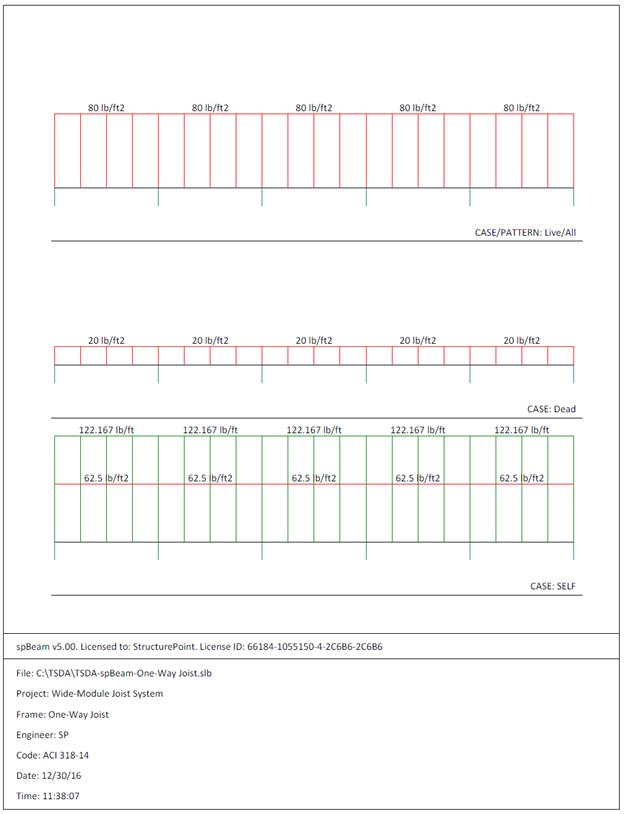

Figure 2.2.6.3 – spBeam Model – Loads (Including Live Load

Patterning)

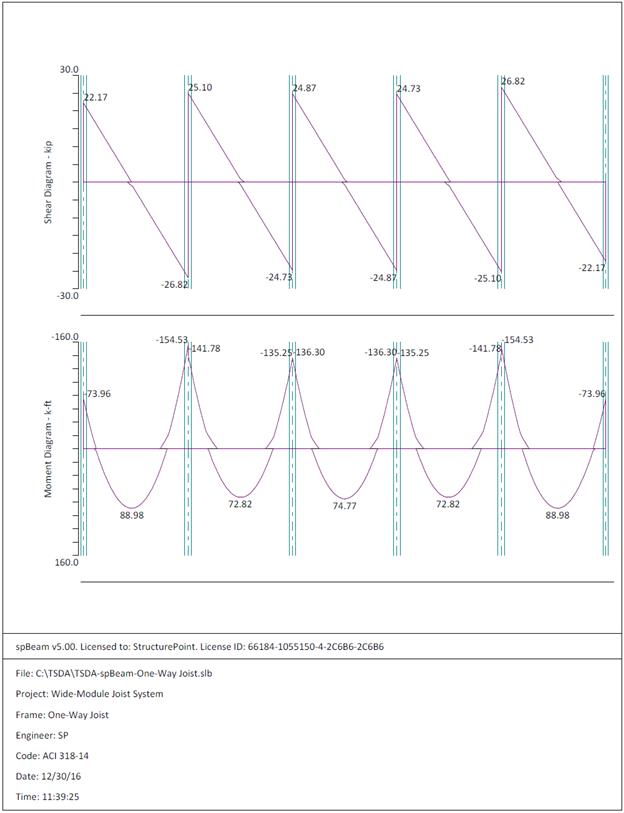

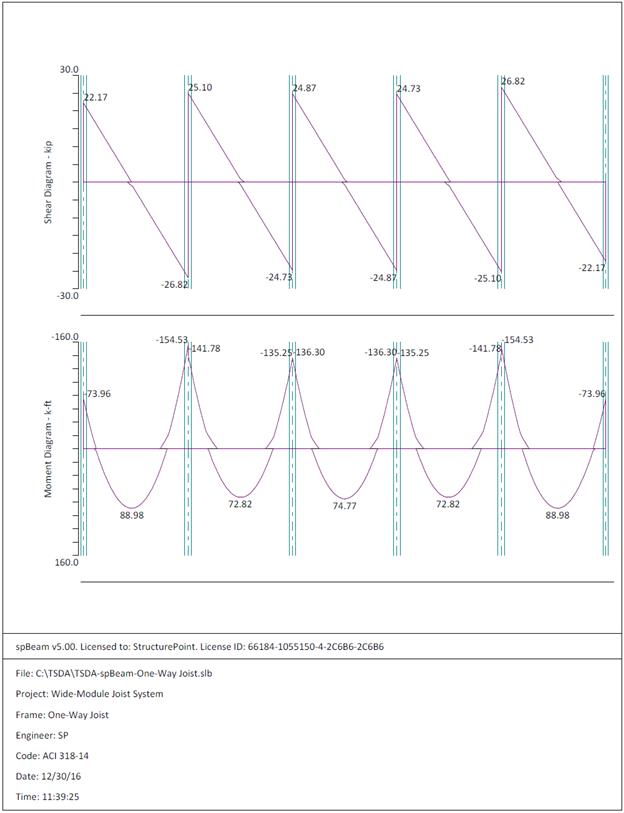

Figure 2.2.6.4 – spBeam Model – Internal Forces (Shear

Force Diagram and Bending Moment Diagram)

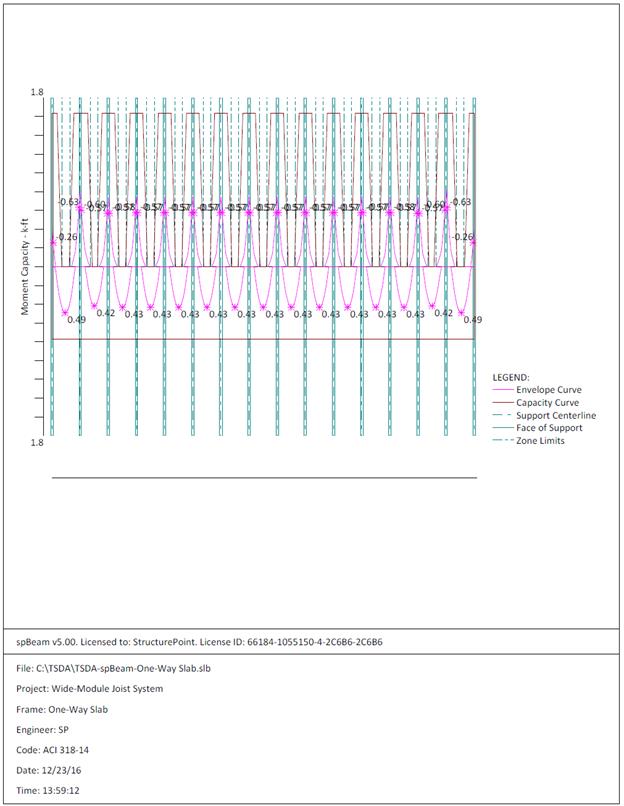

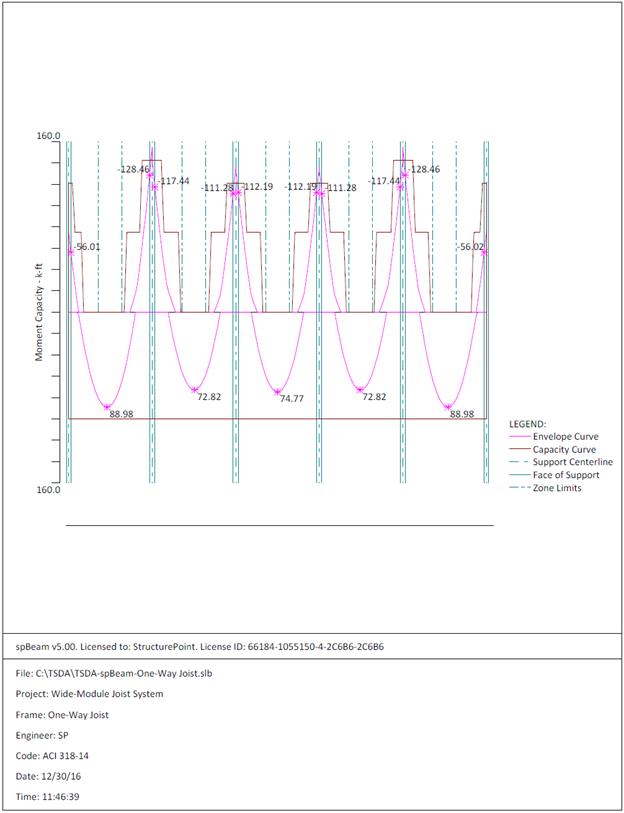

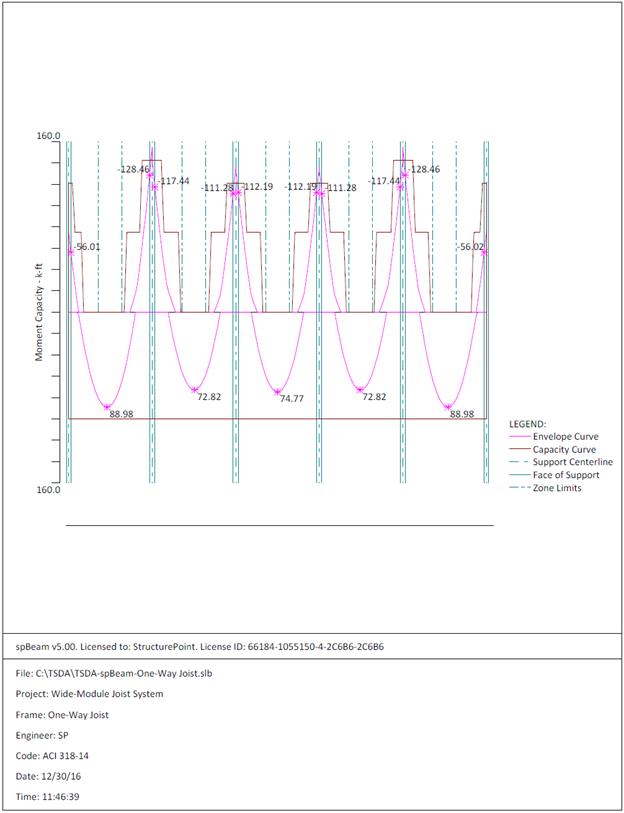

Figure 2.2.6.5 – spBeam Model – Moment Capacity Diagram

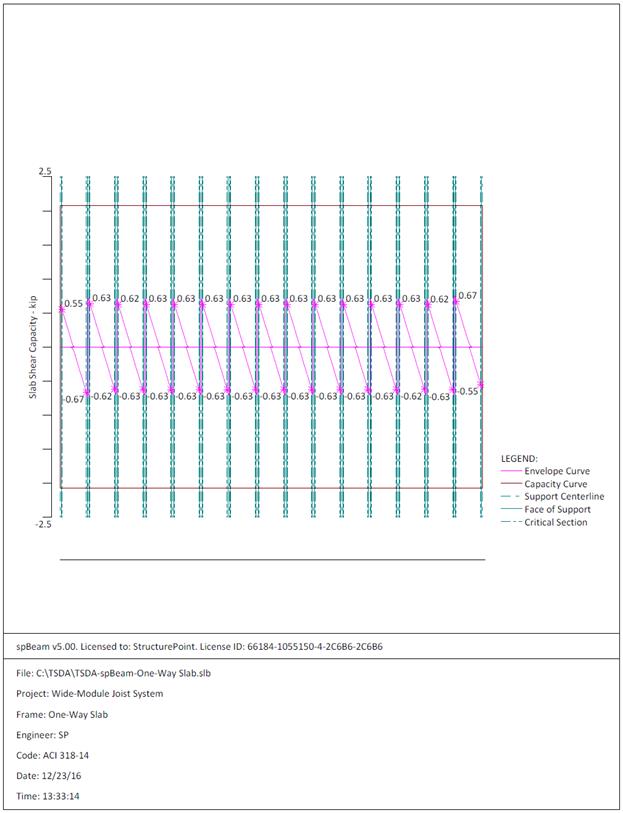

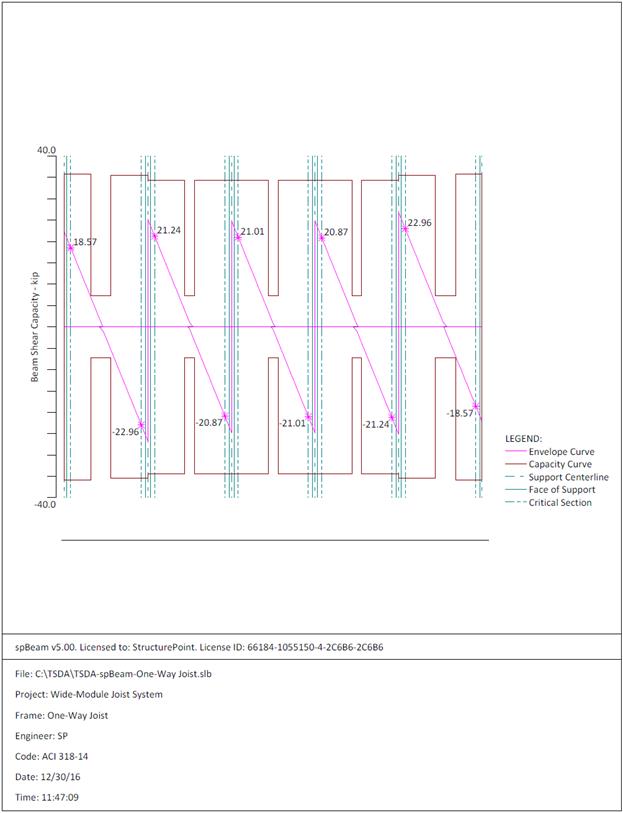

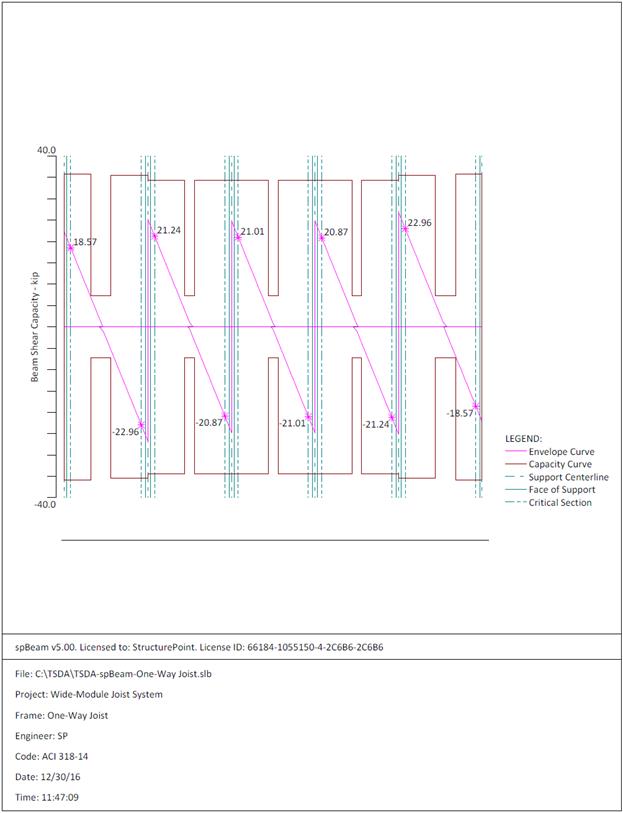

Figure 2.2.6.6 – spBeam Model – Shear Capacity Diagram

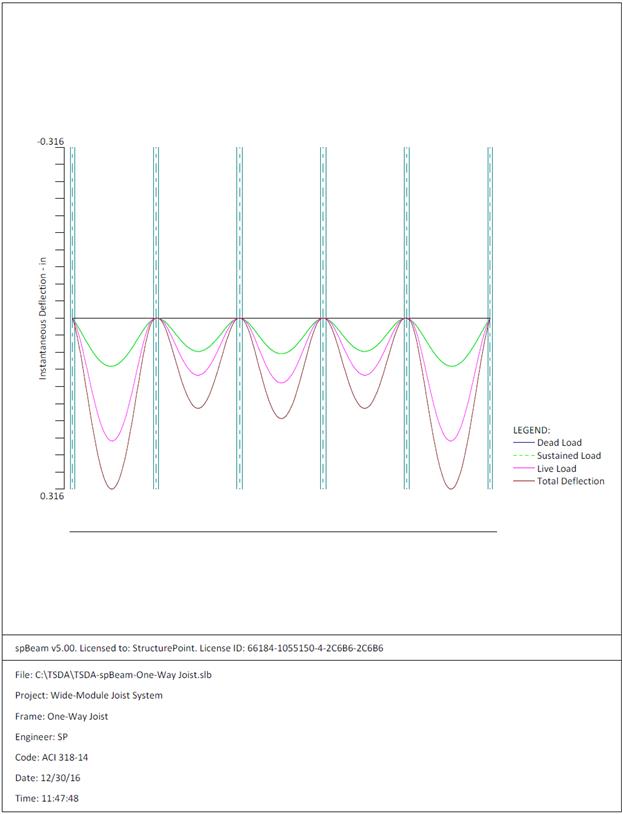

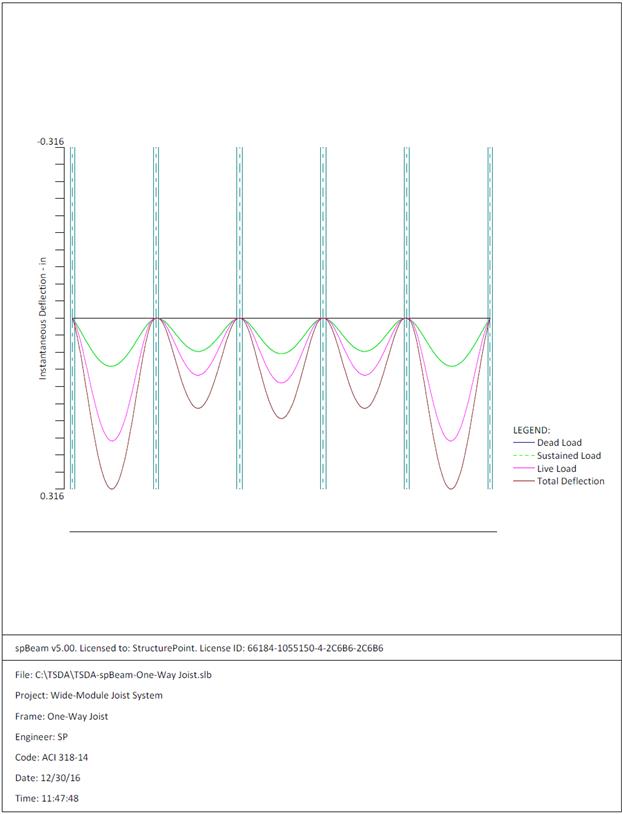

Figure 2.2.6.7 – spBeam Model – Immediate Deflection

Diagram

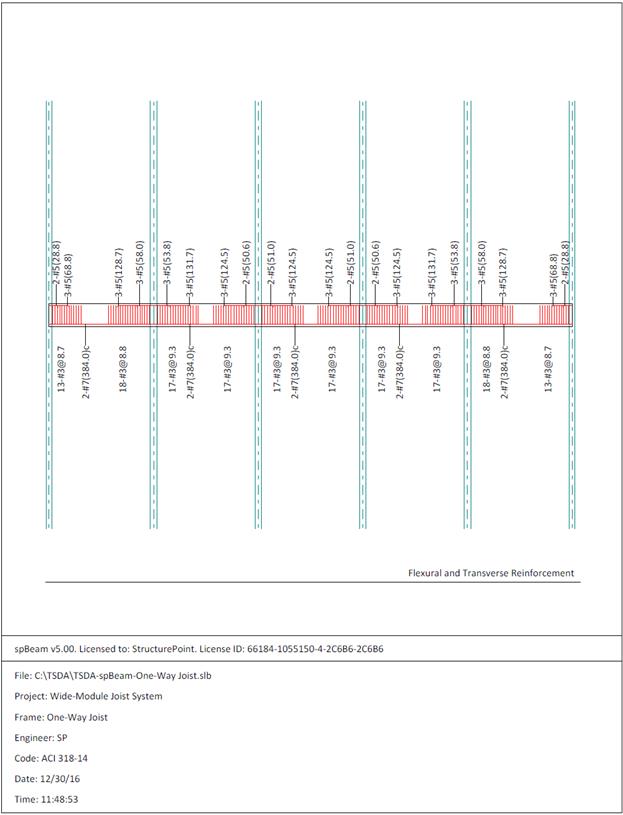

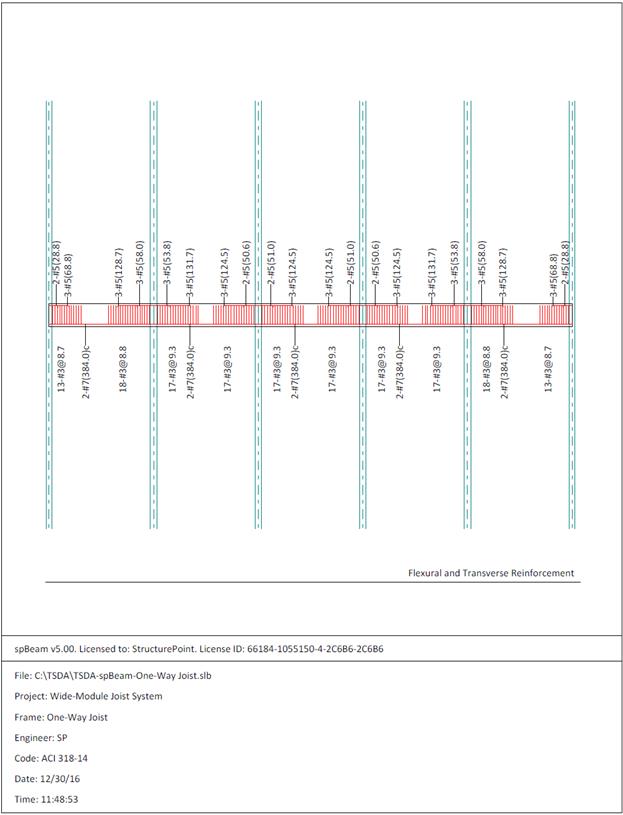

Figure 2.2.6.8 – spBeam Model – Reinforcement Diagram

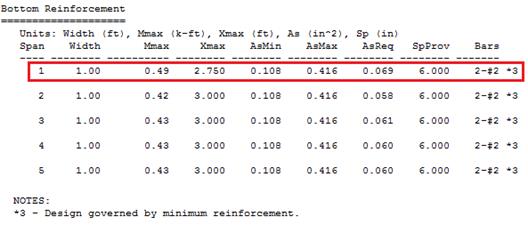

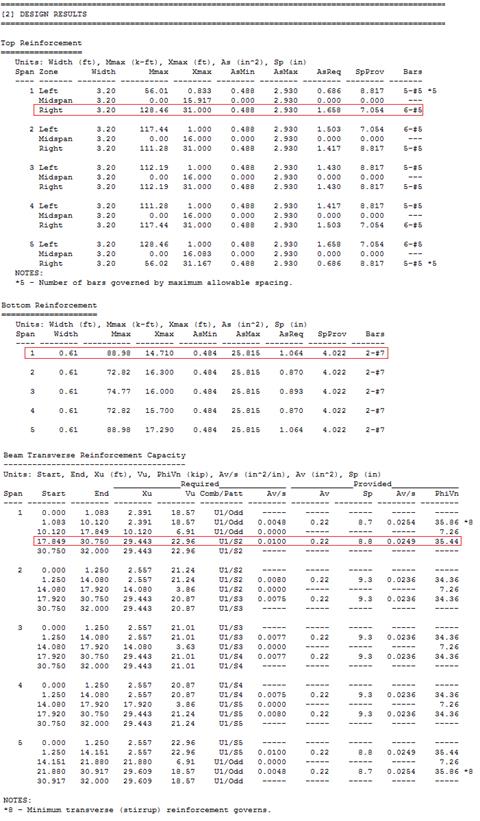

|

Table 2.2.7.1

– Comparison of Hand Solution with spBeam Solution

|

|

Flexural

Design

|

|

Span

Location

|

Design Moment

(ft-kips)

|

Reinforcement

Required

for Flexure

(in2)

|

Reinforcement

Provided

for Flexure

(in2)

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

Interior

Negative

|

136.6

|

128.46

|

1.78

|

1.658

|

6-#5

|

6-#5

|

|

Positive

|

98.2

|

88.98

|

1.18

|

1.064

|

2-#7

|

2-#7

|

|

Shear Design

|

|

|

|

Span

Location

|

Vu

(kips)

|

φVn

(kips)

|

|

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

|

|

Interior

Negative

|

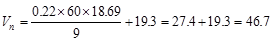

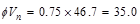

23.9

|

22.96

|

35

|

35.44

|

|

|

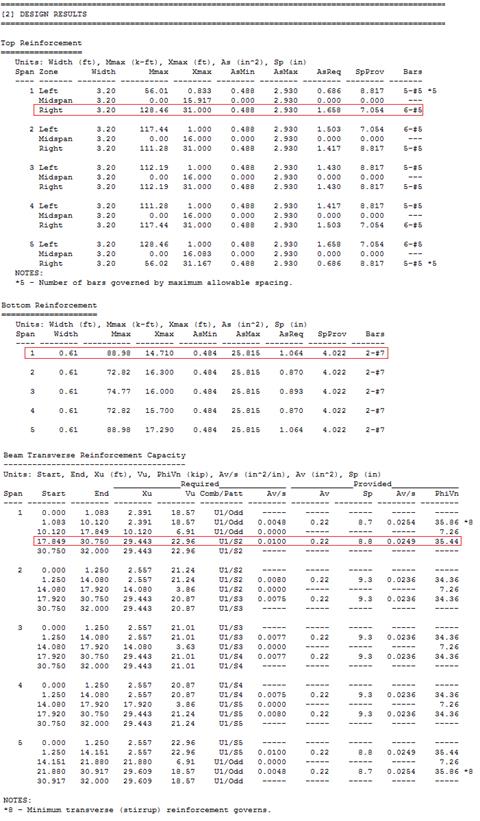

In this design example, the one-way joist system is modeled as a

continuous T-beam representing single one-way joist. There is a good agreement

between the hand solution and computer solution. Note that the coefficients

traditionally used to determine moments do not address various types of support

and geometry.

The maximum calculated total immediate (instantaneous) deflection (DL +

LL) = 0.316 in., this value can be compared with maximum permissible calculated

deflection limitation per project criteria in accordance to ACI 318-14.

ACI 318-14 (Table 24.2.2)

In addition to deflection results,

parametric studies can be performed in spBeam

to optimize design and detailing results. With a minimum spacing of 1 in.

between the 2-#7, two stirrups, and 1.5 in. cover on each side, a total width

of 6.5 in. is required. The rib width at the

bar level is 6.385 in. which is slightly less than required. For detailing

purposes, one of the following options can be used:

1.

Bottom bars can be bundled. This practice is often found in joist construction.

2.

Stirrups can be rotated by a small angle to preserve the minimum spacing.

3. Bottom bars can be raised sufficiently

to achieve the required width taking into the account the reduction into the

moment capacity.

4.

Other detailing options provided by the builder/formwork supply.

Figure 2.2.8 – Joist Cross-Section

In wide-module joist construction, the supporting beam, sometimes

referred to as girder, depth is typically set to match the overall joist depth.

Therefore, the beam depth is set to 21 in. This depth need to satisfy the minimum

depth requirement of ACI 318-14 (Table

9.3.1.1) so that the deflection computations can be waived.

Using the minimum depth for

non-prestressed beams in Table 9.3.1.1.

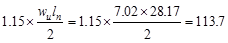

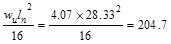

End Span:  in

(governs) < 21 in. ACI 318-14 (Table

9.3.1.1)

in

(governs) < 21 in. ACI 318-14 (Table

9.3.1.1)

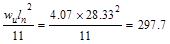

Interior Span:  in

ACI 318-14 (Table 9.3.1.1)

in

ACI 318-14 (Table 9.3.1.1)

Therefore, the preliminary beam depth satisfies the

minimum depth requirement.

Figure

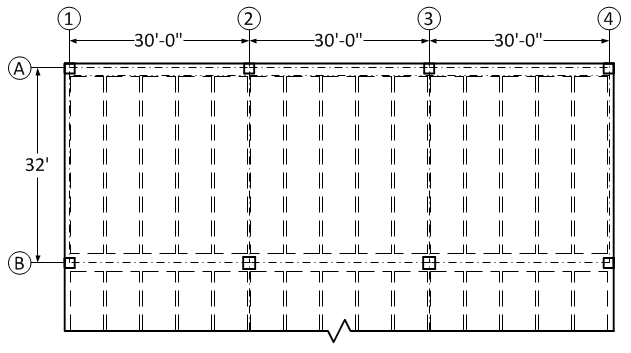

2.3 – Partial plan view showing interior beam along grid B

Beam (girder)

design involves the following steps:

2.3.1. Determination of span loads

2.3.2. Determination of design moments and shears

2.3.3. Flexural Design

2.3.4. Shear Design

2.3.5. Deflections

2.3.6. Computer Program Solution

2.3.7. Summary and comparison of design results

2.3.8. Conclusions and observations

Dead

Load:

Try 36 in width

for the beam (slightly larger than the column width that helps facilitate the

forming, and reduces the beam longitudinal vs. column vertical bar

interference)

Joist & Slab

Weight  kips/ft

kips/ft

Beam Weight  kips/ft

kips/ft

Superimposed

Dead Load, SDL  kips/ft

kips/ft

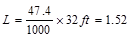

Live

Load:

Check

for live load reduction per ASCE/SEI

7-10

ASCE/SEI 7-10 (Eq. 4-1)

ASCE/SEI 7-10 (Eq. 4-1)

Where:

reduced

design live load per ft2 of area supported by the member

reduced

design live load per ft2 of area supported by the member

unreduced

design live load per ft2 of area supported by the member = 80 psf

unreduced

design live load per ft2 of area supported by the member = 80 psf

live

load element factor = 2 for interior beams ASCE/SEI

7-10 (Table 4-2)

live

load element factor = 2 for interior beams ASCE/SEI

7-10 (Table 4-2)

tributary

area

tributary

area  ft2

ft2

psf

psf

Which

satisfies  requirement for members supporting one floor.

requirement for members supporting one floor.

ASCE/SEI 7-10 (4.7.2)

kips/ft

kips/ft

Load

Combination:

The

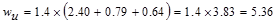

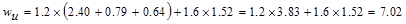

following gravity load combinations are considered:

ACI 318-14 (Eq. 5.3.1a)

ACI 318-14 (Eq. 5.3.1a)

kips/ft

kips/ft

ACI

318-14 (Eq. 5.3.1b)

ACI

318-14 (Eq. 5.3.1b)

kips/ft

kips/ft

The span loads are governed by the

second load combination.

The factored moment and shear can

be determined using the simplified method if the requirements are

satisfied:

ACI 318-14 (6.5.1)

ü Members are prismatic.

ü Loads are uniformly distributed.

ü L ≤ 3D (1.52 kips/ft ≤

3 x 3.83 kips/ft)

ü There are at least two spans.

ü The longer of two adjacent spans does

not exceed the shorter by more than 20 percent.

Thus, the

approximate coefficients can be used. The factored moment and shear are

determined and summarized in the following tables. ACI

318-14 (Table 6.5.2 and Table 6.5.3)

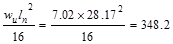

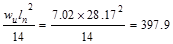

|

Table 2.3.2.1

– Interior Beam Design Moment Values

|

|

Location

|

Design Moment

Value

|

|

End Spans

|

Exterior Support Negative

|

ft-kips ft-kips

|

|

Mid-span

|

ft-kips ft-kips

|

|

Interior Support Negative

|

ft-kips ft-kips

|

|

Interior Spans

|

Mid-span Positive

|

ft-kips ft-kips

|

|

Support Negative

|

ft-kips ft-kips

|

|

Table 2.3.2.2

– Interior Beam Design Shear Values

|

|

Location

|

Design Shear

Value

|

|

End Span at Face of First Interior

Support

|

kips kips

|

|

At Face of all other Supports

|

kips kips

|

For this interior beam, the end span moment values

govern the design as tabulated in Table 2.3.2.1.

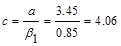

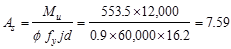

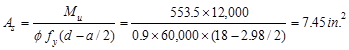

Calculate

the required reinforcement to resist the first interior support negative

moment:

ft-kips

ft-kips

Use #8 bars with 1.5 in. concrete cover per ACI

318-14 (Table 20.6.1.3.1). To avoid interference with joist

negative moment reinforcement, the clear cover to the girder top reinforcement

is required to be increased by lowering the girder top reinforcement. The distance from extreme compression fiber to the

centroid of longitudinal tension reinforcement, d, is calculated below:

in.

in.

To determine the area of steel,

assumptions have to be made whether the section is tension or compression

controlled, and regarding the distance between the resultant compression and

tension forces along the slab section (jd). In this example, tension-controlled

section will be assumed so the reduction factor is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a rectangular beam (narrow compression

zone). The assumptions will be verified once the area of steel is finalized.

is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a rectangular beam (narrow compression

zone). The assumptions will be verified once the area of steel is finalized.

Assume in.

in.

Interior

beam width,  in.

in.

The required reinforcement at initial

trial is calculated as follows:

in.2

in.2

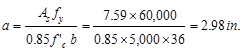

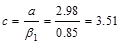

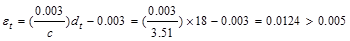

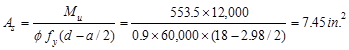

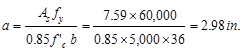

Recalculate

‘a’ for the actual As = 7.59 in.2:

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

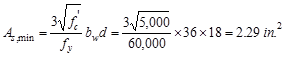

The

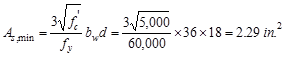

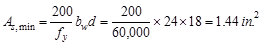

minimum reinforcement shall not be less than

ACI 318-14

(9.6.1.2(a))

ACI 318-14

(9.6.1.2(a))

And

not less than

ACI 318-14 (9.6.1.2(b))

ACI 318-14 (9.6.1.2(b))

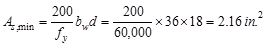

Provide 10 - # 8 bars:

in2

in2

in2

o.k.

in2

o.k.

Maximum spacing allowed:

Check the requirement for

distribution of flexural reinforcement to control flexural cracking:

ACI 318-14 (Table 24.3.2)

ACI 318-14 (Table 24.3.2)

in.

in.

Use  ksi

ACI

318-14 (24.3.2.1)

ksi

ACI

318-14 (24.3.2.1)

in.

(governs)

in.

(governs)

in.

in.

Spacing provided for 10-# 8 bars

in.

in.

in.

o.k.

in.

o.k.

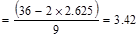

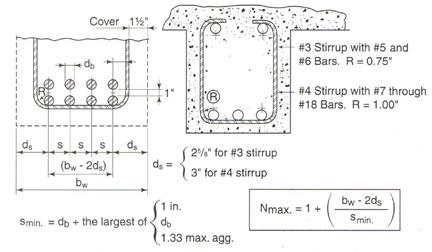

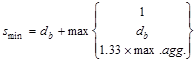

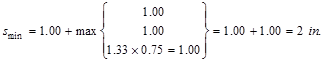

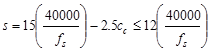

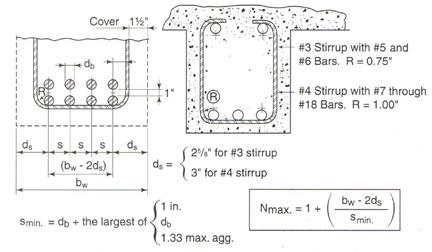

Where ds = 2.625

in. for #3 stirrup as shown in the following Figure. CRSI

2002 (Figure 12-9)

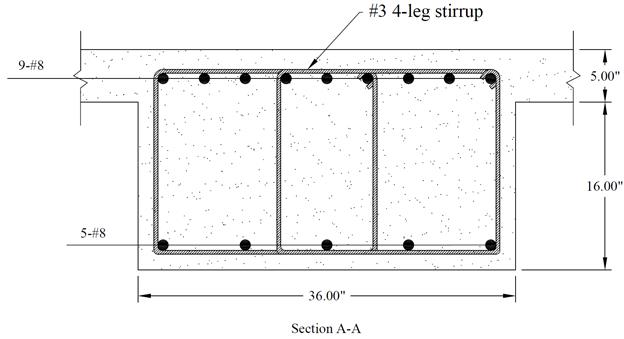

Figure

2.3.3 – Maximum number of bars in beams

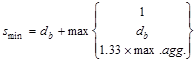

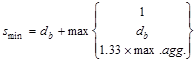

Check the spacing, s provided, is

greater than the minimum center to center spacing, smin where

CRSI 2002 (Figure 12-9)

CRSI 2002 (Figure 12-9)

Where maximum aggregate size is ¾”

Since the spacing provided is

greater than 2 in. Therefore, 10-#8 bars are o.k.

All the values

on Table 2.3.3.1 are calculated based on the procedure outlined above.

|

Table 2.3.3.1

– Reinforcing Design Summary

|

|

|

End Span

|

Interior Span

|

|

|

Exterior

Negative

|

Positive

|

Interior

Negative

|

Positive

|

Negative

|

|

Design Moment, Mu

(ft-kips)

|

348.2

|

397.9

|

553.5

|

344

|

500.3

|

|

Effective depth,

d (in.)

|

18.0*

|

18.625**

|

18*

|

18.625**

|

18*

|

|

As

req’d (in.2)

|

4.53

|

5.03

|

7.45

|

4.31

|

6.68

|

|

As

min (in.2)

|

2.29

|

2.37

|

2.29

|

2.37

|

2.29

|

|

Reinforcement

|

6-#8

|

7-#8

|

10-#8

|

6-#8

|

9-#8

|

|

* The beam top bars are to be placed below the joist top

bars.

|

|

** The beam bottom bars are to be placed at the bottom-most

layer. The joist bottom bars, then, shall be spliced at

joist-beam intersection.

|

From Table 2.3.2.2 above, the shear

value in end span at face of first interior support governs.

kips

kips

The design shear at a distance, d,

away from the face of support,

kips

kips

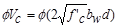

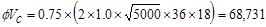

Shear strength provided by concrete

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

lb

lb

kips

kips

Since ,

shear reinforcement is required.

,

shear reinforcement is required.

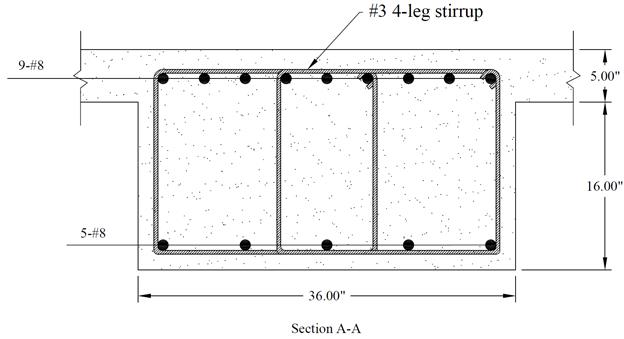

Try # 3, Grade 60 four-leg stirrups

(Av = 0.44 in.2) with a 90° hook.

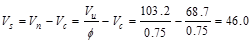

The nominal shear strength required

to be provided by shear reinforcement is

kips

kips

Check whether Vs

is less than

If Vs is greater

than ,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to

,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to .

ACI 318-14 (22.5.1.2)

.

ACI 318-14 (22.5.1.2)

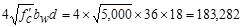

lb

lb

kips

kips

Since  does

not exceed

does

not exceed .

The cross-section is adequate.

.

The cross-section is adequate.

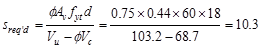

Calculate the required stirrup

spacing as

in.

ACI 318-14 (22.5.10.5.3)

in.

ACI 318-14 (22.5.10.5.3)

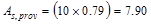

Check whether the required spacing

based on the shear demand meets the spacing limits for shear reinforcement per ACI 318-14 (9.7.6.2.2).

Check whether Vs

is less than

lb

lb

kips

> Vs = 46 kips

kips

> Vs = 46 kips

Therefore, maximum stirrup spacing

shall be the smallest of d/2 and 24 in. ACI 318-14 (Table 9.7.6.2.2)

This value

governs over the required stirrup spacing of 19.7 in which was based on the

demand. Note that since the stirrup spacing is governed by smax, the

size of the stirrup can be kept as # 3. Selecting # 4 stirrup size will produce

capacity more than what is required and therefore, be uneconomical.

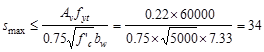

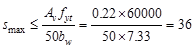

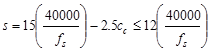

Check the maximum stirrup spacing

based on minimum shear reinforcement

in.

(does not govern) ACI 318-14

(10.6.2.2(a))

in.

(does not govern) ACI 318-14

(10.6.2.2(a))

in.

(does not govern) ACI 318-14 (10.6.2.2(b))

in.

(does not govern) ACI 318-14 (10.6.2.2(b))

Therefore, smax

value is governed by the spacing limit per ACI 318-14 (9.7.6.2.2),

and is equal to 9 in.

Use # 3 @ 8 in.

stirrups

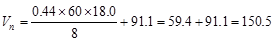

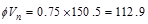

ACI 318-14 (22.5.1.1 and 22.5.10.5.3)

ACI 318-14 (22.5.1.1 and 22.5.10.5.3)

kips

kips

kips

>

kips

>  kips

o.k.

kips

o.k.

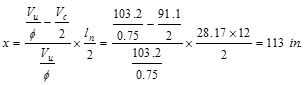

Compute where  is

equal to

is

equal to ,

and the stirrups can be stopped

,

and the stirrups can be stopped

At interior end of the exterior

span, use 16-# 3 @ 8 in o.c., Place 1st stirrup 2 in. from the face

of the column.

Since the preliminary beam depth met minimum depth requirement, the

deflection calculations are not required. A lesser depth maybe possible and

consequently cost savings can be achieved through deflection computations.

Deflection values are calculated and provided for every model created by spBeam

Program and can be used by the engineer to make additional optimization

decisions.

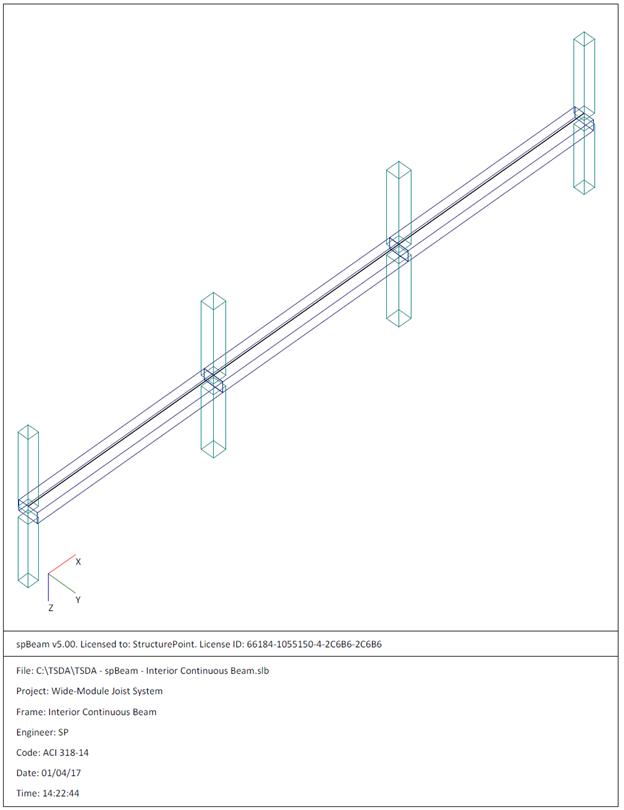

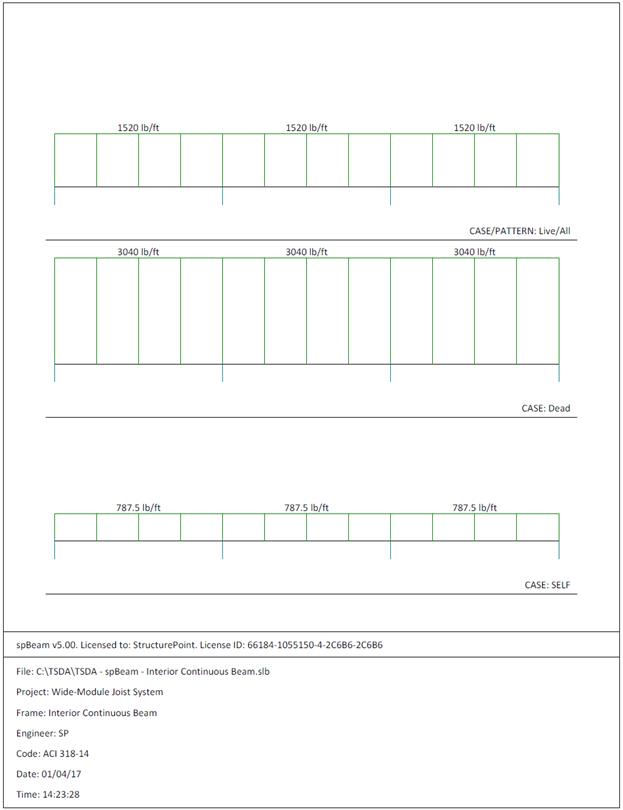

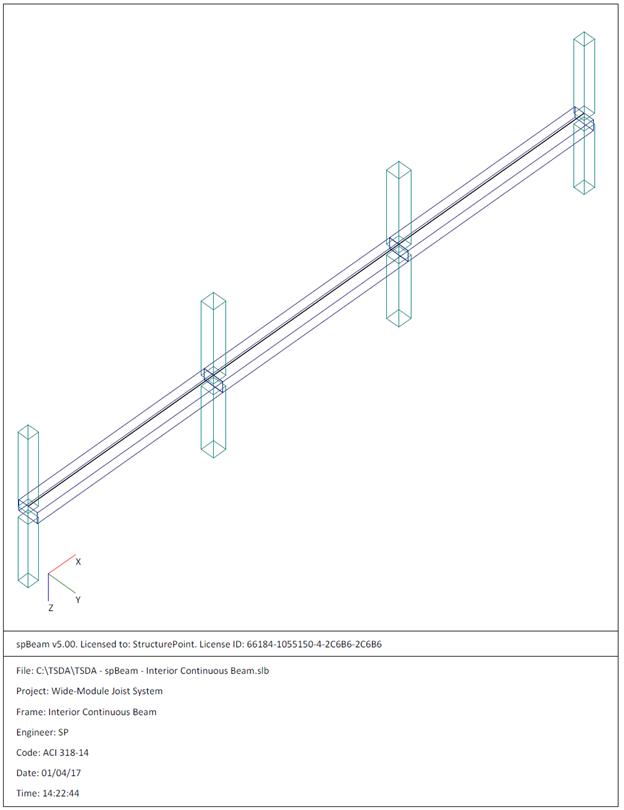

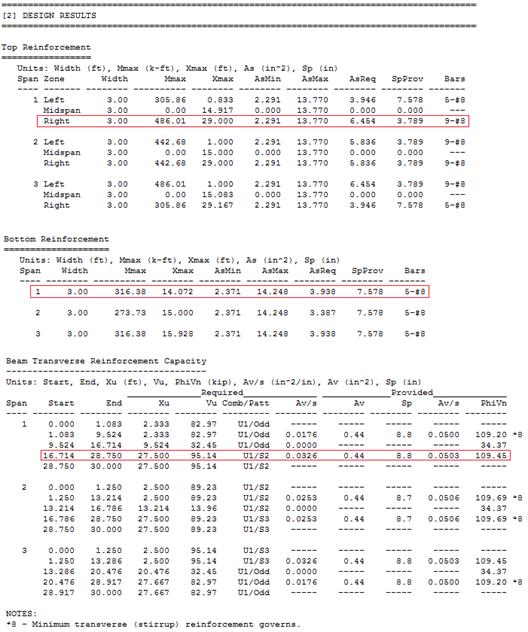

spBeam

Program can be utilized to analyze and design the interior continuous beam

along grid B. The beam is modeled as a three span continuous rectangular beam.

The program

calculates the internal forces (shear force and bending moment), moment and

shear capacities, immediate and long-term deflection results, and required

flexural reinforcement. The graphical and text results are provided here for

both input and output of the spBeam model.

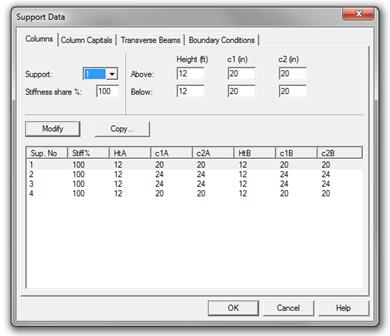

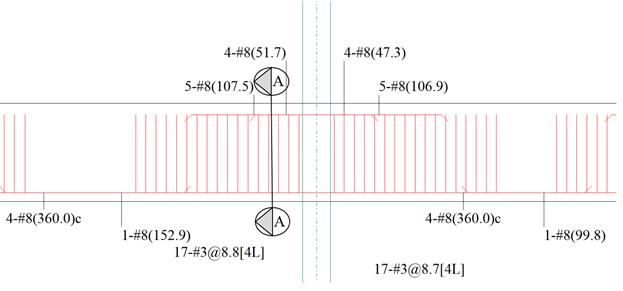

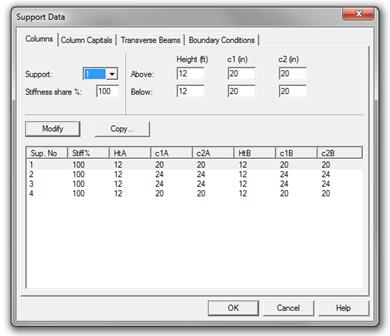

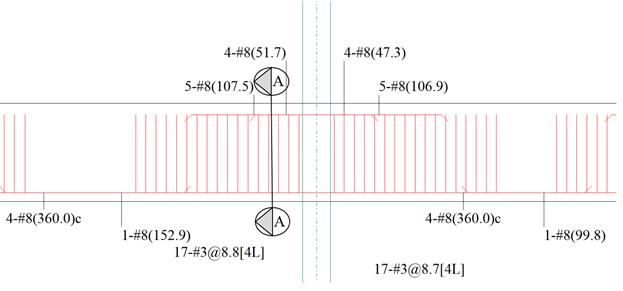

The beam is

modeled as a 36 in. by 21 in. deep rectangular longitudinal beam with column

supports. The supports can be modeled as pinned, fixed, or using actual

geometric properties of the beam-column joint. A value of 100 is used in this

model for column stiffness share, indicating the actual column stiffness. When

the percentage lies between zero and 100%, the joint stiffness contribution by

the column is multiplied by that percentage. The default value is 100%.

Figure 2.3.6.1 – spBeam Model – Support Data

Figure 2.3.6.2 – spBeam Model – Isometric View – Interior

Continuous Beam along Grid B

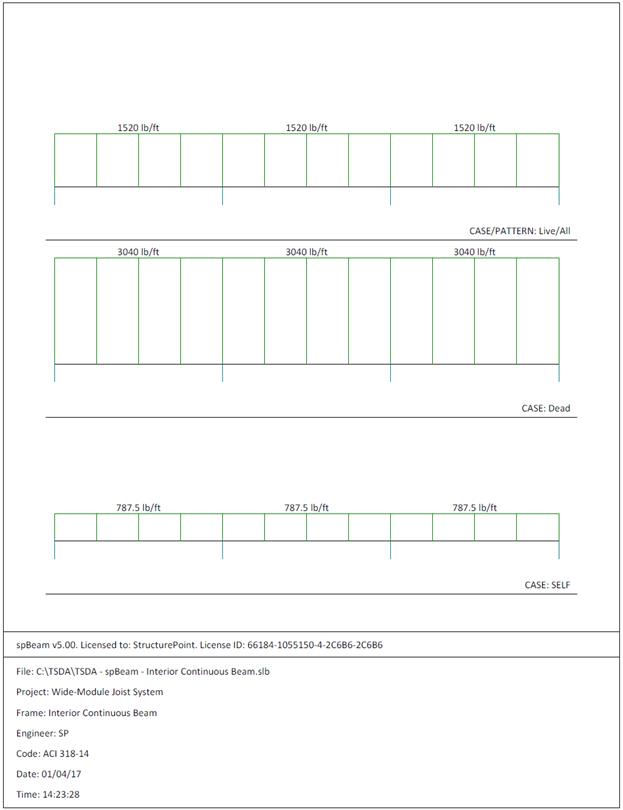

Figure 2.3.6.3 – spBeam Model – Loads (Including Live Load

Patterning)

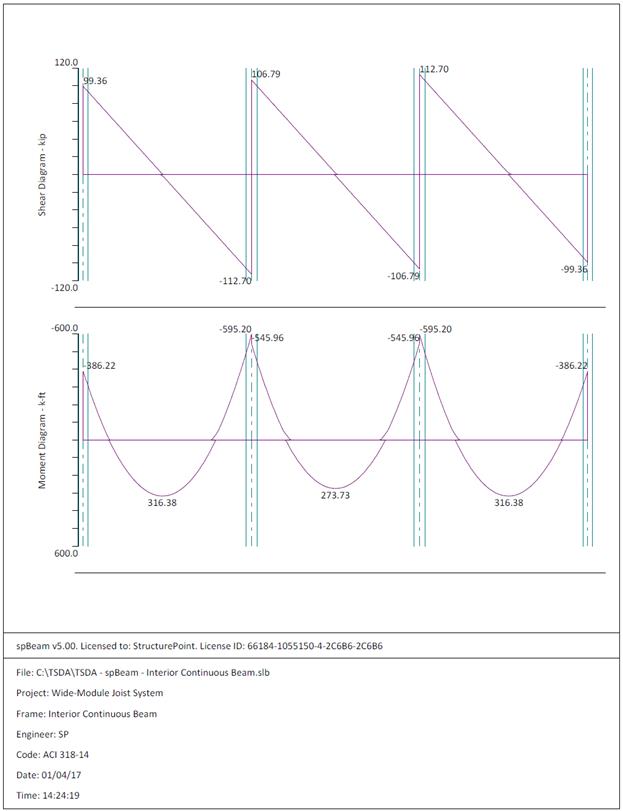

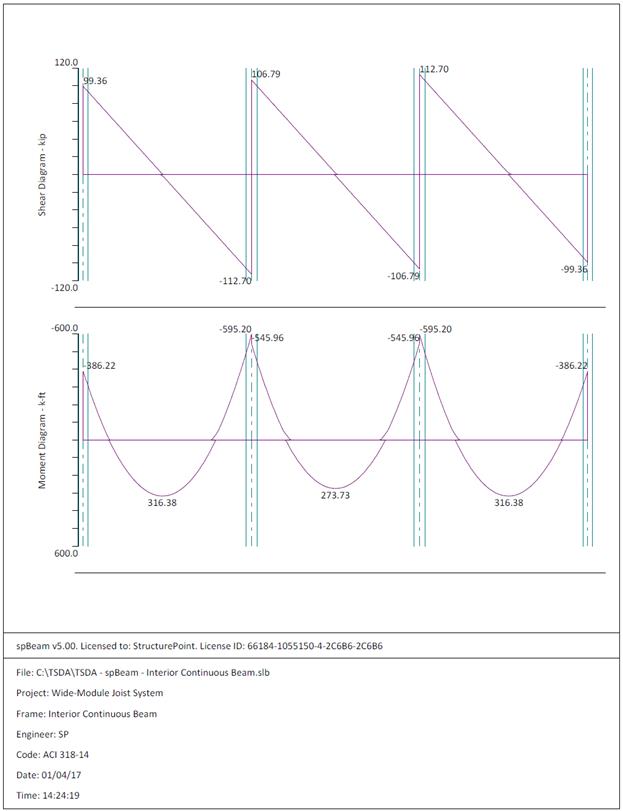

Figure 2.3.6.4 – spBeam Model – Internal Forces (Shear

Force Diagram and Bending Moment Diagram)

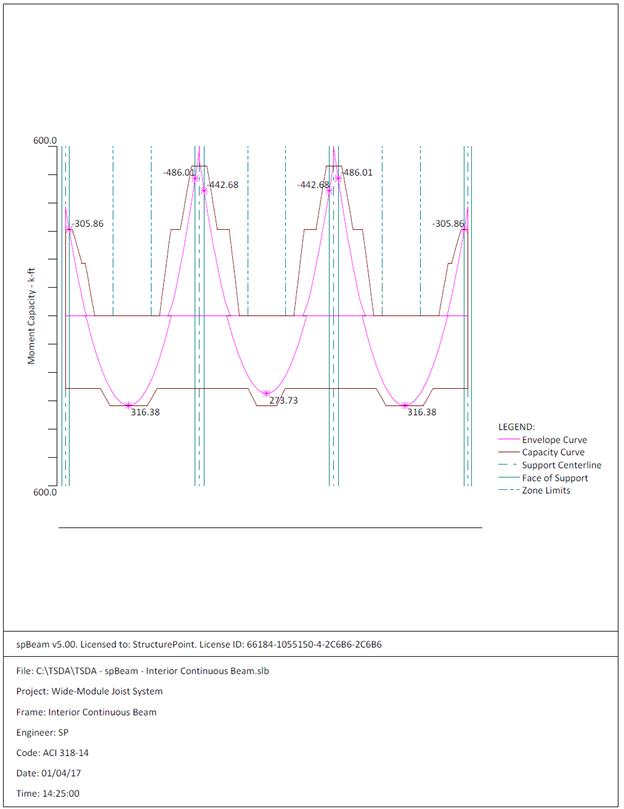

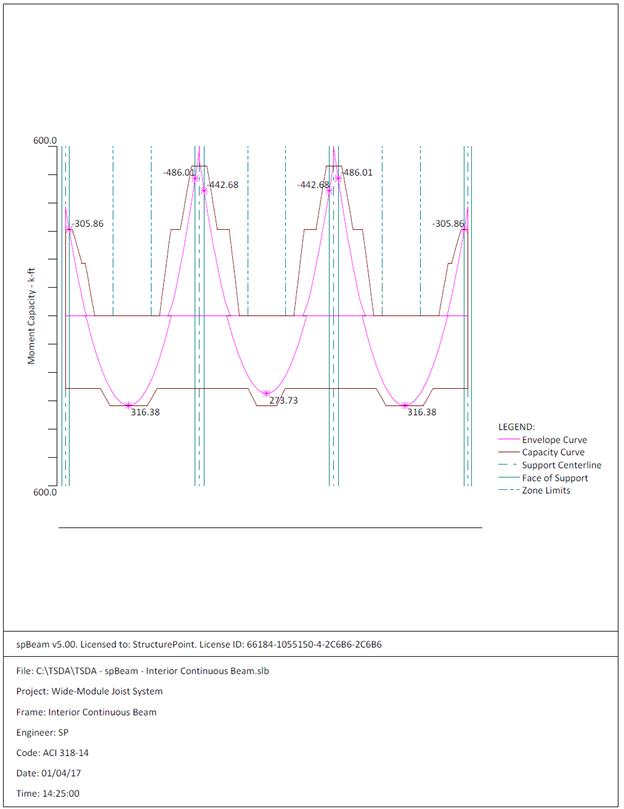

Figure 2.3.6.5 – spBeam Model – Moment Capacity Diagram

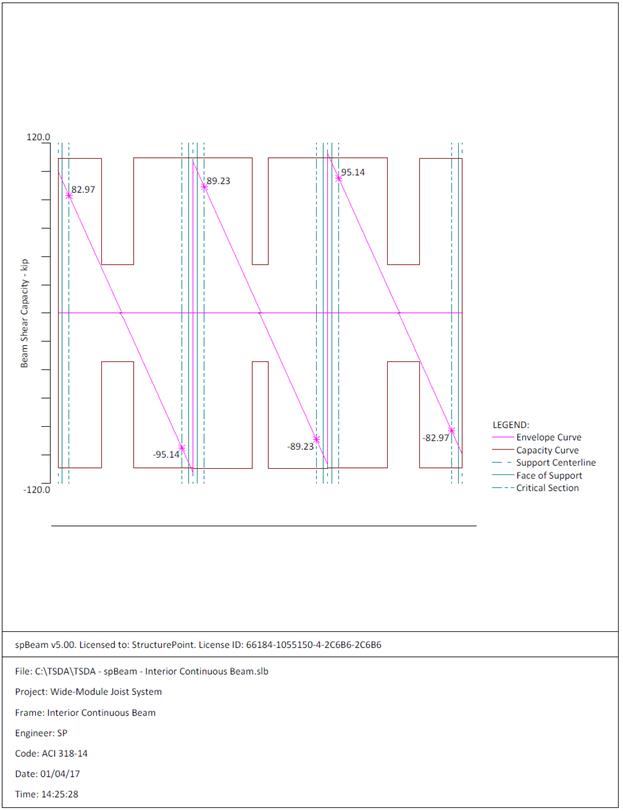

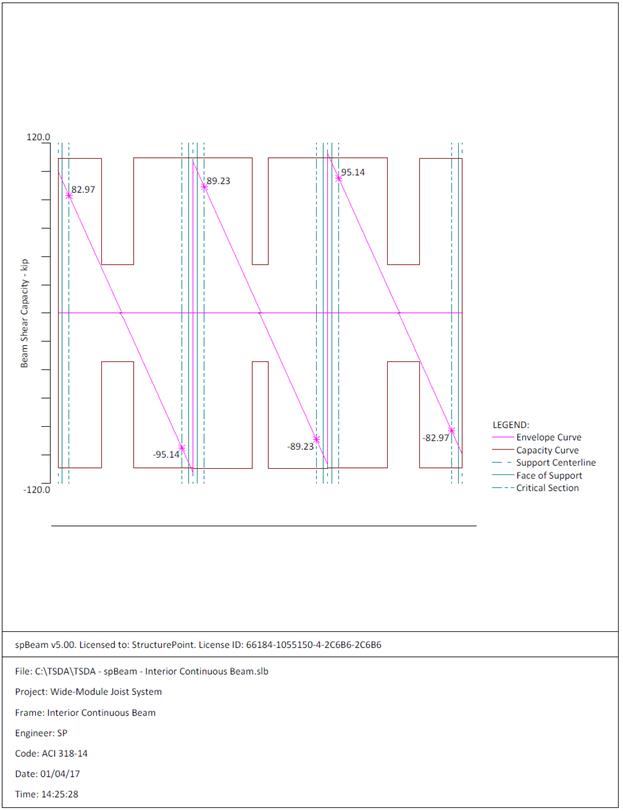

Figure 2.3.6.6 – spBeam Model – Shear Capacity Diagram

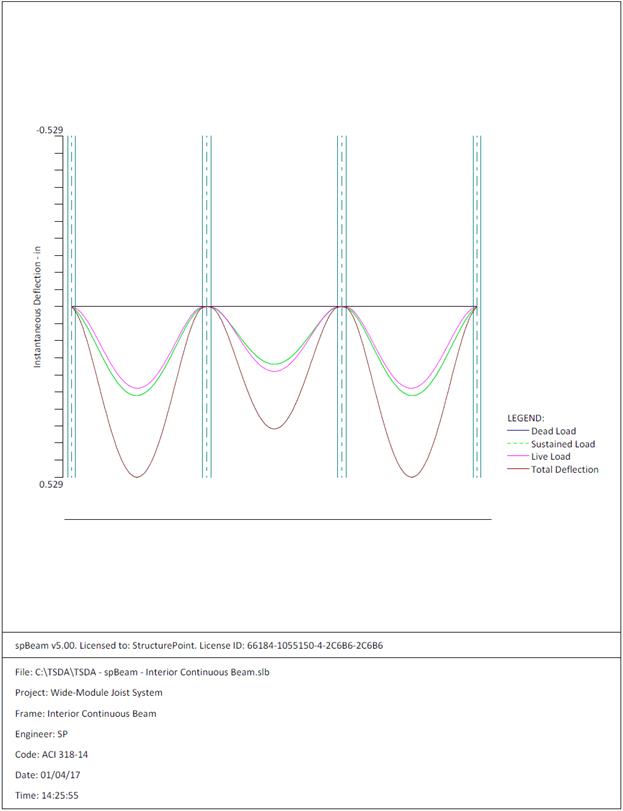

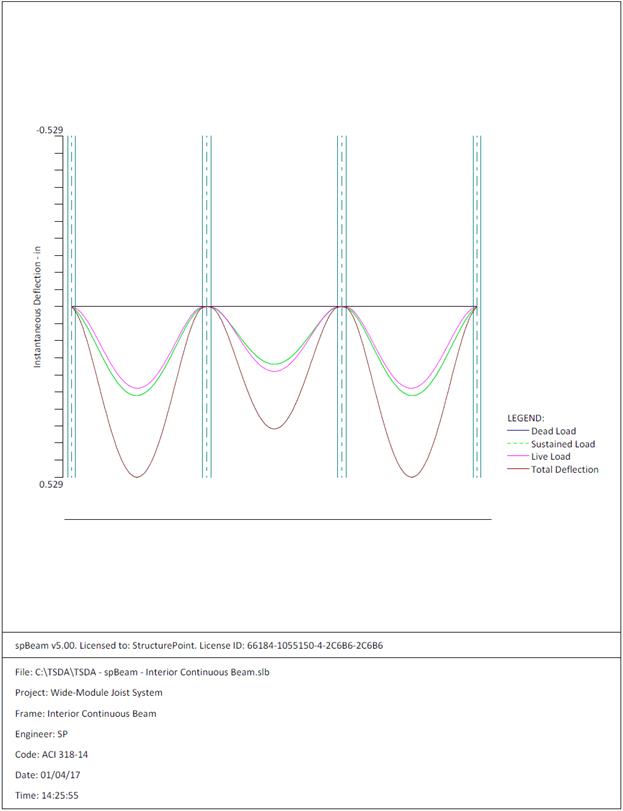

Figure 2.3.6.7 – spBeam Model – Immediate Deflection

Diagram

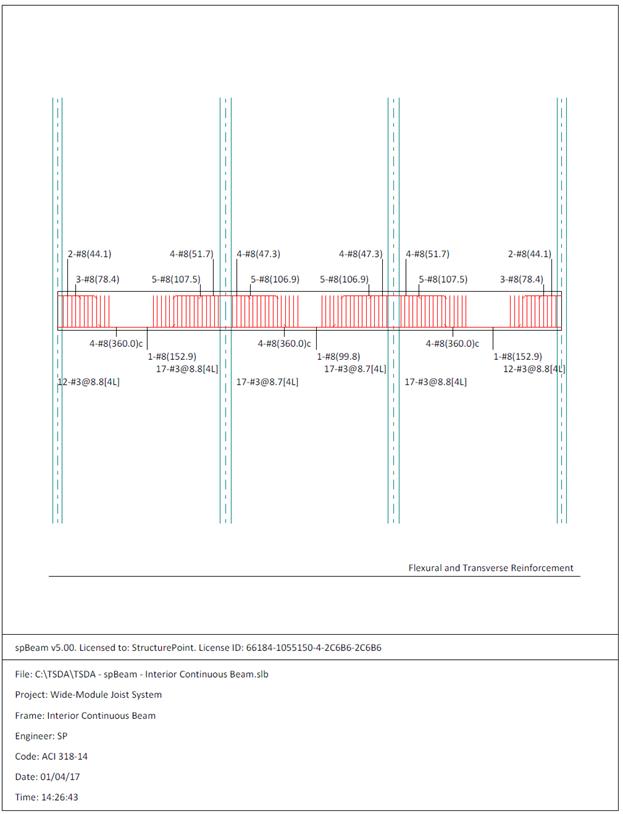

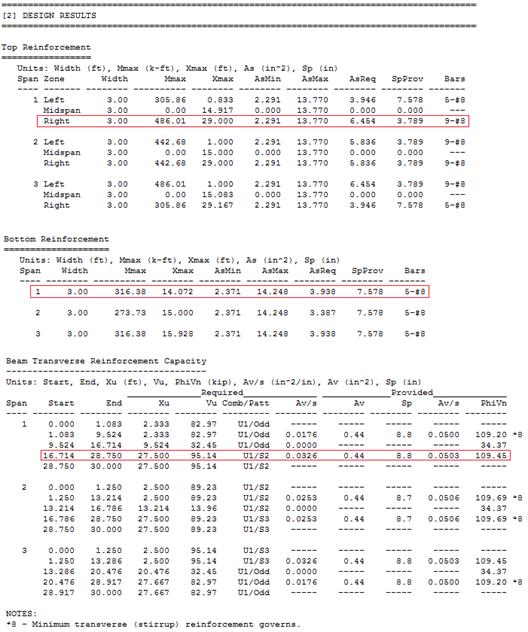

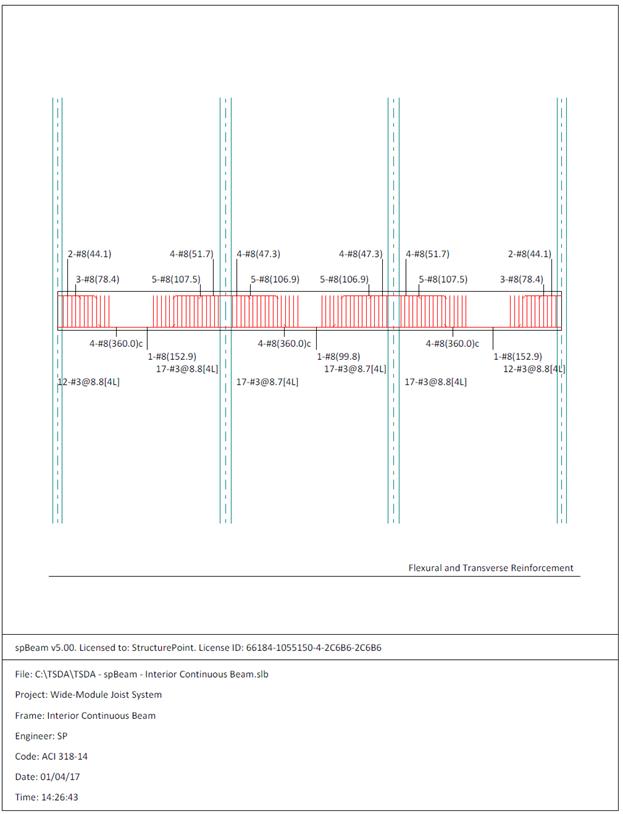

Figure 2.3.6.8 – spBeam Model – Reinforcement Diagram

|

Table 2.3.7.1

– Comparison of Hand Solution with spBeam Solution

|

|

Flexural

Design

|

|

Span

Location

|

Design Moment

(ft-kips)

|

Reinforcement

Required

for Flexure

(in2)

|

Reinforcement

Provided

for Flexure

(in2)

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

Interior

Negative

|

553.5

|

486.01

|

7.51

|

6.45

|

10-#8

|

9-#8

|

|

Positive

|

344

|

316.4

|

4.22

|

3.94

|

6-#8

|

5-#8

|

|

Shear Design

|

|

|

|

Span

Location

|

Vu

(kips)

|

φVn

(kips)

|

|

|

|

End Span

|

Hand

Solution

|

spBeam

Solution

|

Hand

Solution

|

spBeam

Solution

|

|

|

|

Interior

Negative

|

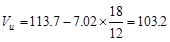

103.2

|

95.14

|

112.9

|

109.45

|

|

|

In this design example, the interior beam is modeled as a continuous

rectangular longitudinal beam. There is a good agreement between the hand

solution and computer solution. Note that the coefficients traditionally used

to determine moments do not address various types of support and geometry.

The maximum calculated total immediate (instantaneous) deflection (DL +

LL) = 0.529 in., this value can be compared with maximum permissible calculated

deflection limitation per project criteria in accordance to ACI 318-14.

ACI 318-14 (Table 24.2.2)

In addition to

deflection results, parametric studies can be performed in spBeam to optimize design and detailing

results.

The

reinforcement diagram (Figure 2.3.6.8) shows the minimum length required

(including the development length) for flexural design. The bars can be

extended and detailed to provide the required support for shear stirrups.

Figure 2.3.8 – Interior Beam Cross-Section (Near the First

Interior Support)

In the wide-module joist construction, the supporting beam depths shall

be same as the overall joist depth. Therefore, the beam depth is set to 21 in.

This beam depth need to satisfy the minimum depth requirement of ACI 318-14 (Table 9.3.1.1) so that the

deflection computations can be waived. The beams of the exterior frame shall be

designed and detailed for the combined effects of flexure, shear, and torsion

according to ACI 318.

Using the minimum depth for

non-prestressed beams in Table 9.3.1.1.

End Span:  in

(governs) < 21 in. ACI 318-14 (Table

9.3.1.1)

in

(governs) < 21 in. ACI 318-14 (Table

9.3.1.1)

Interior Span:  in

ACI 318-14 (Table 9.3.1.1)

in

ACI 318-14 (Table 9.3.1.1)

Therefore, the preliminary beam depth satisfies the

minimum depth requirement.

Figure

2.4 – Partial plan view showing interior beam along grid B

Beam (girder)

design involves the following steps:

2.4.1. Determination of span loads

2.4.2. Determination of design moment, shear, and torsion

2.4.3. Flexural and torsion design

2.4.4. Shear and torsion design

2.4.5. Deflections

2.4.6. Computer program solution

2.4.7. Summary and comparison of design results

2.4.8. Conclusions and observations

Dead

Load:

Try 24 in width

for the beam (slightly larger than the column width that helps facilitate the

forming, and reduces the beam longitudinal vs. column vertical bar

interference)

Joist & Slab

Weight  kips/ft

kips/ft

Beam Weight kips/ft

kips/ft

Superimposed

Dead Load, SDL  kips/ft

kips/ft

Live

Load:

Check

for live load reduction per ASCE/SEI

7-10

ASCE/SEI 7-10 (Eq. 4-1)

ASCE/SEI 7-10 (Eq. 4-1)

Where:

reduced

design live load per ft2 of area supported by the member

reduced

design live load per ft2 of area supported by the member

unreduced

design live load per ft2 of area supported by the member = 80 psf

unreduced

design live load per ft2 of area supported by the member = 80 psf

2

(edge beams without cantilever slabs)

ASCE/SEI 7-10 (Table 4-2)

2

(edge beams without cantilever slabs)

ASCE/SEI 7-10 (Table 4-2)

tributary

area

tributary

area  ft2

ft2

psf

psf

Which

satisfies  requirement for members supporting one floor. ASCE/SEI

7-10 (4.7.2)

requirement for members supporting one floor. ASCE/SEI

7-10 (4.7.2)

kips/ft

kips/ft

Load

Combination:

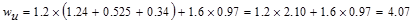

The following gravity load combinations are

considered:

ACI 318-14 (Eq. 5.3.1a)

ACI 318-14 (Eq. 5.3.1a)

kips/ft

kips/ft

ACI 318-14 (Eq. 5.3.1b)

ACI 318-14 (Eq. 5.3.1b)

kips/ft

kips/ft

The span loads are governed by the

second load combination.

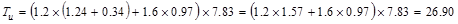

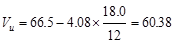

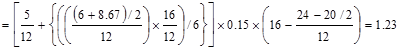

For factored torsional moment

calculations, the beam self-weight is not included since it is applied along

the beam section centerline. And the moment arm is the distance from the midspan

to the centerline of the exterior beam section = 16/2 – (24/2 - 20/2)/12 = 7.83

ft.

Thus,

the following load combinations are used for the calculation of the factored

torsional moment:

ACI

318-14 (Eq. 5.3.1a)

ACI

318-14 (Eq. 5.3.1a)

kips.ft/ft

kips.ft/ft

ACI 318-14 (Eq. 5.3.1b)

ACI 318-14 (Eq. 5.3.1b)

kips.ft/ft

kips.ft/ft

The span factored torsional moments

are governed by the second load combination.

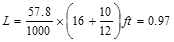

The factored moment and shear can

be determined using the simplified method if the requirements are

satisfied:

ACI 318-14 (6.5.1)

ü Members are prismatic.

ü Loads are uniformly distributed.

ü L ≤ 3D (0.97 kips/ft ≤

3 x 2.10 kips/ft)

ü There are at least two spans.

ü The longer of two adjacent spans does

not exceed the shorter by more than 20 percent.

Thus, the

approximate coefficients can be used. The factored moments and shears are

determined and summarized in the following

tables. ACI 318-14

(Table 6.5.2 and Table 6.5.3)

|

Table 2.4.2.1

– Exterior Beam Design Flexural Moment Values

|

|

Location

|

Design Flexural

Moment Value

|

|

End Spans

|

Exterior Support Negative

|

ft-kips ft-kips

|

|

Mid-span

|

ft-kips ft-kips

|

|

Interior Support Negative

|

ft-kips ft-kips

|

|

Interior Spans

|

Mid-span Positive

|

ft-kips ft-kips

|

|

Support Negative

|

ft-kips ft-kips

|

|

Table 2.4.2.2

– Exterior Design Shear Values

|

|

Location

|

Design Shear

Value

|

|

End Span at Face of First Interior

Support

|

kips kips

|

|

At Face of all other Supports

|

kips kips

|

Any structural

analysis method can be used to calculate the torsional. The following table

shows the torsional moment values at the centerline of the supports:

|

Table 2.4.2.3

– Exterior Design Torsional Moment Values

|

|

Location

|

Design Torsional

Moment Value

|

|

At the centerline of all Supports

|

ft-kips ft-kips

|

For this exterior beam, the end span moment values

govern the design as tabulated in Table 2.4.2.1.

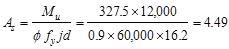

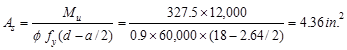

Calculate the required reinforcement to resist the first interior support

negative moment:

ft-kips

ft-kips

Use #8 bars with 1.5 in. concrete cover per ACI

318-14 (Table 20.6.1.3.1). To avoid interference with joist

negative moment reinforcement, the clear cover to the girder top reinforcement

is required to be increased by lowering the girder top reinforcement. The distance from extreme compression fiber to the

centroid of longitudinal tension reinforcement, d, is calculated below:

To determine the area of steel,

assumptions have to be made whether the section is tension or compression controlled,

and regarding the distance between the resultant compression and tension forces

along the slab section (jd). In this example, tension-controlled section

will be assumed so the reduction factor is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a rectangular beam (narrow compression

zone). The assumptions will be verified once the area of steel is finalized.

is

equal to 0.9, and jd will be taken equal to 0.9d since we are

designing for the negative moment in a rectangular beam (narrow compression

zone). The assumptions will be verified once the area of steel is finalized.

Assume in.

in.

Interior

beam width,  in.

in.

The required reinforcement at initial

trial is calculated as follows:

in.2

in.2

Recalculate

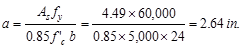

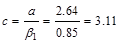

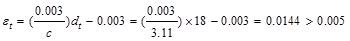

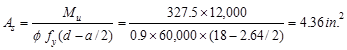

‘a’ for the actual As = 4.49 in.2:

in.

in.

Therefore,

the assumption that section is tension-controlled is valid.

The

minimum reinforcement shall not be less than

ACI 318-14

(9.6.1.2(a))

ACI 318-14

(9.6.1.2(a))

And

not less than

ACI 318-14 (9.6.1.2(b))

ACI 318-14 (9.6.1.2(b))

All the values on the following

table are calculated based on the procedure outlined above.

|

Table 2.4.3.1

– Reinforcing Design Summary (Flexure only)

|

|

|

End Span

|

Interior Span

|

|

|

Exterior

Negative

|

Positive

|

Interior

Negative

|

Positive

|

Negative

|

|

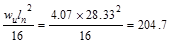

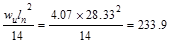

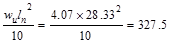

Design Moment, Mu

(ft-kips)

|

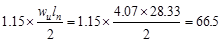

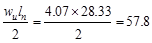

204.7

|

233.9

|

327.5

|

204.7

|

297.7

|

|

Effective depth,

d (in.)

|

18.0*

|

18.625**

|

18.0*

|

18.625**

|

18.0*

|

|

As, req’d

(in.2)

|

2.65

|

2.93

|

4.36

|

2.55

|

3.94

|

|

As, min

(in.2)

|

1.53

|

1.58

|

1.53

|

1.58

|

1.53

|

|

* The beam top bars are to be placed below the joist top

bars.

|

|

** The beam bottom bars are to be placed at the bottom-most

layer. The joist bottom bars, then, shall be spliced at

joist-beam intersection.

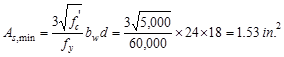

|

Torsion requirements for

longitudinal steel have to be determined and combined with reinforcement area

required for flexure.

Calculate the required reinforcement to resist torsion:

Check if

torsional effects can be neglected:

If Tu

< φTth, it shall be permitted to neglect

torsional effects. ACI 318-14

(22.7.1.1)

Where:

ft-kips

ft-kips

ft-kips

= Threshold torsion (the calculation of φTth is shown in

the next section)

ft-kips

= Threshold torsion (the calculation of φTth is shown in

the next section)

Since Tu > φTth, the

torsional effects must be considered.

Check if the

factored design torsion can be reduced:

It is permitted

to reduce Tu to φTcr; due to

redistribution of internal forces after torsional cracking; if the exterior

continuous beam meet the following

requirements: ACI 318-14

(22.7.3.2)

1. The beam is statically indeterminate (continuous beam).

2. Tu ≥ φTcr.

To check the

second condition, φTcr need to be calculated as follows:

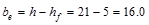

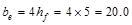

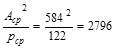

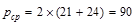

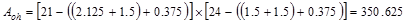

Since the beams are cast monolithically with slab and joists, Acp

(area enclosed by outside perimeter of concrete cross section) and pcp

(outside perimeter of concrete cross section) for the beam can include a

portion of the adjoining slab. The effective width, be, of

the overhanging flange must conform to ACI 318-14 (8.4.1.8):

in.

(governs)

in.

(governs)

in.

in.

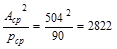

in.2

in.2

in.

in.

in.3

in.3

The torsional

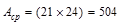

properties of the beam ignoring the overhanging flange are the following:

in.2

in.2

in.

in.

in.3

> 2796 in.3

in.3

> 2796 in.3

Therefore,

consider the rectangular

section. ACI

318-14 (9.2.4.4(b))

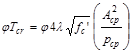

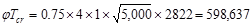

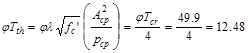

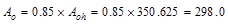

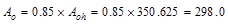

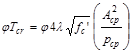

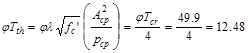

ACI 318-14 (Table 22.7.5.1(a))

ACI 318-14 (Table 22.7.5.1(a))

in.-lbs

= 49.9 ft-kips

in.-lbs

= 49.9 ft-kips

ft-kips

ft-kips

Checking the

second condition of ACI 318-14 (22.7.3.2):

ft-kips

>

ft-kips

>  ft-kips

ft-kips

Thus, ACI

318-14 permits to reduce Tu to φTcr.

ft-kips

ACI 318-14 (22.7.3.2)

ft-kips

ACI 318-14 (22.7.3.2)

It is assumed

that the torsional loading on the beam is uniformly distributed along the span.

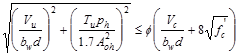

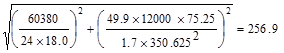

Determine the adequacy of cross-sectional

dimensions for the torsion:

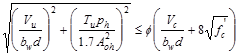

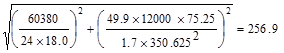

For solid sections, the limit on

shear and torsion is given by:

ACI 318-14 (22.7.7.1)

ACI 318-14 (22.7.7.1)

Where:

Aoh = area enclosed by centerline of outermost closed

transverse torsional reinforcement.

ph = perimeter of centerline of outermost closed

transverse torsional reinforcement.

Using d = 18.0 in., the

factored shear force at the critical section located at a distance d

from the face of the support is:

kips.

kips.

Also, the nominal shear strength

provided by the concrete is:

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

Using a 1.5-in. clear cover to # 3

closed stirrups at bottom and 2.125 in clear cover to # 3 closed stirrups at

top.

in2

in2

in

in

psi

psi psi

psi

Therefore, the

section is adequate.

Determine the transverse

reinforcement required for torsion:

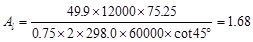

ACI 318-14 (Eq. 22.7.6.1a)

ACI 318-14 (Eq. 22.7.6.1a)

Where

in2

ACI

318-14 (22.7.6.1.1)

in2

ACI

318-14 (22.7.6.1.1)

ACI 318-14 (22.7.6.1.2(a))

ACI 318-14 (22.7.6.1.2(a))

Therefore,

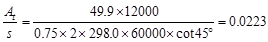

in2

/ in per leg

in2

/ in per leg

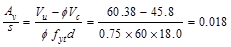

Determine the transverse

reinforcement required for shear:

From Table 2.3.2.2 above, the

maximum shear value occurs at the face of the first interior support in the end

span.

kips

kips

The design shear at a distance, d,

away from the face of support,

kips

kips

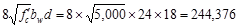

Shear strength provided by concrete

ACI 318-14 (Eq. 22.5.5.1)

ACI 318-14 (Eq. 22.5.5.1)

lb

lb

kips

kips

Since ,

shear reinforcement is required.

,

shear reinforcement is required.

The nominal shear strength required

to be provided by shear reinforcement is

kips

kips

Check whether Vs

is less than

If Vs is greater

than ,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to

,

then the cross-section has to be revised as ACI 318-14

limits the shear capacity to be provided by stirrups to .

ACI 318-14 (22.5.1.2)

.

ACI 318-14 (22.5.1.2)

lb

lb

kips

kips

Since Vs does not

exceed .

The cross-section is adequate.

.

The cross-section is adequate.

Calculate the required transverse

reinforcement for shear as

in.2/in.

ACI 318-14

(22.5.10.5.3)

in.2/in.

ACI 318-14

(22.5.10.5.3)

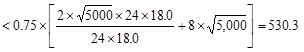

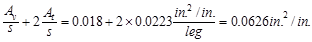

Calculate total required

transverse reinforcement for combined shear and torsion:

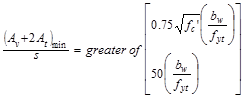

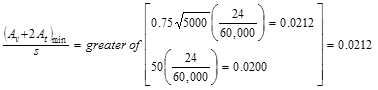

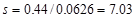

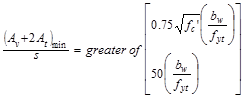

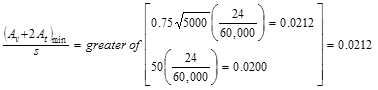

Minimum transverse reinforcement

for shear and torsion is calculated as follows:

ACI 318-14 (9.6.4.2)

ACI 318-14 (9.6.4.2)

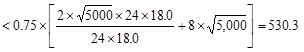

in.2/in.

< 0.0626 in.2/in.

in.2/in.

< 0.0626 in.2/in.

Then, provide

Calculate the required spacing:

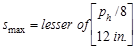

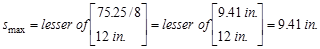

Maximum spacing of transverse

torsion reinforcement:

ACI 318-14 (9.7.6.3.3)

ACI 318-14 (9.7.6.3.3)

Maximum spacing of transverse shear

reinforcement:

Check whether the

required spacing based on the shear demand meets the spacing limits for shear

reinforcement per ACI 318-14

(9.7.6.2.2).

Check whether Vs

is less than

lb

lb

kips

> Vs = 19.43 kips

kips

> Vs = 19.43 kips

Therefore,

maximum stirrup spacing shall be the smallest of d/2 and 24 in.

ACI 318-14 (Table 9.7.6.2.2)

ACI 318-14 (Table 9.7.6.2.2)

(governs)

(governs)

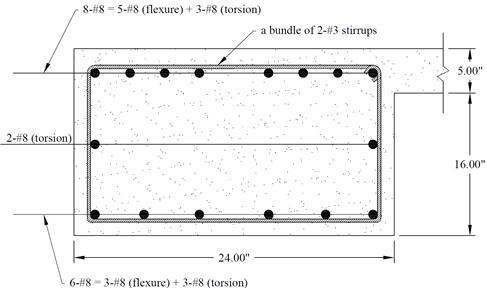

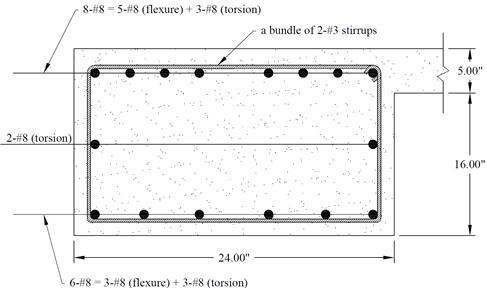

Using a bundle of 2-#3 closed

stirrups with 2 legs (area per leg  in2),

the required spacing, s, at the critical section is:

in2),

the required spacing, s, at the critical section is:

in

in

in

in

Provide a bundle

of 2-#3 closed stirrups with 2 legs spaced at 7 in. on center. #3 bars are

selected for consistency with the transverse reinforcement size used for the

joist and interior beam. The stirrups are bundled at outer legs to maintain A0

value in calculation of At/s for torsion. The bundle of 2-#3 bars

are defined as user-defined reinforcement of size #2 in spBeam Program.

The designer may

choose to utilize #4 closed stirrups with 2 legs at 6 in. on center

alternatively.

In view of the shear and torsion distribution along the span length, this

same reinforcement and spacing can be provided throughout the span length.

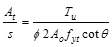

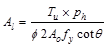

Calculate the

additional required longitudinal reinforcement for torsion:

ACI 318-14 (Eq. 22.7.6.1b)

ACI 318-14 (Eq. 22.7.6.1b)

Where

in.2

ACI 318-14 (22.7.6.1.1)

in.2

ACI 318-14 (22.7.6.1.1)

ACI 318-14 (22.7.6.1.2(a))

ACI 318-14 (22.7.6.1.2(a))

Therefore,

in.2

in.2

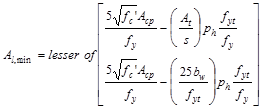

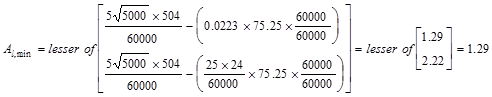

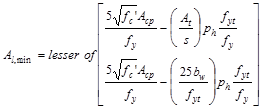

The minimum

total area of longitudinal torsional reinforcement:

ACI 318-14 (9.6.4.3)

ACI 318-14 (9.6.4.3)

in.2

in.2

Since Al > Al,min,

use Al = 1.68 in.2

The longitudinal

reinforcement is to be distributed around the perimeter of the stirrups, with a

maximum spacing of 12 in. There shall be at least one longitudinal bar

in each corner of the stirrups.

ACI318-14 (9.7.5.1)

Longitudinal

bars shall have a diameter at least 0.042 times the stirrup spacing, but

not less than 3/8 in.

ACI318-14 (9.7.5.2)

To meet the

maximum spacing requirement, a bar has to be provided between corner bars at

all four sides. This configuration leads to eight-bars; three at top, three at

bottom, and one at each side. Therefore, the reinforcement area per bar is As

= 1.68/8 = 0.21 in.2

Then, use #5 bars for longitudinal bars which also meets minimum

bar diameter requirement of 3/8 in. Al shall be

provided in addition to the required flexural reinforcement at the negative

moment regions (support-top) and positive moment region (mid-span-bottom). At

mid-span-top region where flexural reinforcement is not required for flexure, 3-#5

bars shall be provided. Class B lap splice is to be provided.

|

Table 2.4.3.2 – Reinforcing Design Summary (Flexure + Torsion)

|

|

|

End Span

|

Interior Span

|

|

|

Top

Reinforcing for Exterior Negative Moment

|

Bottom

Reinforcing for Positive Moment

|

Top

Reinforcing for Interior Negative Moment

|

Bottom

Reinforcing for Positive Moment

|

Top

Reinforcing for Interior Negative Moment

|

|

Required

Longitudinal Reinforcement (in.2)

|

2.65

|

2.93

|

4.36

|

2.55

|

3.94

|

|

Required

Torsional Longitudinal Reinforcement (in.2)

|

0.63

|

0.63

|

0.63

|

0.63

|

0.63

|

|

Required

Total Longitudinal Reinforcement (in.2)

|

3.28

|

3.56

|

4.99

|

3.18

|

4.57

|

|

Reinforcement

|

5-#8

|

5-#8

|

7–#8

|

4-#8

|

6-#8

|

Maximum spacing allowed:

Check the requirement for

distribution of flexural reinforcement to control flexural cracking:

ACI 318-14 (Table 24.3.2)

ACI 318-14 (Table 24.3.2)

in.

in.

Use  ksi

ACI

318-14 (24.3.2.1)

ksi

ACI

318-14 (24.3.2.1)

in.

(governs)

in.

(governs)

in.

in.

Spacing provided for 4-# 8 bars

in.

in.

in.

o.k.

in.

o.k.

Where ds = 2.625

in. for #3

stirrup.

CRSI 2002 (Figure 12-9)

Check the spacing, s provided, is

greater than the minimum center to center spacing, smin where

CRSI 2002 (Figure 12-9)

CRSI 2002 (Figure 12-9)

Where maximum aggregate size is ¾”

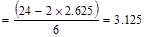

Spacing provided for 7-# 8 bars

in.

in.

in.

o.k.

in.

o.k.

Therefore, the reinforcement

selections in the previous table meet the spacing requirements.

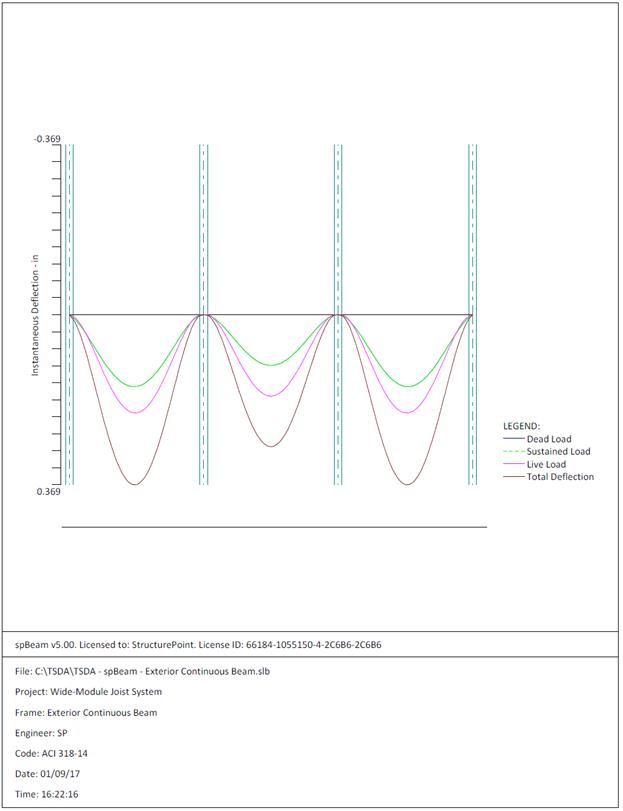

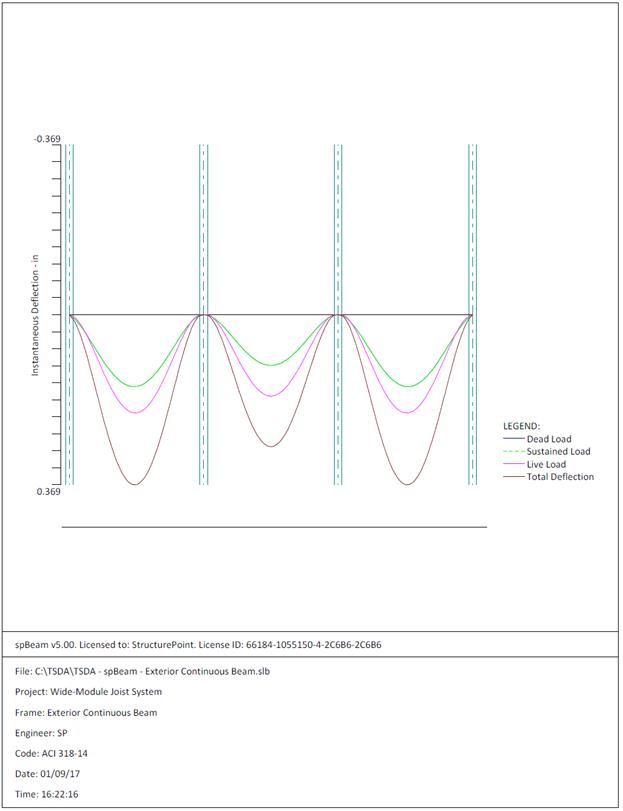

Since the preliminary beam depth met minimum depth requirement, the

deflection calculations are not required. A lesser depth maybe possible and

consequently cost savings can be achieved through deflection computations.

Deflection values are calculated and provided for every model created by spBeam

Program and can be used by the engineer to make additional optimization

decisions.

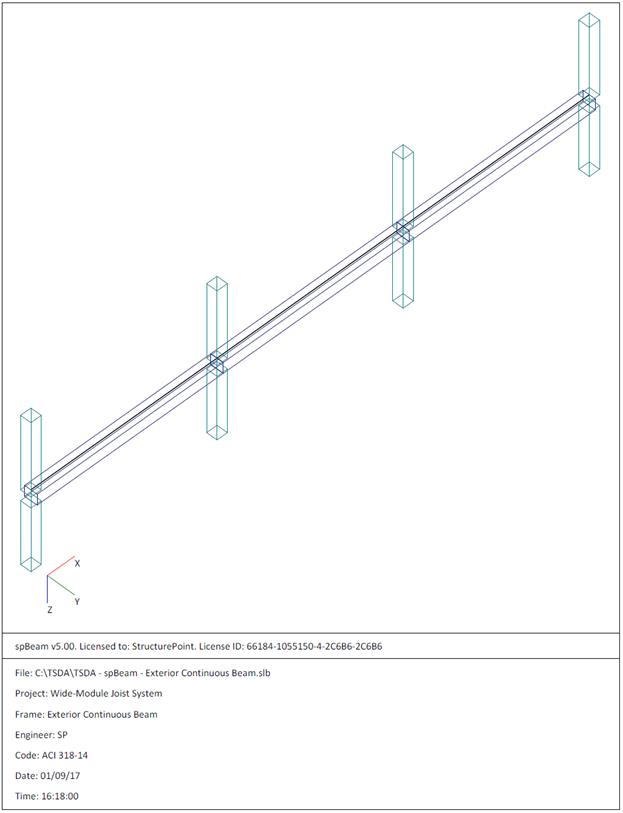

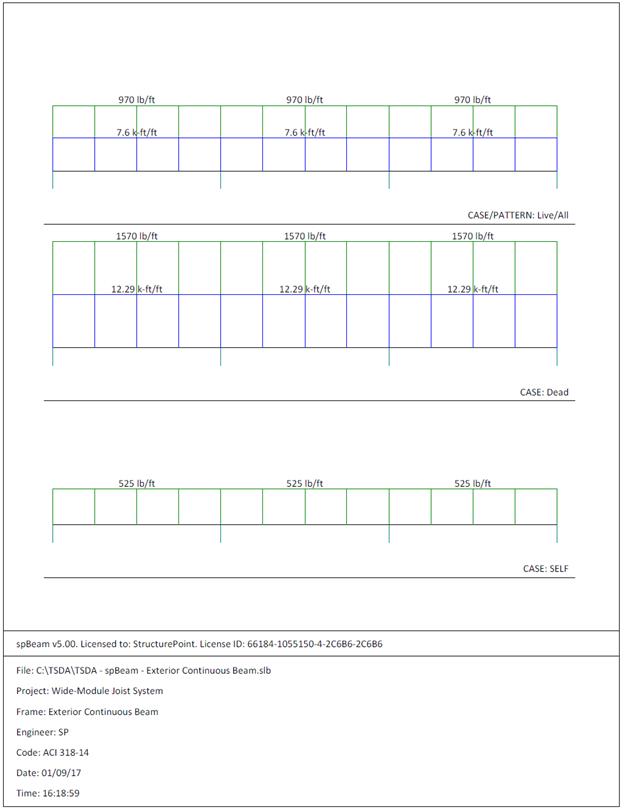

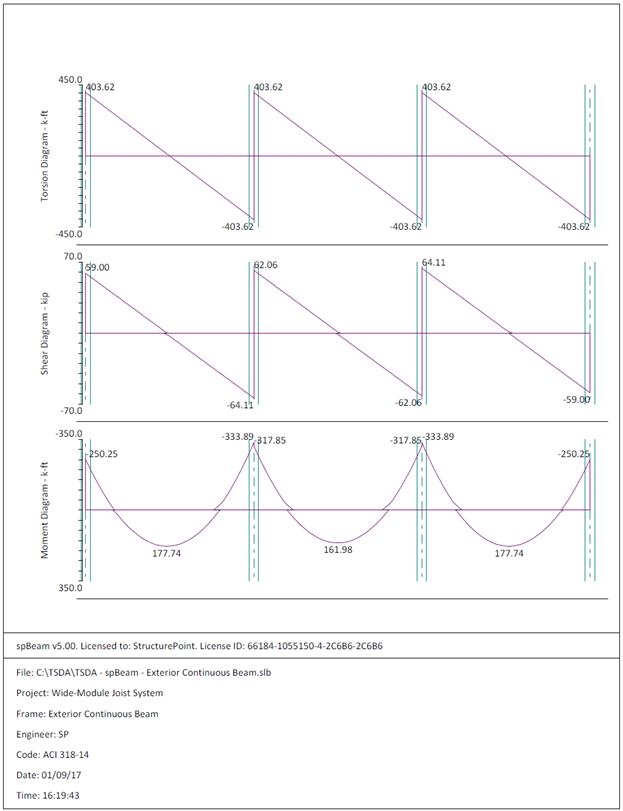

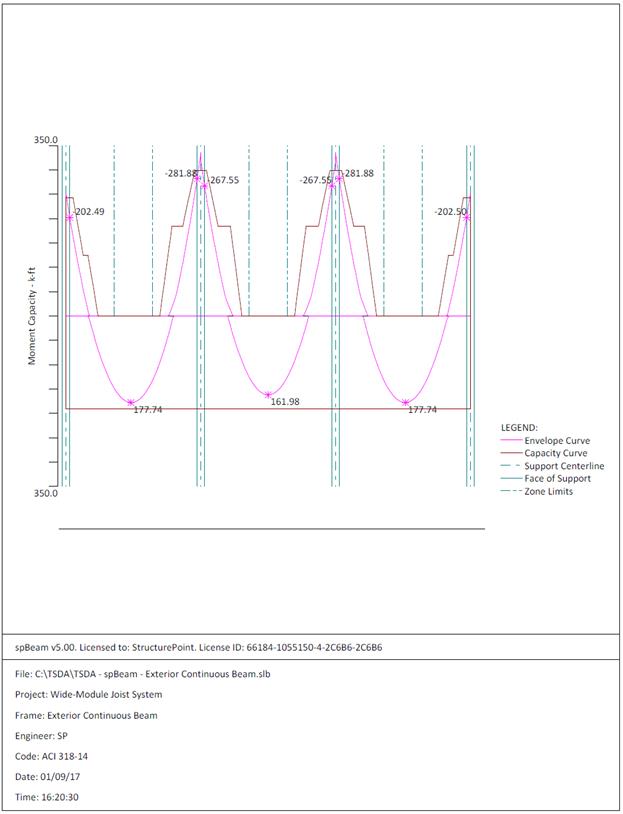

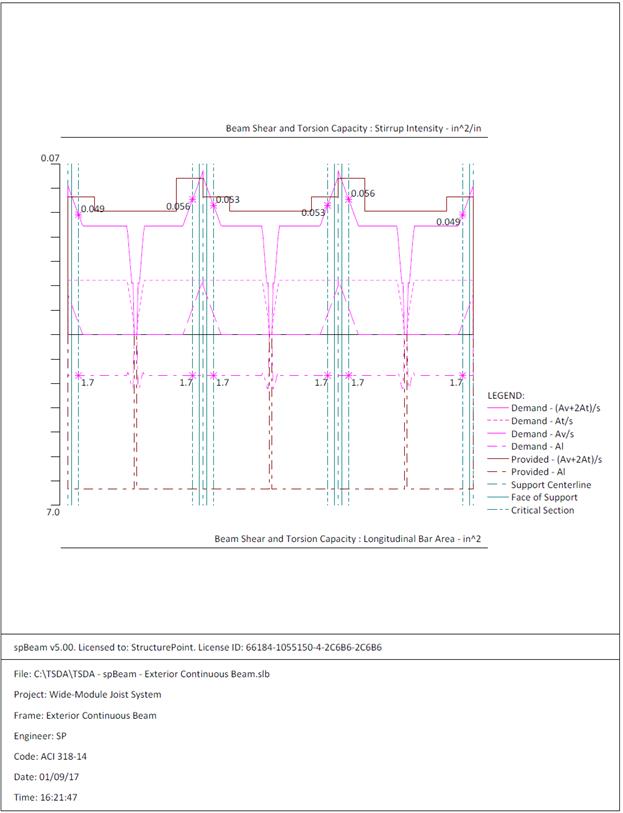

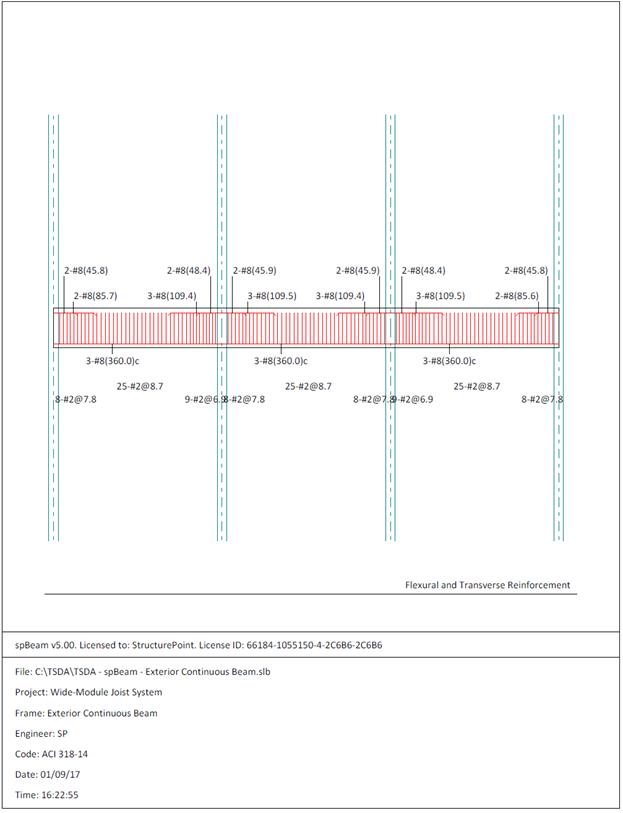

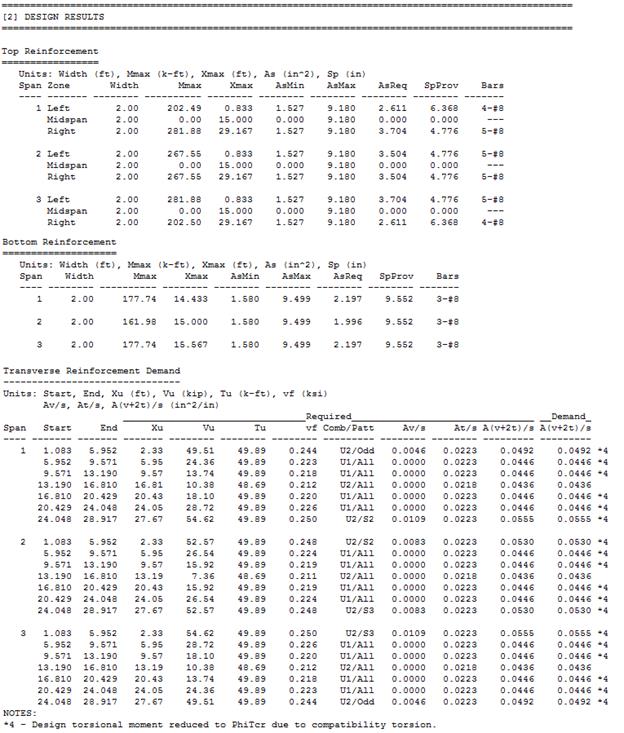

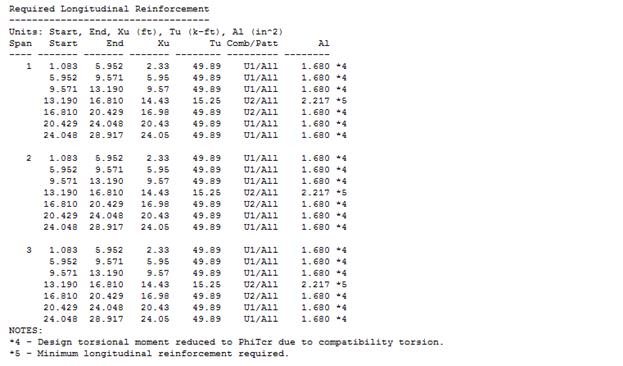

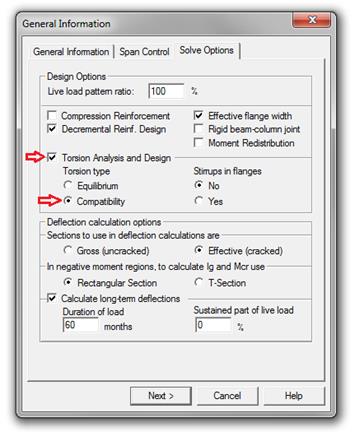

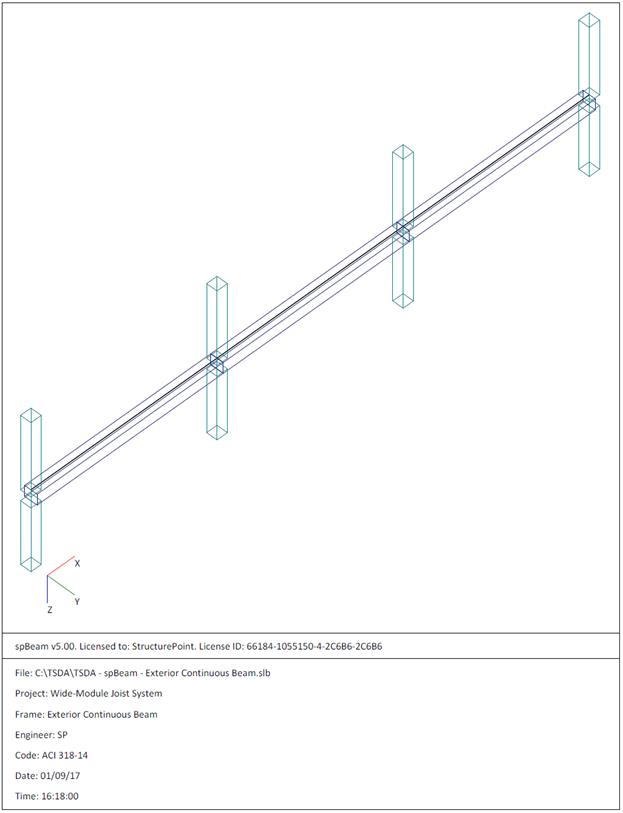

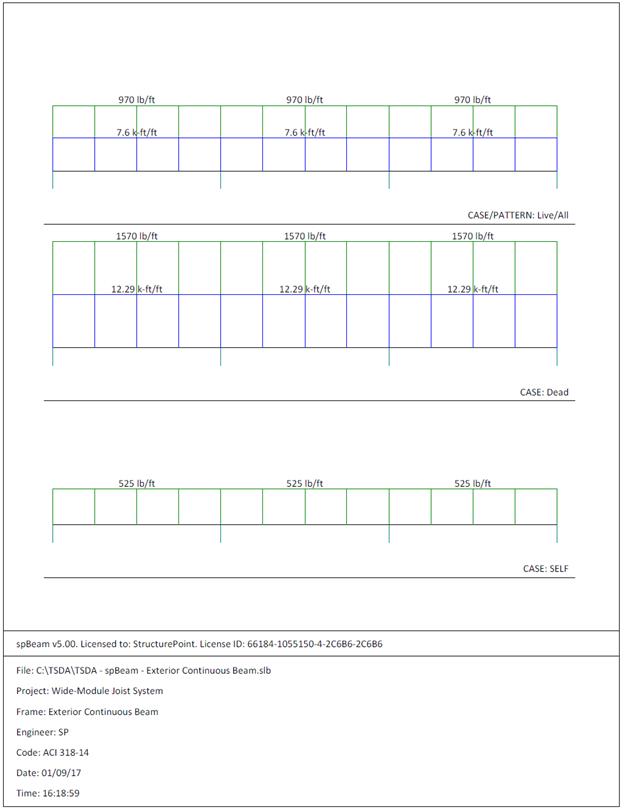

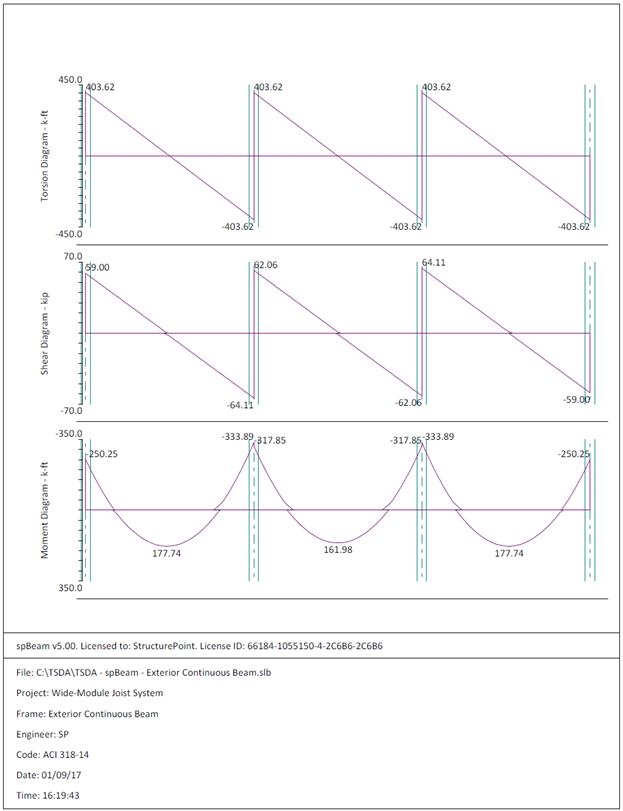

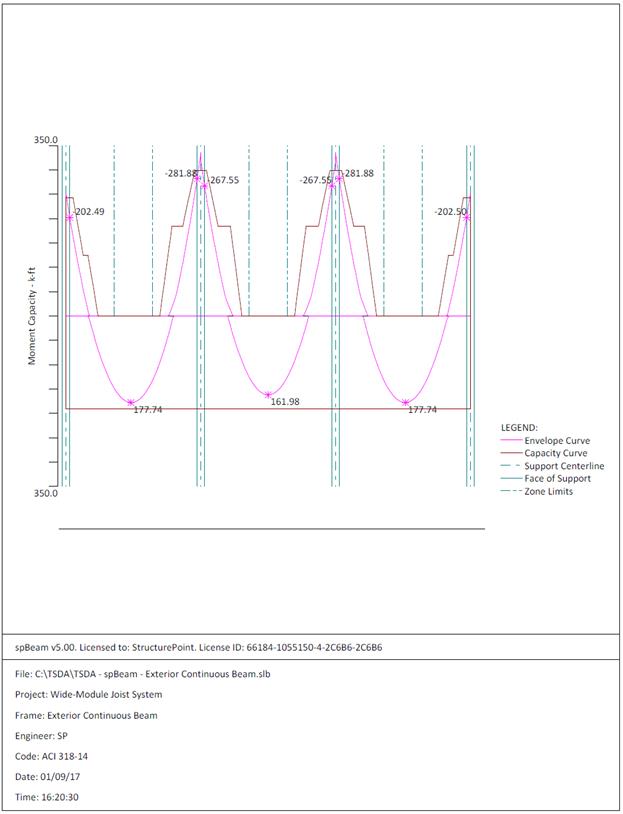

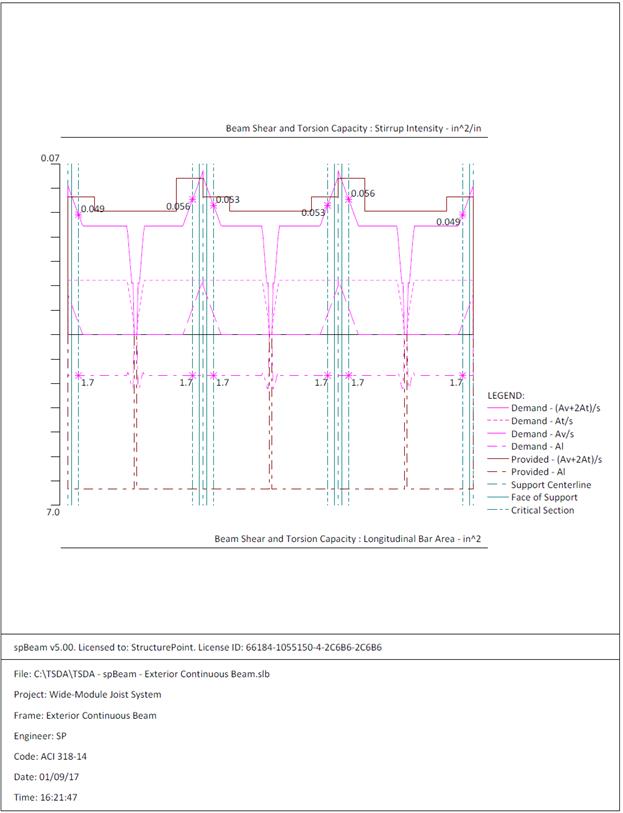

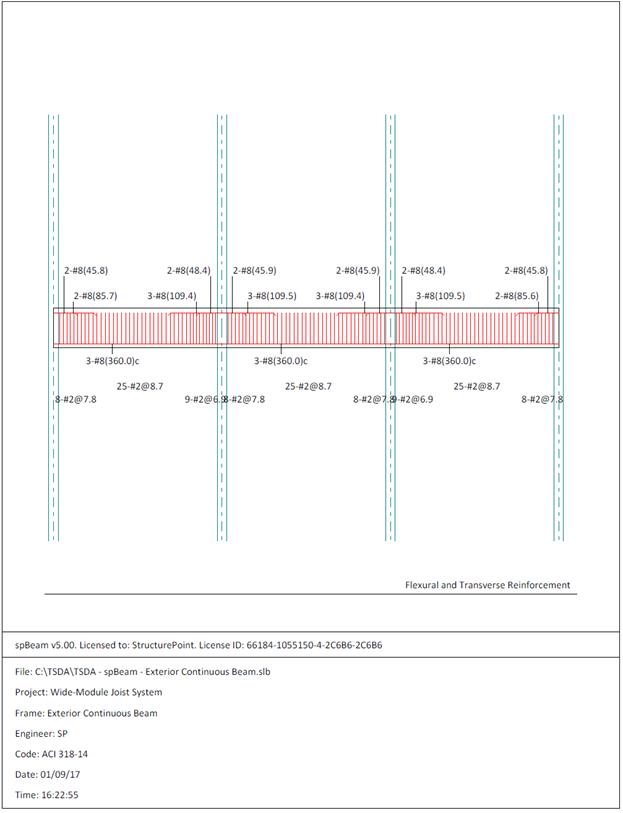

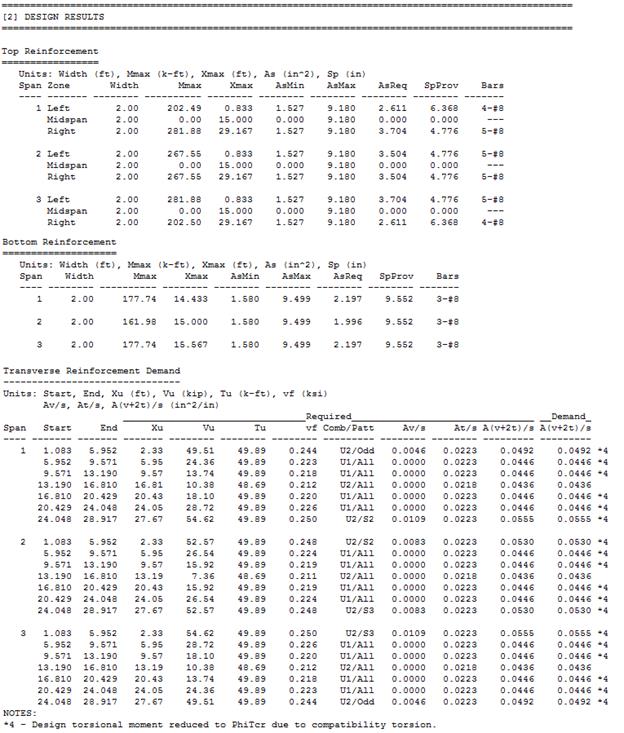

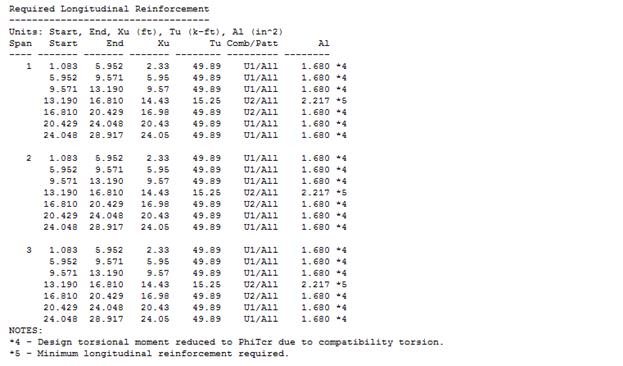

spBeam

Program can be utilized to analyze and design the exterior continuous beam

along grid A. The beam is modeled as a three span continuous rectangular beam.

The program

calculates the internal forces (shear force and bending moment), moment and

shear capacities, immediate and long-term deflection results, and required

flexural reinforcement. The graphical and text results are provided here for

both input and output of the spBeam model.

The beam is

modeled as a 24 in. by 21 in. deep rectangular longitudinal beam with column

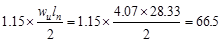

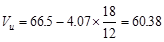

supports at 100% stiffness share.