1.1. Preliminary Flat Plate (without Joists)

1.1.1. Slab Minimum Thickness - Deflection

ACI 318-14 (Table 8.3.1.1) |

In lieu of detailed calculation for deflections, ACI 318 Code gives minimum slab thickness for two-way construction without interior beams in Table 8.3.1.1.

For flat plate slab system, the minimum slab thickness per ACI 318-14 are:

Exterior Panels: | ACI 318-14 (Table 8.3.1.1) |

But not less than 5 in. | ACI 318-14 (8.3.1.1(a)) |

Interior Panels: | ACI 318-14 (Table 8.3.1.1) |

But not less than 5 in. | ACI 318-14 (8.3.1.1(a)) |

Where ln = length of clear span in the long direction = 33 × 12 – 20 = 376 in.

Use 13 in. slab for all panels (self-weight = 150 pcf × 13 in. / 12 = 162.50 psf)

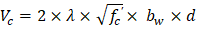

1.1.2. Slab Shear Strength - One Way Shear

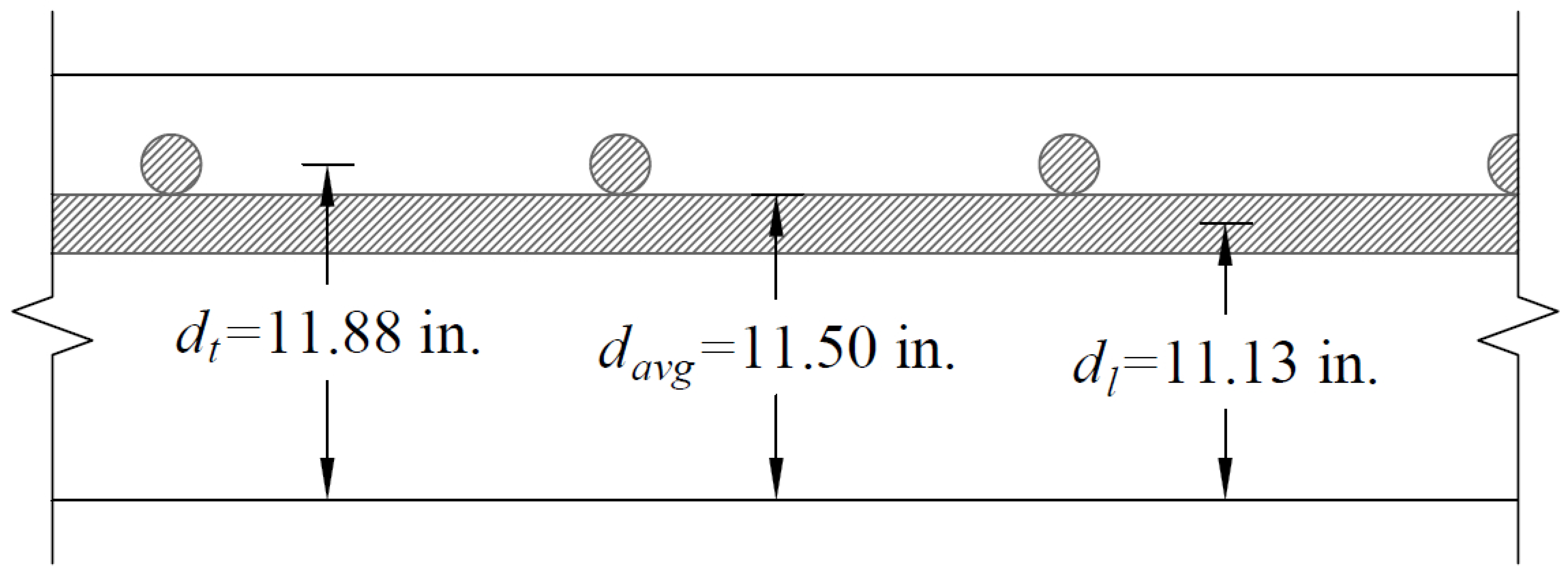

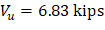

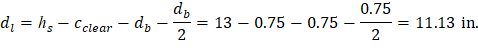

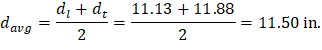

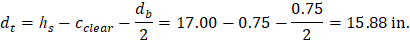

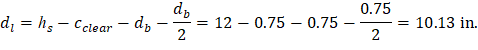

Evaluate the average effective depth (Figure 2):

| |

| |

|

Where:

cclear = 3/4 in. for # 6 steel bar | ACI 318-14 (Table 20.6.1.3.1) |

db = 0.75 in. for # 6 steel bar |

Figure 2 – Average Effective Depth for Flat Plate

Factored dead load, | ||

Factored live load, | ACI 318-14 (5.3.1) | |

Total factored load, |

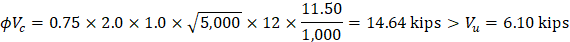

Check the adequacy of slab thickness for beam action (one-way shear) | ACI 318-14 (22.5) |

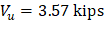

At an interior column:

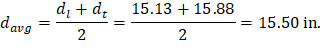

Consider a 12-in. wide strip. The critical section for one-way shear is located at a distance d, from the face of support (see Figure 3).

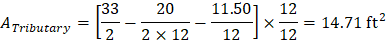

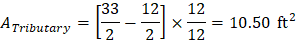

Tributary area for one-way shear is:

| |

| |

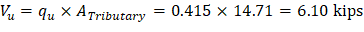

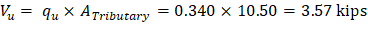

| ACI 318-14 (Eq. 22.5.5.1) |

where λ = 1 for normal weight concrete, more information can be found in “Concrete Type Classification Based on Unit Density” technical article.

Slab thickness of 13 in. is adequate for one-way shear.

Figure 3 – Critical Section for One-Way Shear

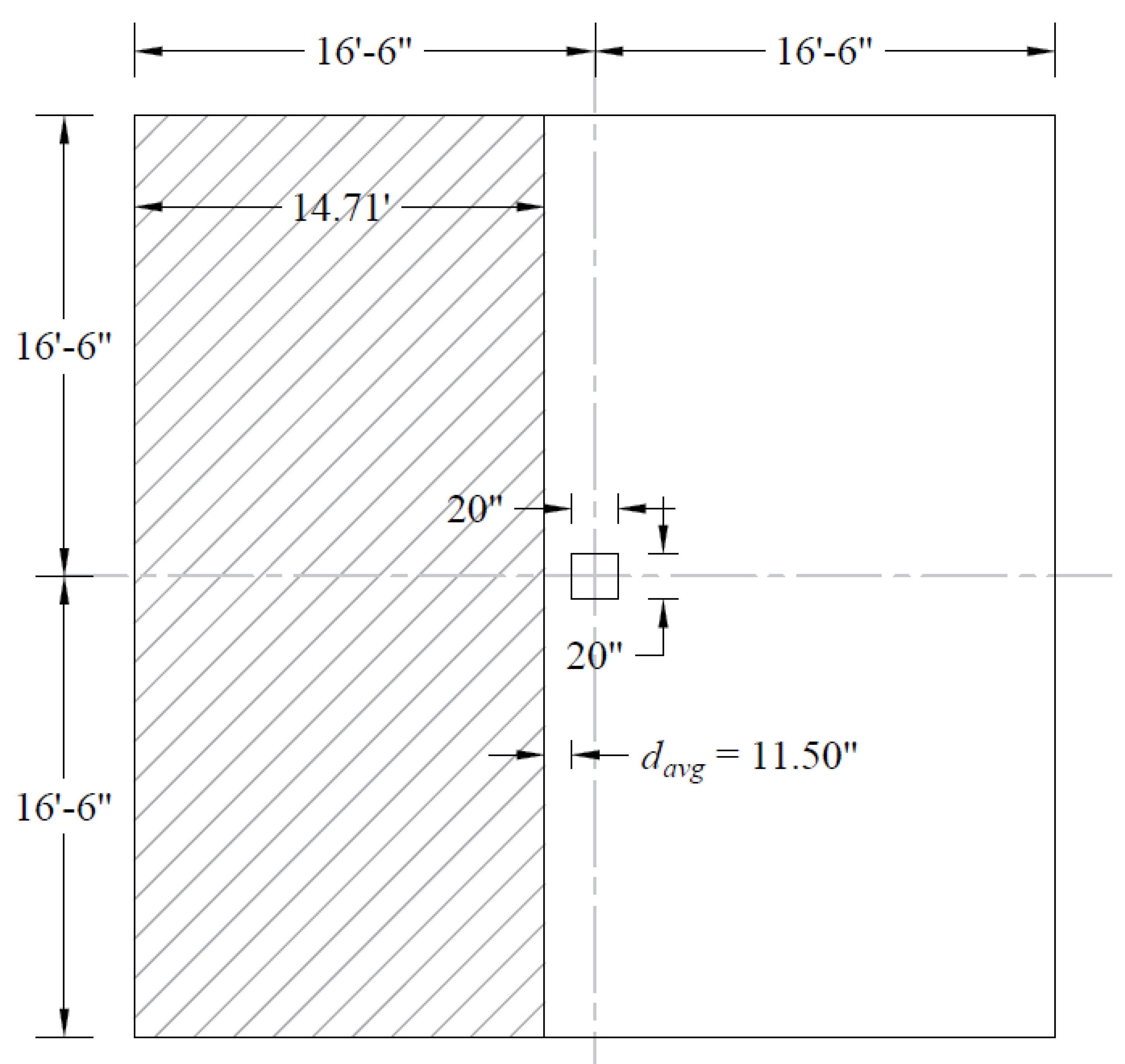

1.1.3. Slab Shear Strength - Two-Way Shear

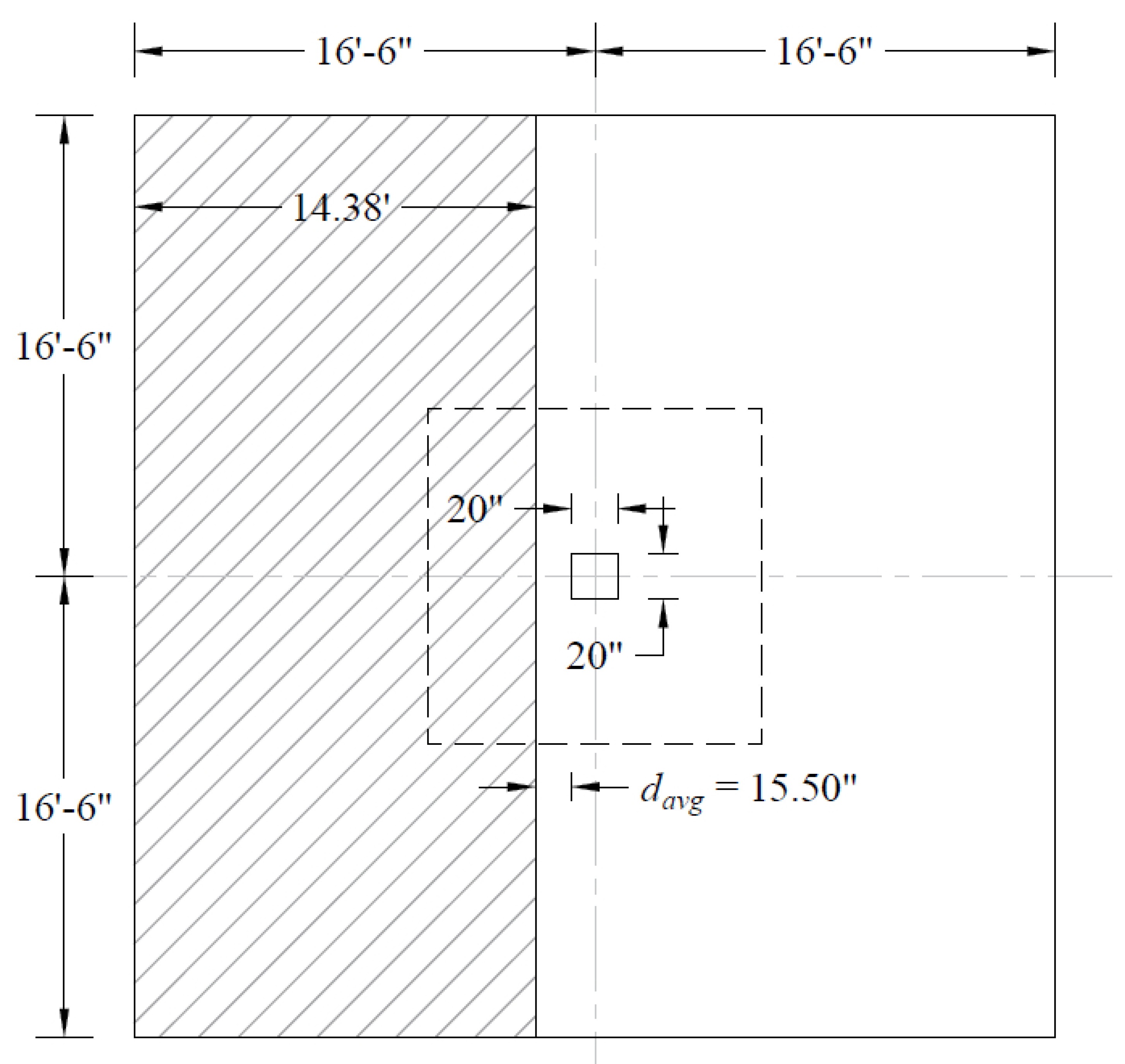

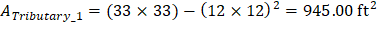

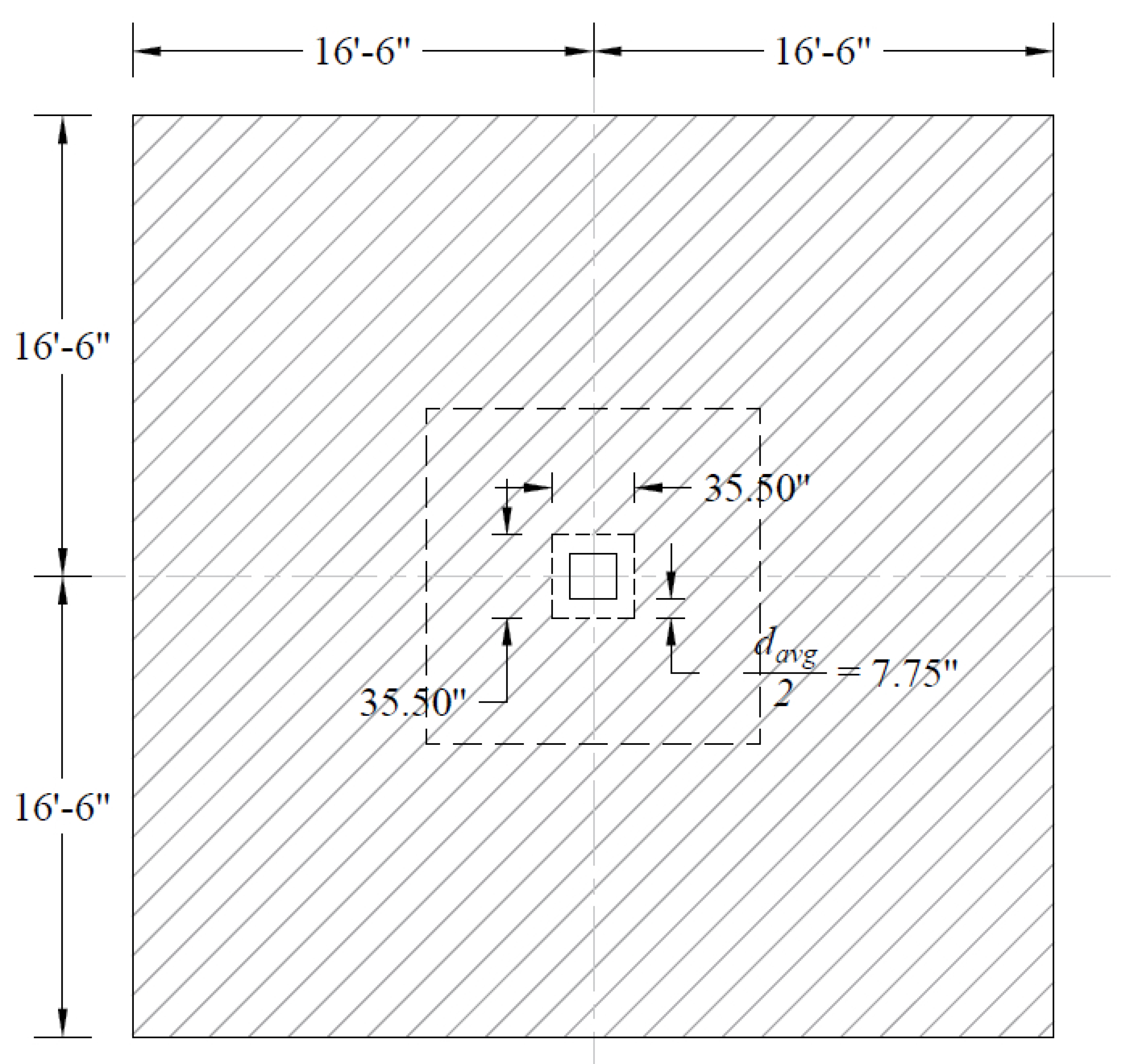

Check the adequacy of slab thickness for punching shear (two-way shear) at an interior column (Figure 4):

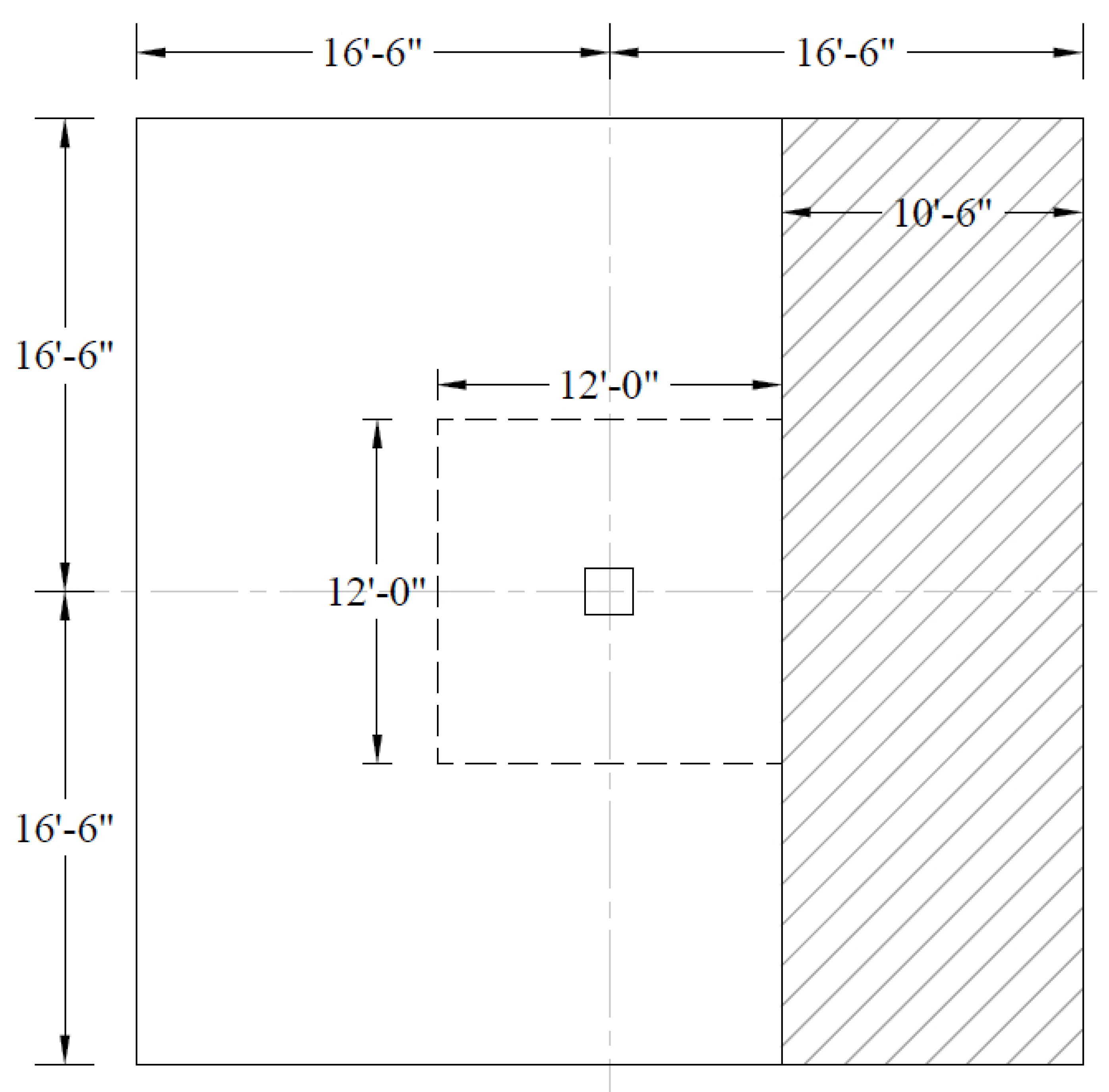

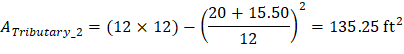

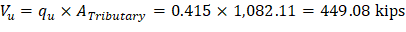

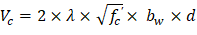

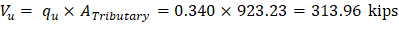

Tributary area for two-way shear is:

| |

| |

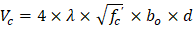

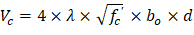

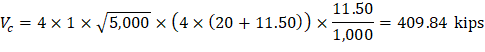

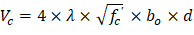

| ACI 318-14 (Table 22.6.5.2(a)) |

| |

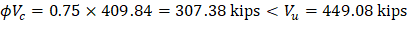

|

Slab thickness of 13 in. is not adequate for two-way shear. This is expected as the self-weight an applied loads are very challenging for a flat plate system.

Figure 4 – Critical Section for Two-Way Shear

In this case, four options can be considered: 1) to increase the slab thickness further, 2) use headed shear reinforcement in the slab, 3) apply drop panels at columns, or 4) use two-way joist slab system. In this example, the latter option will be used to achieve better understanding for the design of two-way joist slab often called two-way ribbed slab or waffle slab.

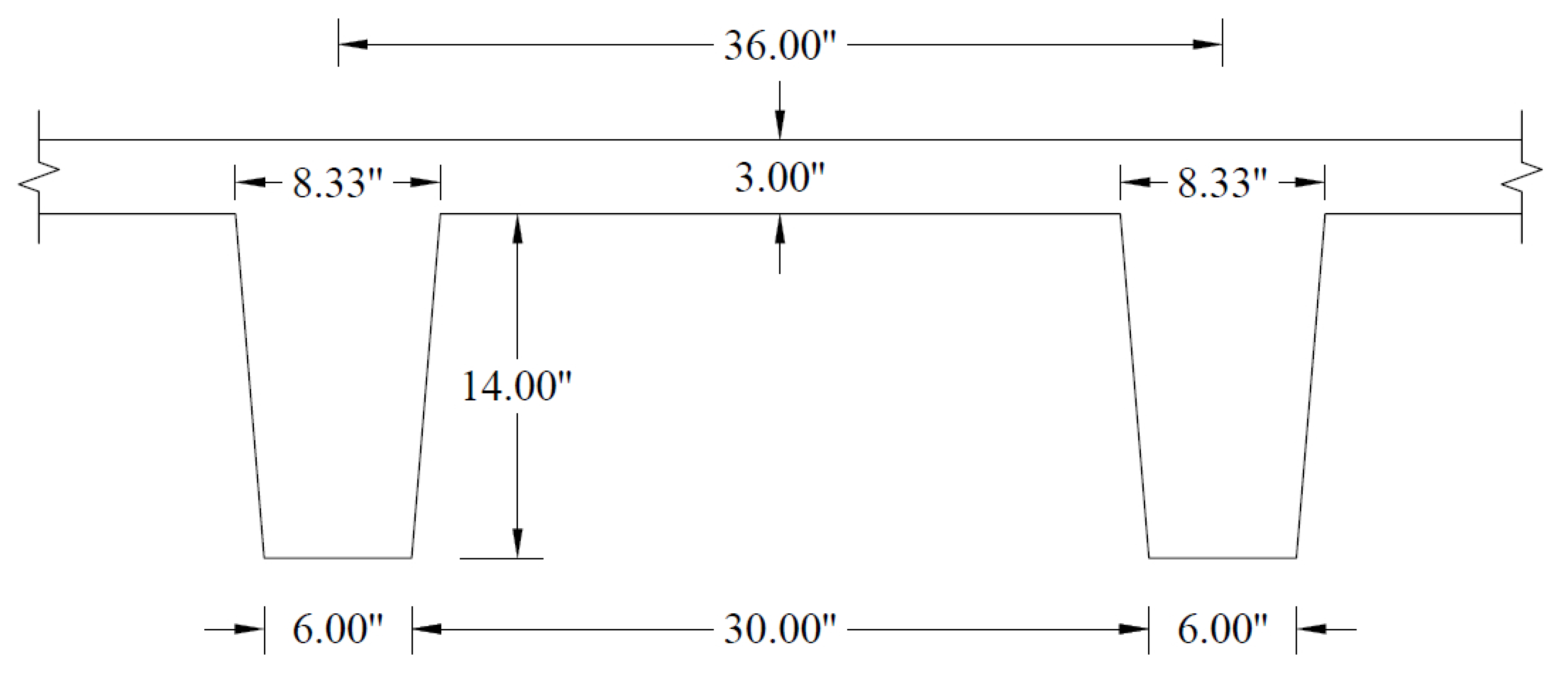

Check the applicable joist dimensional limitations as follows:

1) Width of ribs shall be at least 4 in. at any location along the depth. ACI 318-14 (9.8.1.2) Use ribs with 6 in. width. 2) Overall depth of ribs shall not exceed 3.5 times the minimum width. ACI 318-14 (9.8.1.3) 3.5 × 6 in. = 21 in. → Use ribs with 14 in. depth. 3) Clear spacing between ribs shall not exceed 30 in. ACI 318-14 (9.8.1.4) Use 30 in. clear spacing. 4) Slab thickness (with removable forms) shall be at least the greater of: ACI 318-14 (8.8.3.1) a) 1/12 clear distance between ribs = 1/12 × 30 = 2.50 in. a) 2 in. Use a slab thickness of 3.00 in. > 2.50 in.

Figure 5 – Joists Dimensions

In waffle slabs a drop panel is automatically invoked to guarantee adequate two-way (punching) shear resistance at column supports. This is evident from the flat plate check conducted using 13 in. indicating insufficient punching shear capacity above. Check the drop panel dimensional limitations as follows: | |

1) The drop panel shall project below the slab at least one-fourth of the adjacent slab thickness. | ACI 318-14 (8.2.4(a)) |

Since the slab thickness (hMI – calculated in page 9 of this document) is 12 in., the thickness of the drop panel should be at least: | |

hdp,min = 0.25 × hMI = 0.25 × 12 = 3.00 in. | |

Drop panel depth are also controlled by the rib depth (both at the same level). For nominal lumber size (2x), | |

hdp = hrib = 14.00 in. > hdp,min = 3.00 in. | |

The total thickness including the actual slab and the drop panel thickness (h) = hs + hdp = 3.00 + 14.00 = 17.00 in. | |

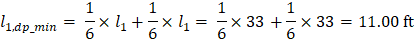

2) The drop panel shall extend in each direction from the centerline of support a distance not less than one-sixth the span length measured from center-to-center of supports in that direction. | ACI 318-14 (8.2.4(b)) |

Use

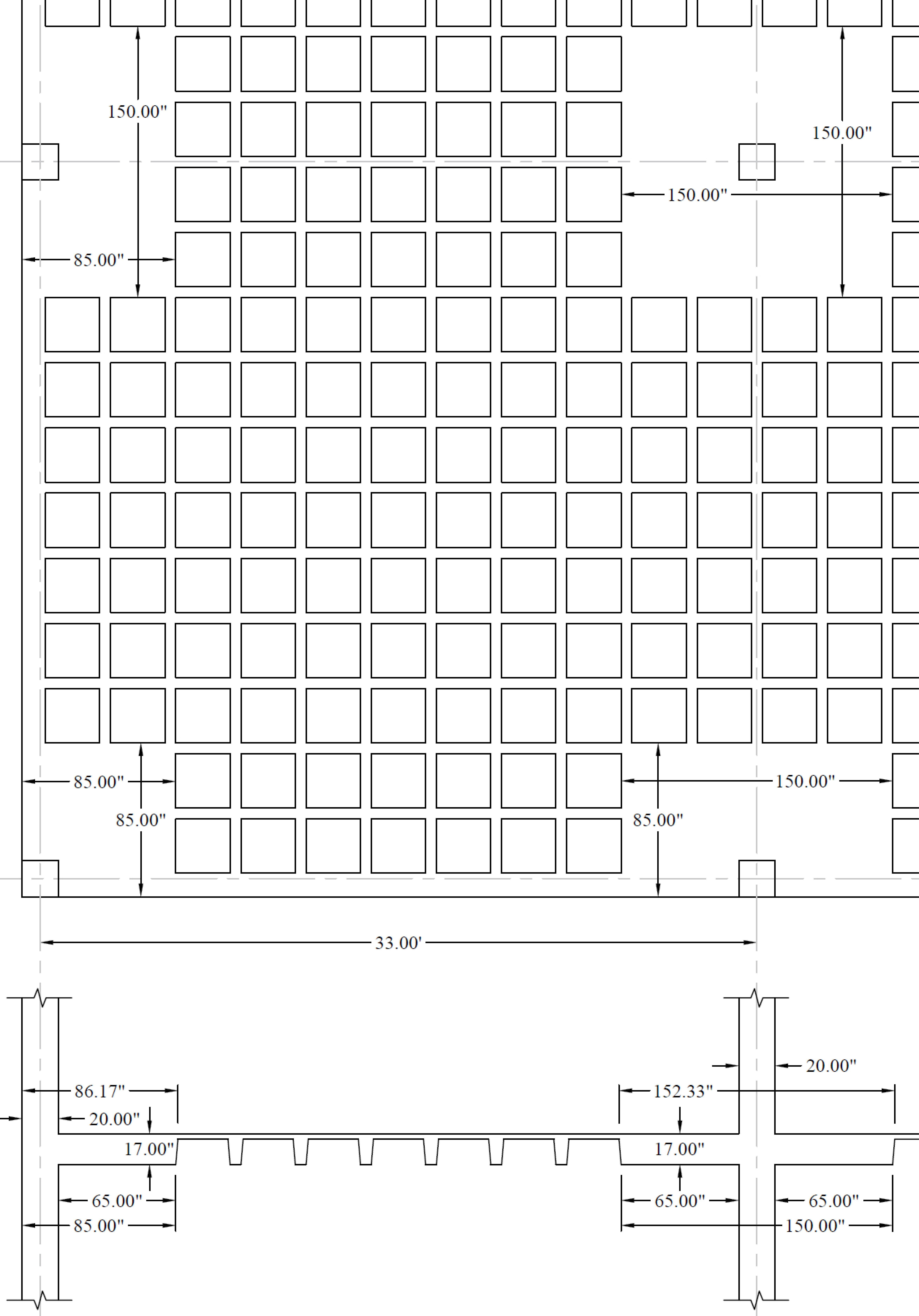

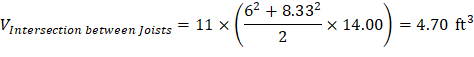

Based on the previous discussion, Figure 6 shows the dimensions of the selected two-way joist system.

Figure 6 – Two-Way Joist (Waffle) Slab

1.2. Preliminary Two-Way Joist Slab (Waffle Slab)

For slabs with changes in thickness and subjected to bending in two directions, it is necessary to check shear at multiple sections as defined in the ACI 318-14. The critical sections shall be located with respect to:

1) Edges or corners of columns. ACI 318-14 (22.6.4.1(a)) 2) Changes in slab thickness, such as edges of drop panels. ACI 318-14 (22.6.4.1(b))

1.2.1. Slab Minimum Thickness - Deflection

ACI 318-14 (8.3.1.1) |

In lieu of detailed calculation for deflections, ACI 318 Code gives minimum slab thickness for two-way construction without interior beams in Table 8.3.1.1.

For this slab system, the minimum slab thicknesses per ACI 318-14 are:

Exterior Panels: | ACI 318-14 (Table 8.3.1.1) |

But not less than 4 in. | ACI 318-14 (8.3.1.1(b)) |

Interior Panels: | ACI 318-14 (Table 8.3.1.1) |

But not less than 4 in. | ACI 318-14 (8.3.1.1(b)) |

Where ln = length of clear span in the long direction = 33 × 12 – 20 = 376 in.

For the purposes of analysis and design, the ribbed slab will be replaced with a solid slab of equivalent moment of inertia, weight, punching shear capacity, and one-way shear capacity.

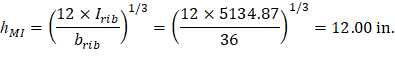

The equivalent thickness based on moment of inertia is used to find slab stiffness considering the ribs in the direction of the analysis only. The ribs spanning in the transverse direction are not considered in the stiffness computations. This thickness, hMI, is given by:

| spSlab Software Manual (Eq. 2-11) |

Where:

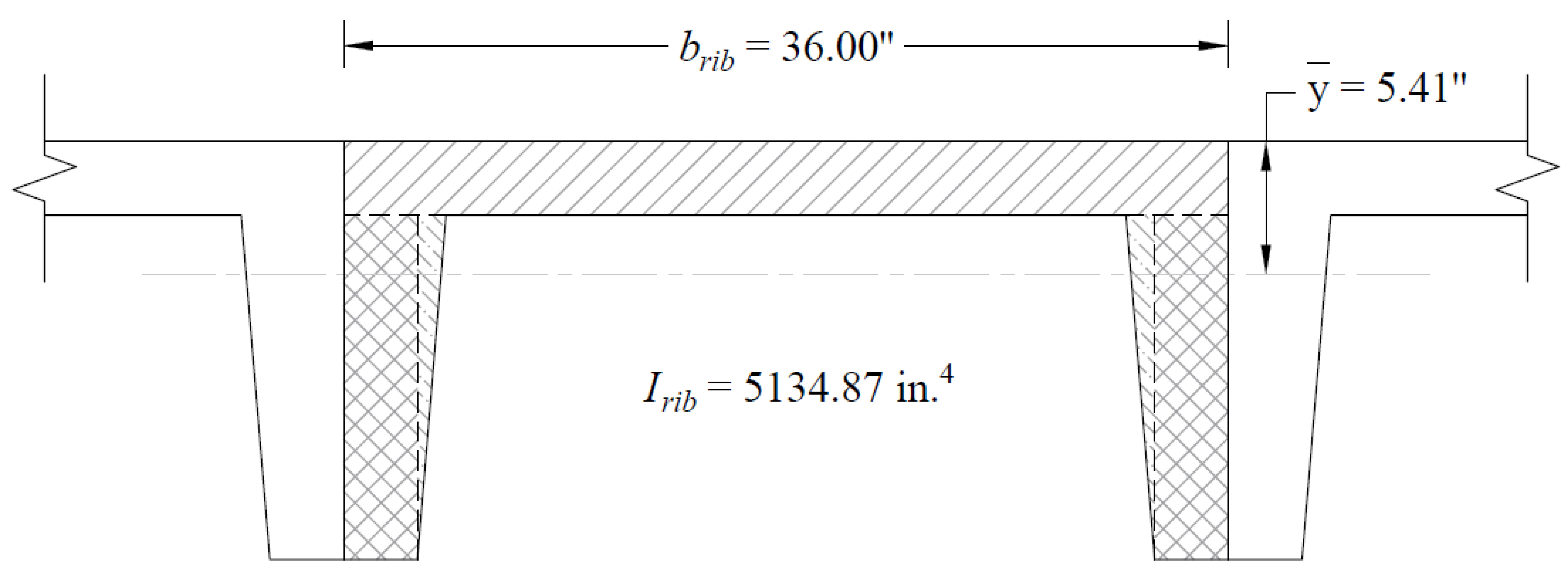

Irib = Moment of inertia of one joist section between centerlines of ribs (see Figure 7)

brib = The center-to-center distance of two ribs (clear rib spacing plus rib width) (see Figure 7)

Since hMI = 12.00 in. > hmin = 11.39 in., the deflection calculation can be neglected. However, the deflection calculation will be included in this example for comparison with the spSlab software results.

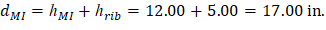

The drop panel depth for two-way joist (waffle) slab is set equal to the rib depth. The equivalent drop depth based on moment of inertia, dMI, is given by:

| spSlab Software Manual (Eq. 2-12) |

Where:

hrib = 3.00 + 14.00 – 12.00 = 5.00 in.

Figure 7 – Equivalent Thickness Based on Moment of Inertia

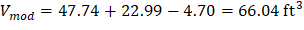

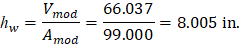

Find system self-weight using the equivalent thickness based on the weight of individual components (see the following Figure). This thickness, hw, is given by:

| spSlab Software Manual (Eq. 2-10) |

Where:

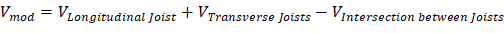

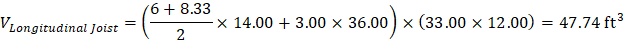

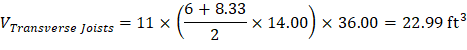

Vmod = The Volume of one joist module (the transverse joists are included – 11 joists in the frame strip).

Amod = The plan area of one joist module = 33 × 36/12 = 99.00 ft2.

Self-weight for slab section without drop panel = 150 pcf × 8.00 in. /12 = 100.057 psf

Self-weight for slab section with drop panel = 150 pcf × (14.00 + 3.00 - 8.00) in. /12 = 112.443 psf

Figure 8 – Equivalent Thickness Based on the Weight of Individual Components

1.2.2. Slab Shear Strength - One Way Shear

For critical section at distance d from the edge of the column (slab section with drop panel):

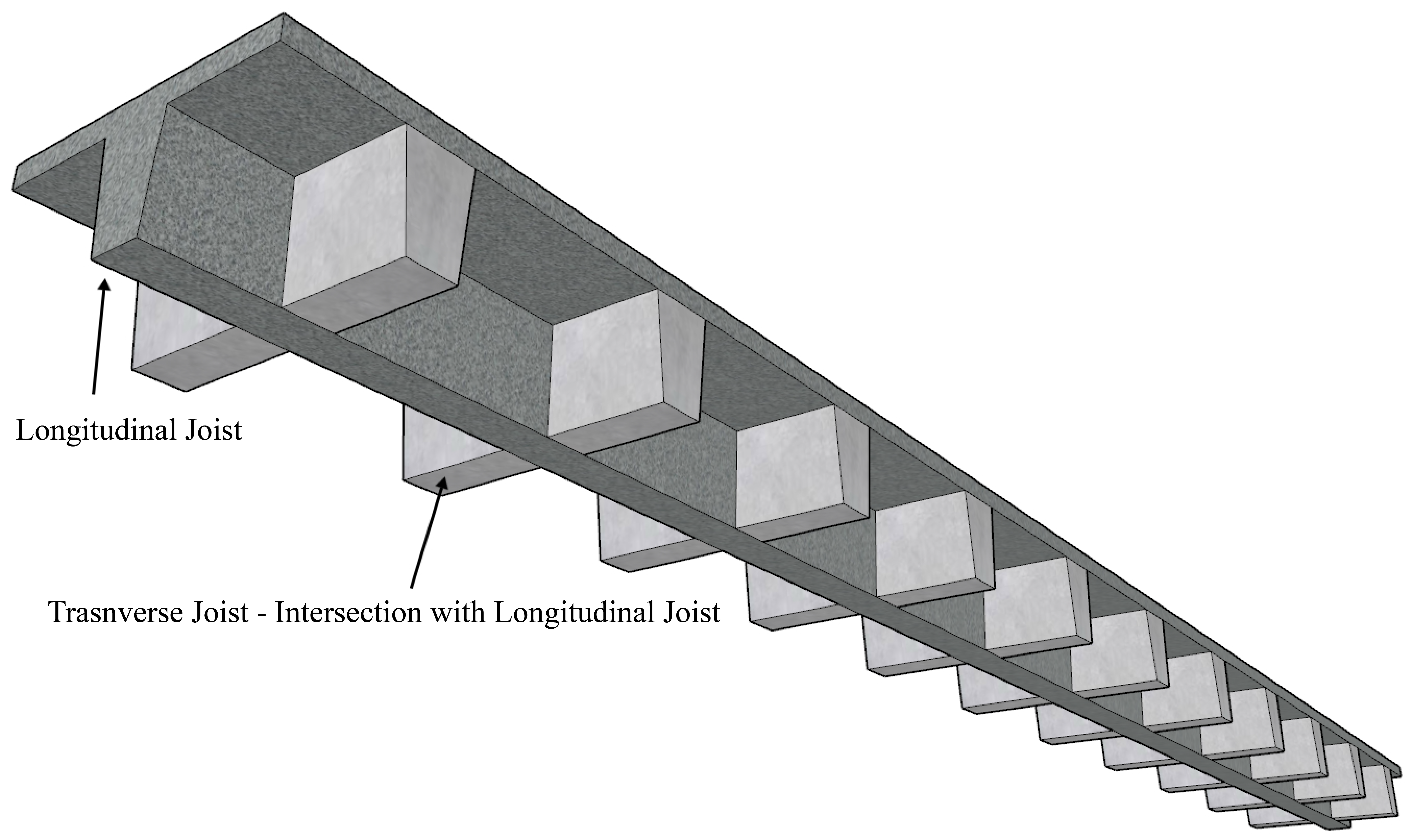

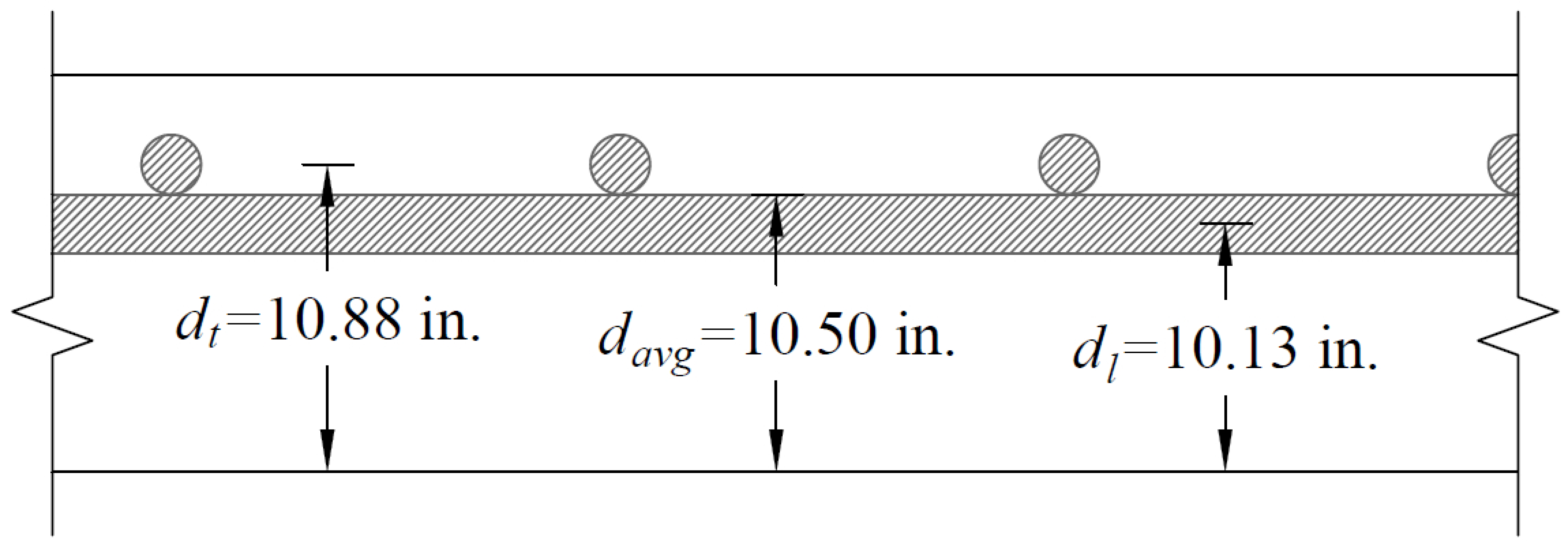

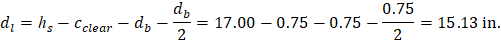

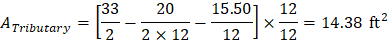

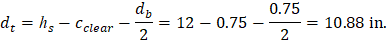

Evaluate the average effective depth:

| |

| |

|

Where:

cclear = 3/4 in. for # 6 steel bar | ACI 318-14 (Table 20.6.1.3.1) |

db = 0.75 in. for # 6 steel bar | |

hs = 17.00 in. = The drop depth (dMI) |

Figure 9 – Average Effective Depth for Slab Section with Drop Panel

Factored dead load, | ||

Factored live load, | ACI 318-14 (5.3.1) | |

Total factored load, |

Check the adequacy of slab thickness for beam action (one-way shear) from the edge of the interior column | ACI 318-14 (22.5) |

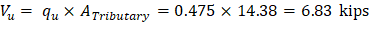

Consider a 12-in. wide strip. The critical section for one-way shear is located at a distance d, from the edge of the column (see Figure 10).

Tributary area for one-way shear is:

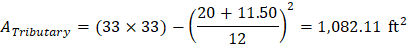

| |

| |

| ACI 318-14 (Eq. 22.5.5.1) |

where λ = 1 for normal weight concrete

Slab thickness is adequate for one-way shear for the first critical section (from the edge of the column).

Figure 10 – Critical Section at Distance d from the Edge of the Column for One-Way Shear

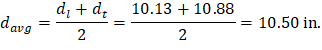

For critical section at the edge of the drop panel (slab section without drop panel):

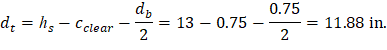

Evaluate the average effective depth:

| |

| |

|

Where:

cclear = 3/4 in. for # 6 steel bar | ACI 318-14 (Table 20.6.1.3.1) |

db = 0.75 in. for # 6 steel bar |

Figure 11 – Average Effective Depth for Slab Section without Drop Panel

Factored dead load, | ||

Factored live load, | ACI 318-14 (5.3.1) | |

Total factored load, |

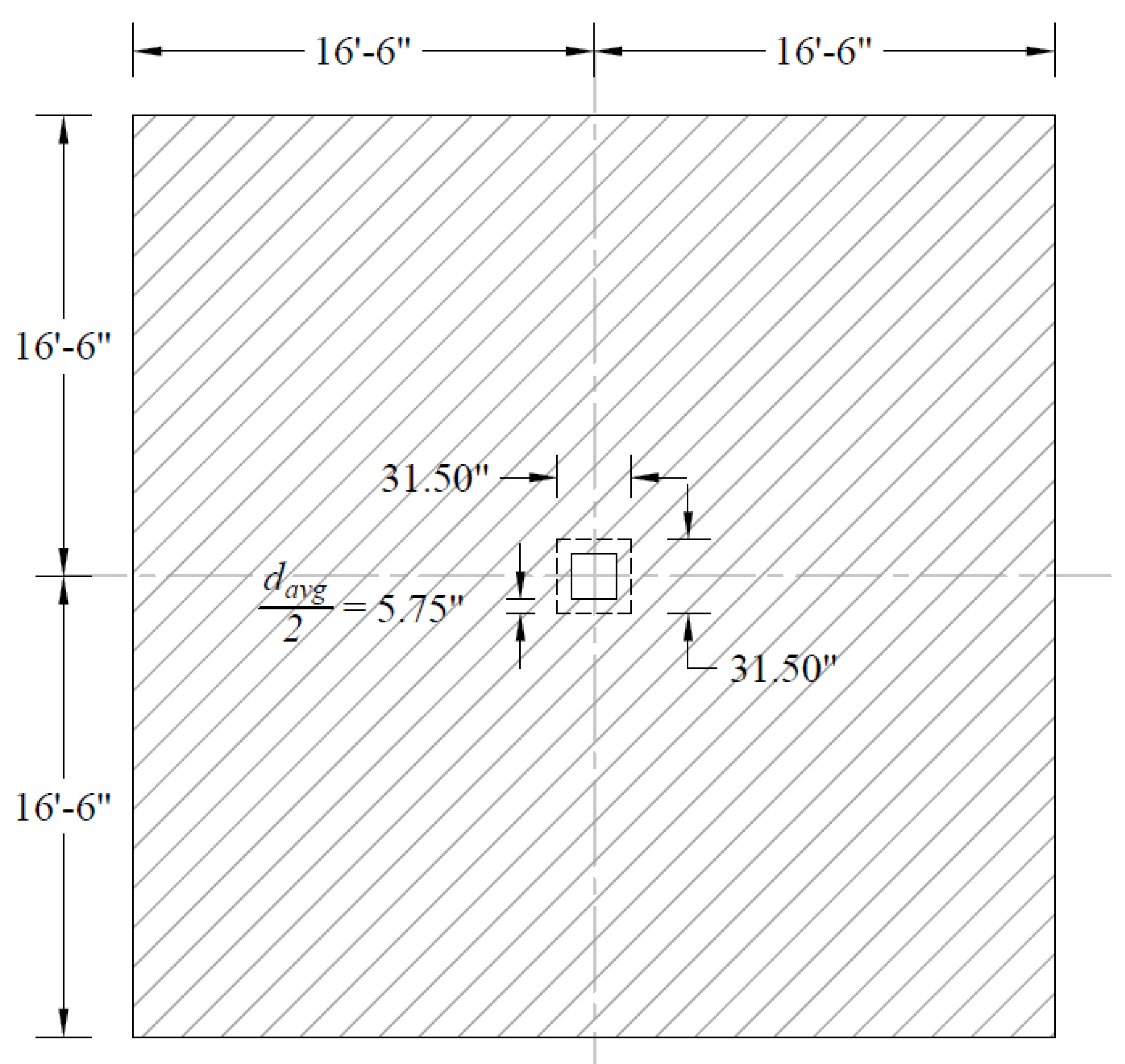

Check the adequacy of slab thickness for beam action (one-way shear) from the edge of the interior drop panel | ACI 318-14 (22.5) |

Consider a 12-in. wide strip. The critical section for one-way shear is located at the face of the solid head (see Figure 12).

Tributary area for one-way shear is:

| |

| |

| ACI 318-14 (Eq. 22.5.5.1) |

where λ = 1 for normal weight concrete

Slab thickness of 12 in. is adequate for one-way shear for the second critical section (at the edge of the drop panel).

Figure 12 – Critical Section at the Face of the Drop Panel for One-Way Shear

1.2.3. Slab Shear Strength - Two-Way Shear

For critical section at distance d/2 from the edge of the column (slab section with drop panel):

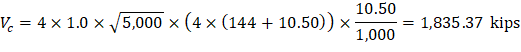

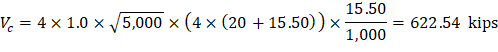

Check the adequacy of slab thickness for punching shear (two-way shear) at an interior column (Figure 13):

Tributary area of two-way shear for the slab without the drop panel is: Tributary area of two-way shear for the slab with the drop panel is: ACI 318-14 (Table 22.6.5.2(a))

(For square interior column)

(For square interior column)

Slab thickness is adequate for two-way shear for the first critical section (from the edge of the column).

Figure 13 – Critical Section at d/2 from the Edge of the Column for Two-Way Shear

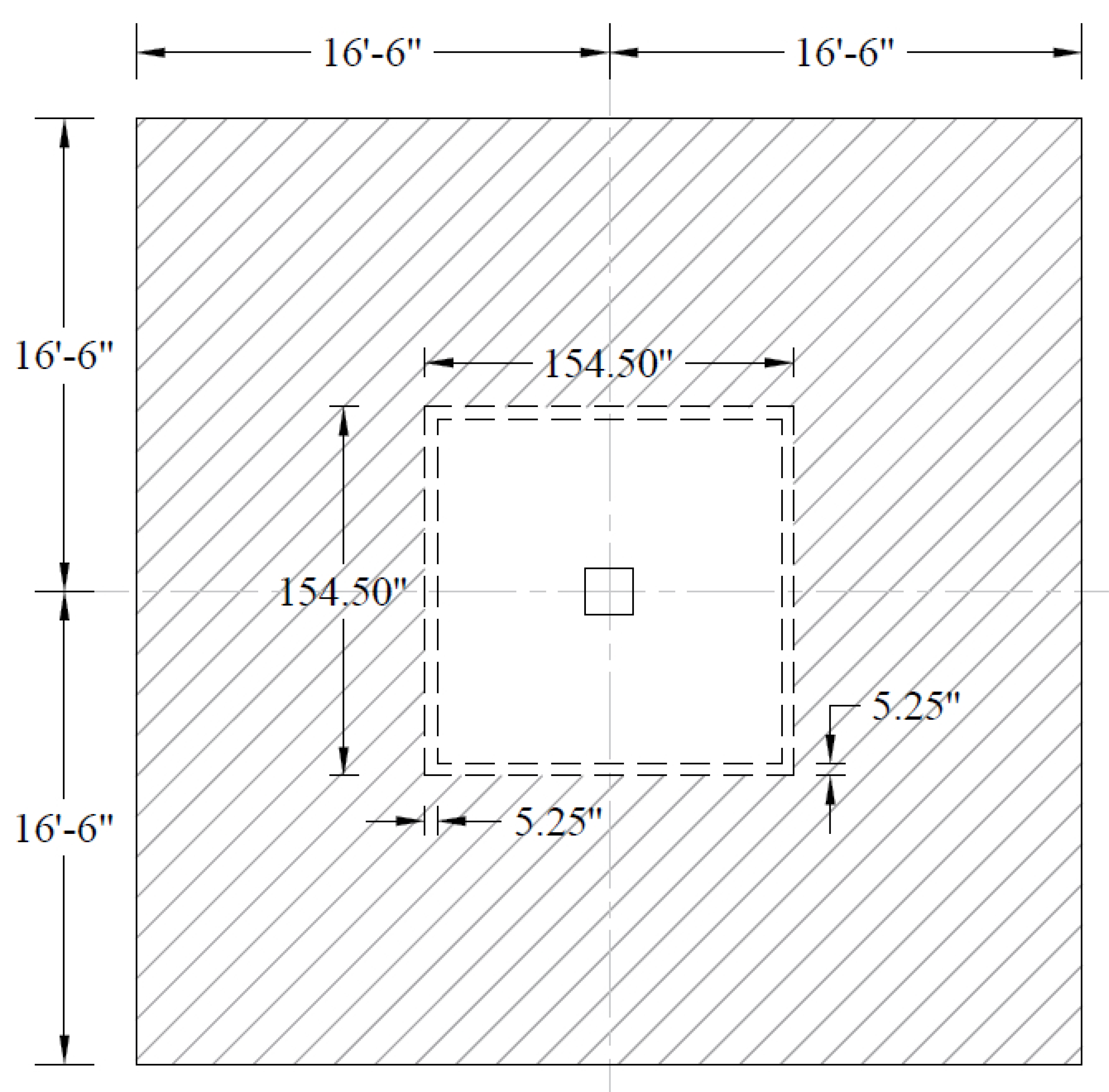

For critical section at the edge of the drop panel (slab section without drop panel):

Check the adequacy of slab thickness for punching shear (two-way shear) at an interior drop panel (Figure 14):

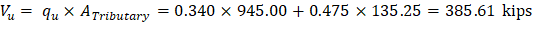

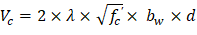

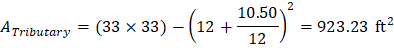

Tributary area for two-way shear is:

| |

| |

| ACI 318-14 (Table 22.6.5.2(a)) |

| |

|

Slab thickness of 12 in. is adequate for two-way shear for the second critical section (from the edge of the drop panel).

Figure 14 – Critical Section at d/2 from the Edge of the Drop Panel for Two-Way Shear

1.2.4. Column Dimensions - Axial Load

Check the adequacy of column dimensions for axial load:

For live load, superimposed dead load, and self-weight of the slab around an interior column:

qu = 340.07 psf (on page 14)

For self-weight of additional slab thickness due to the presence of the drop panel around an interior column:

qu = 475.00 – 340.07 = 134.93 psf (see page 12 and page 14)

Assuming four story building

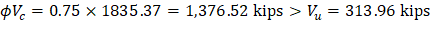

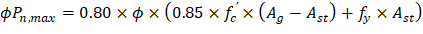

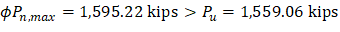

Assume 20 in. square column with 12 – No. 11 vertical bars with design axial strength, ϕPn,max of

| ACI 318-14 (22.4.2) |

| |

| |

Column dimensions of 20 in. × 20 in. are adequate for axial load.

(For square interior column)

(For square interior column)

(For square interior column)

(For square interior column)